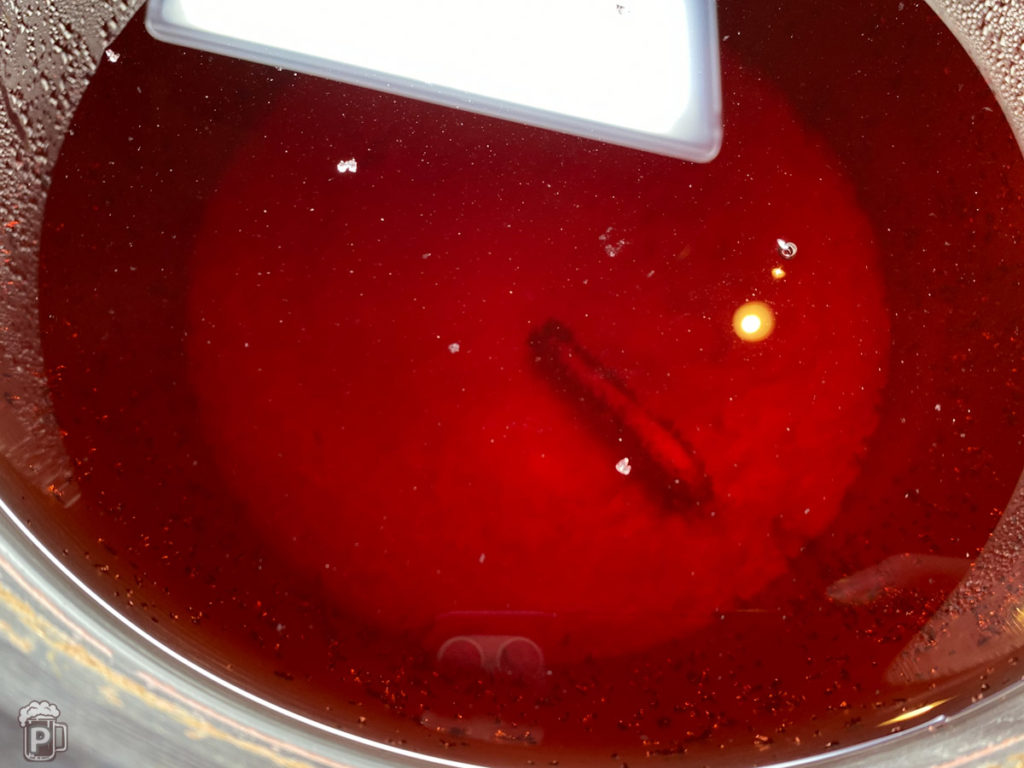

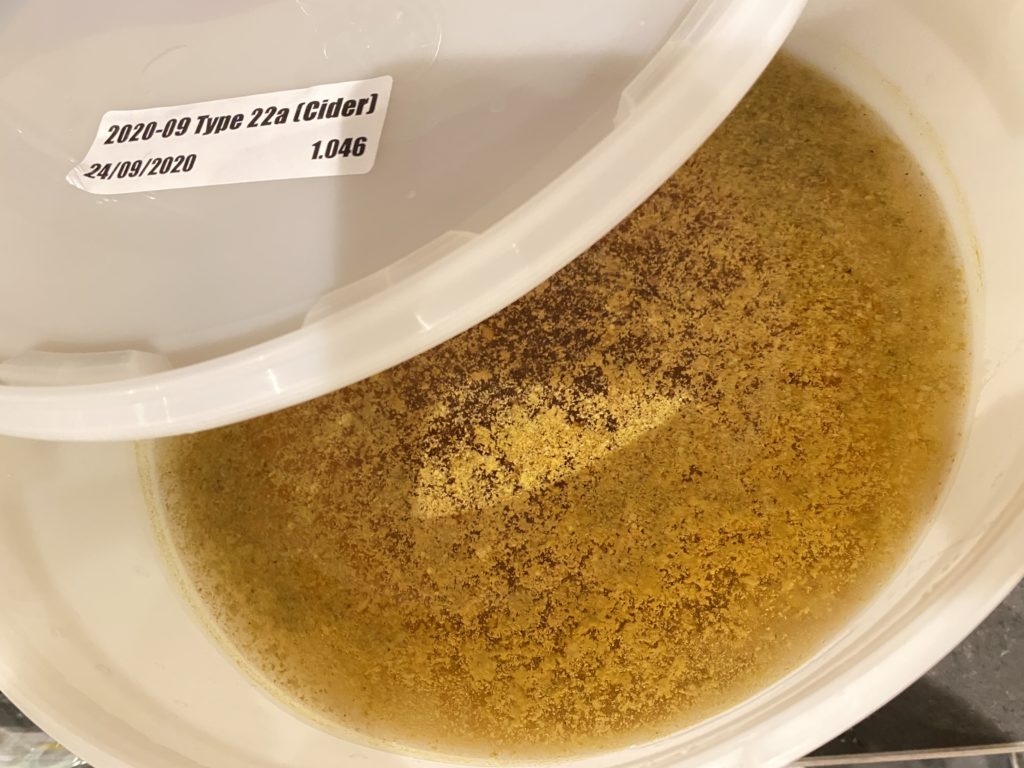

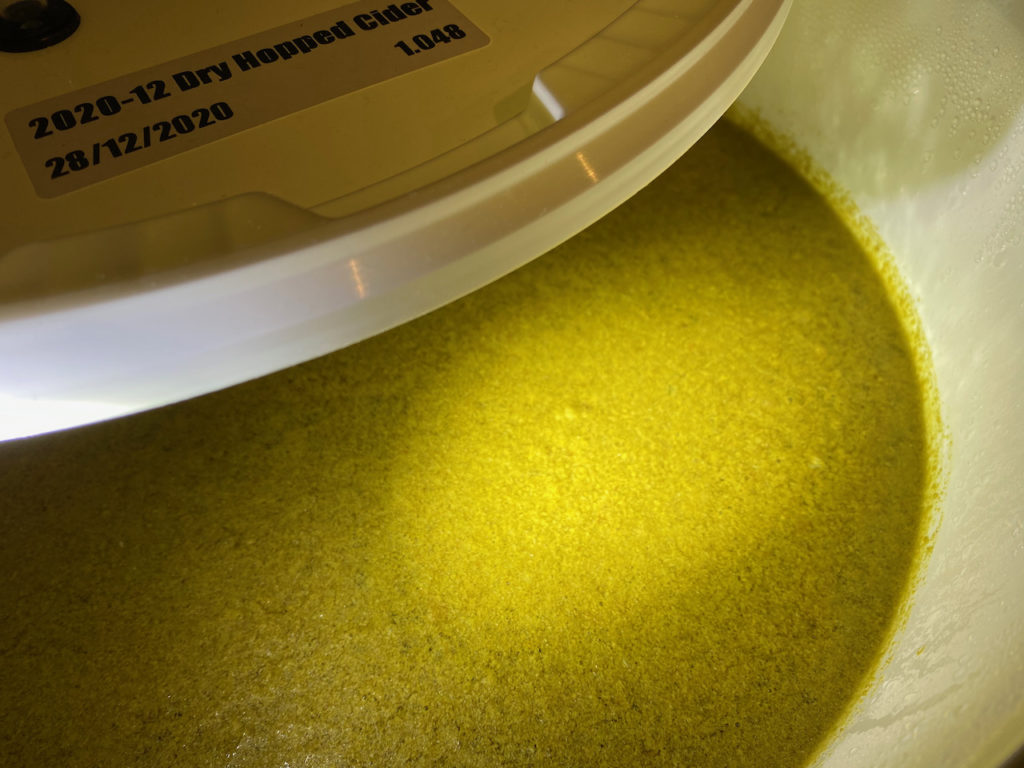

A late session today saw me putting away the S&B cider 7 days after starting primary. The flavouring was added 24 hours ago so it’s too late to worry whether or not I should have left it for another couple of days, time to get it packed.

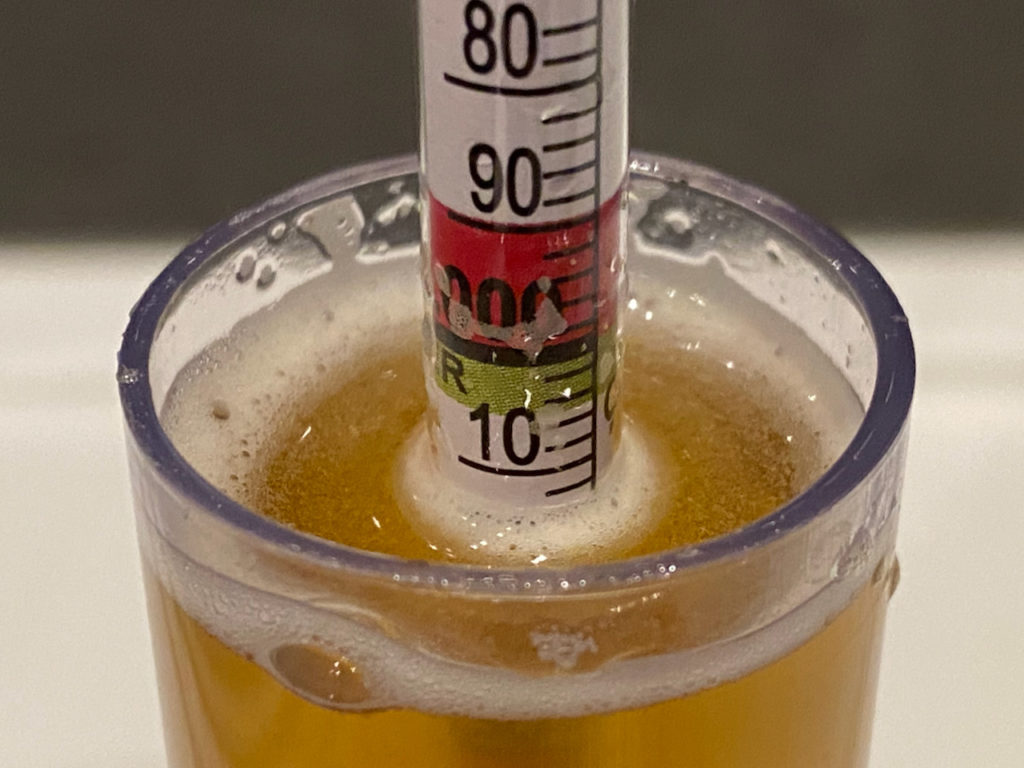

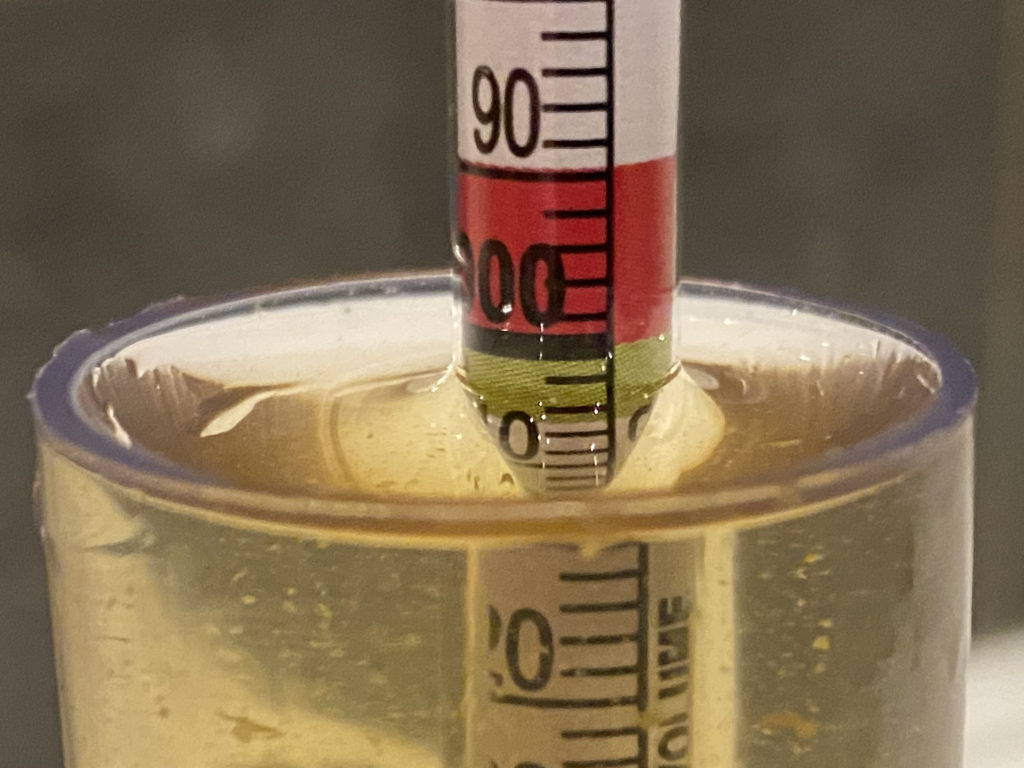

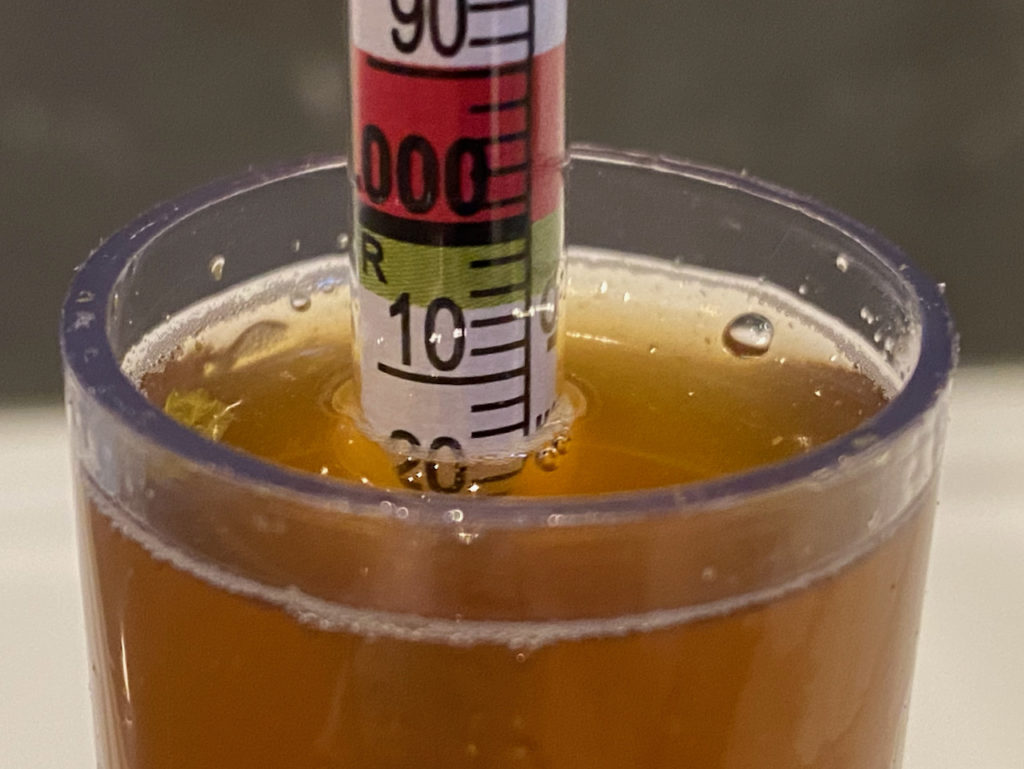

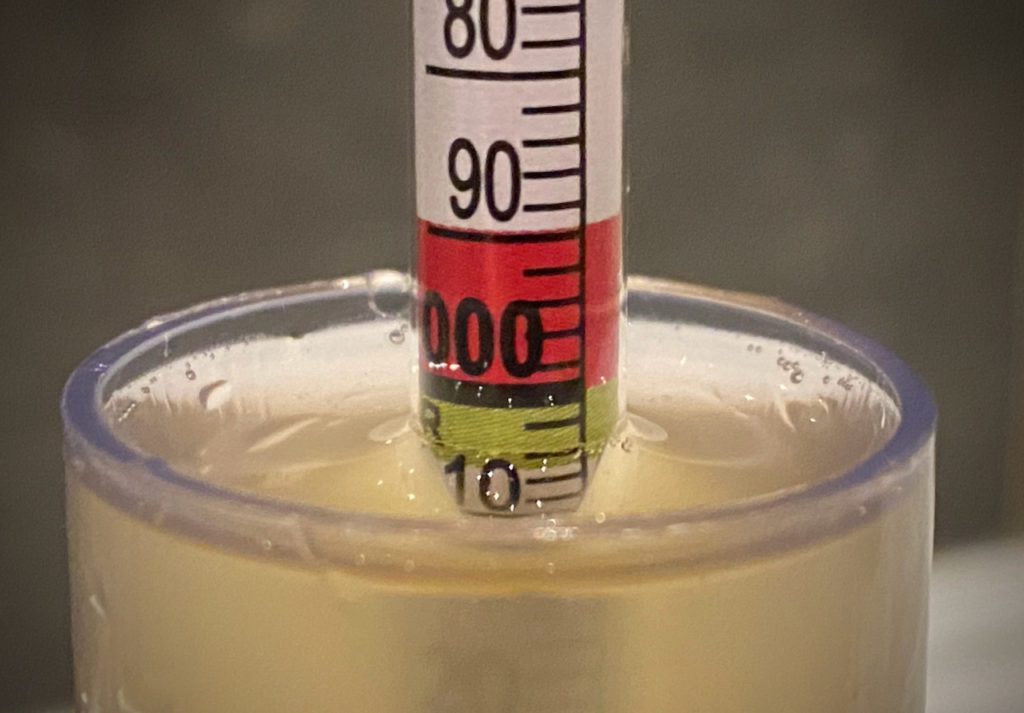

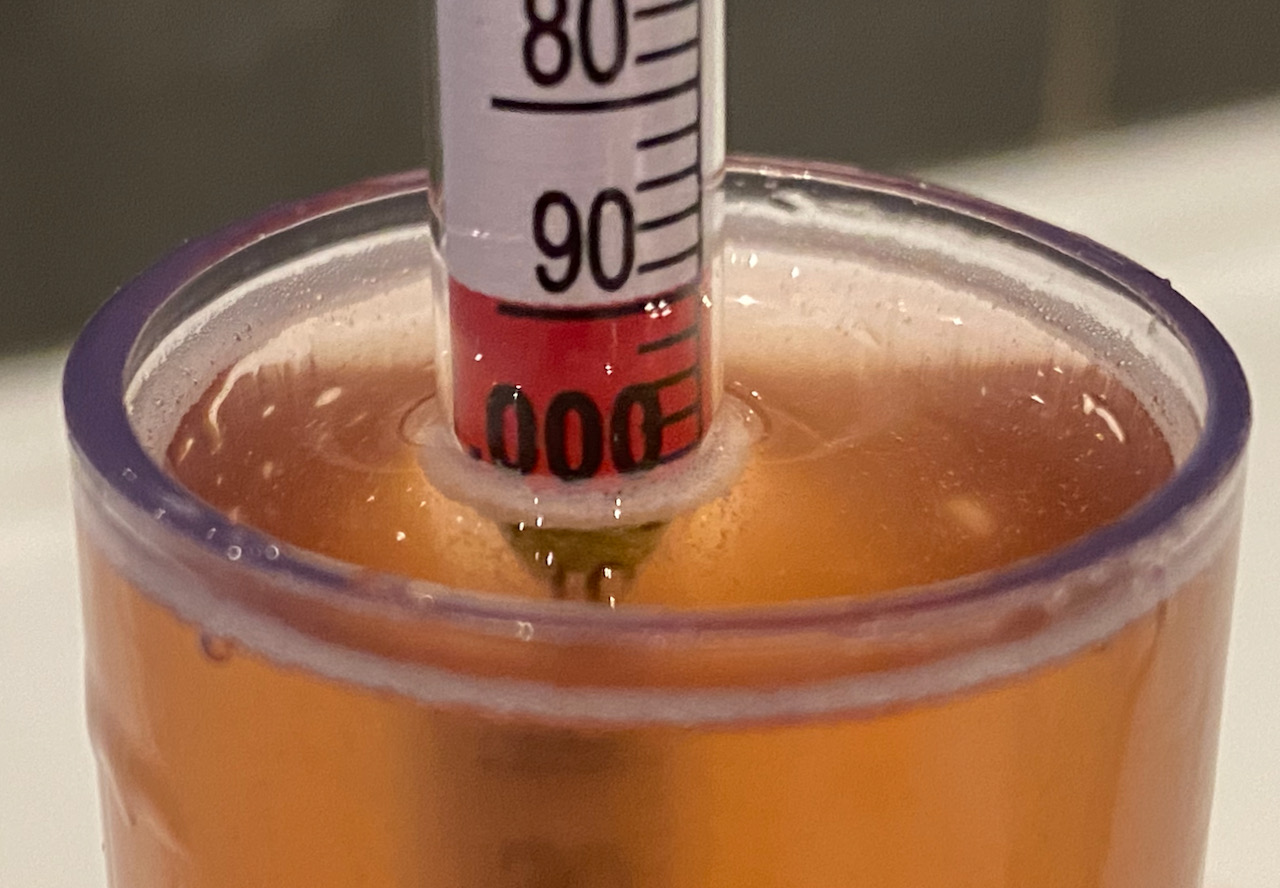

I started by taking another gravity reading out of habit, although I suspected it might be invalid with all that flavouring in there. Wasn’t disappointed – she registered 1.013 which I’m taking as additional non-fermenting sugar (i.e. the sachet of pear and strawberry flavour concentrate) combined with no further fermentation of what was already in there. I’m therefore recording the reading of 1.013 on this log but using 1.011 from yesterday as the final gravity, producing 5.25% ABV against an expected 4.7%. Had we made it all the way to 1.007 we’d be looking at 5.78%. Yikes!

All Change

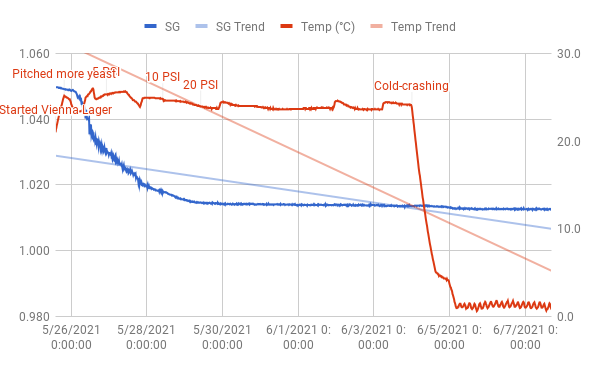

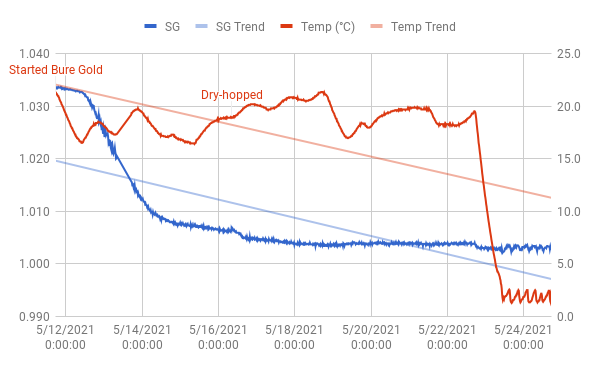

With the sample taken it was time to set up the racking cane / auto syphon as usual, and while doing so I decided to do two things differently this time: fill one of my small kegs and carbonate with CO2 in order to see if it impacts the taste compared to primed bottles, and try out my new Blichmann Beer Gun on its first bottling run.

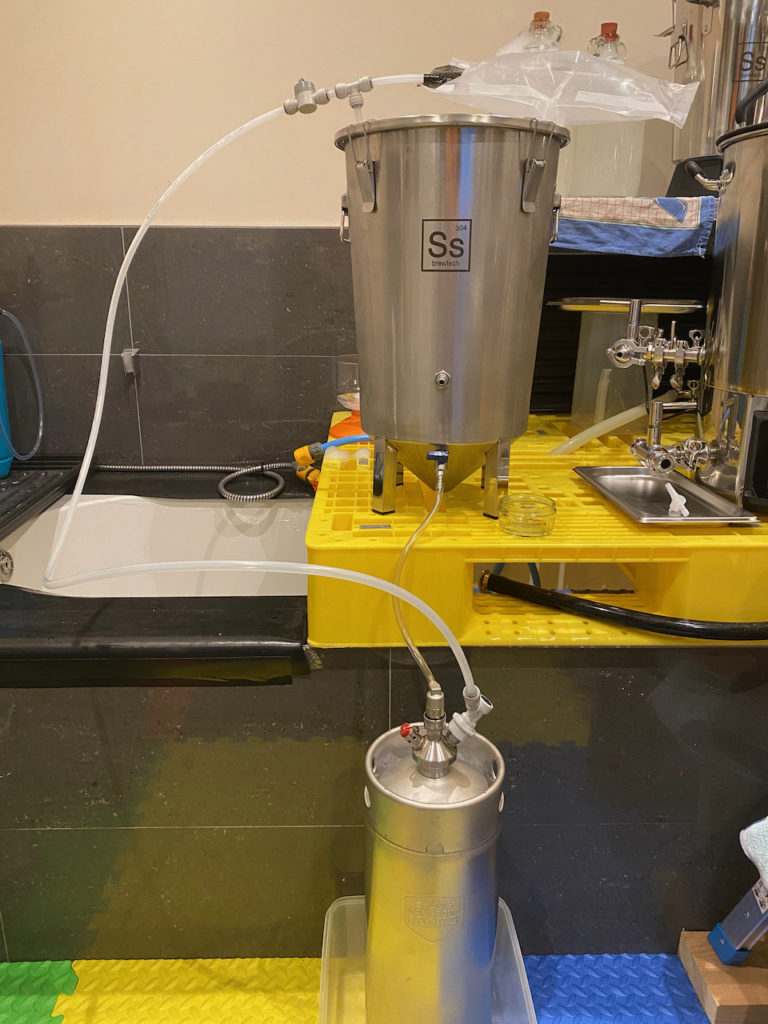

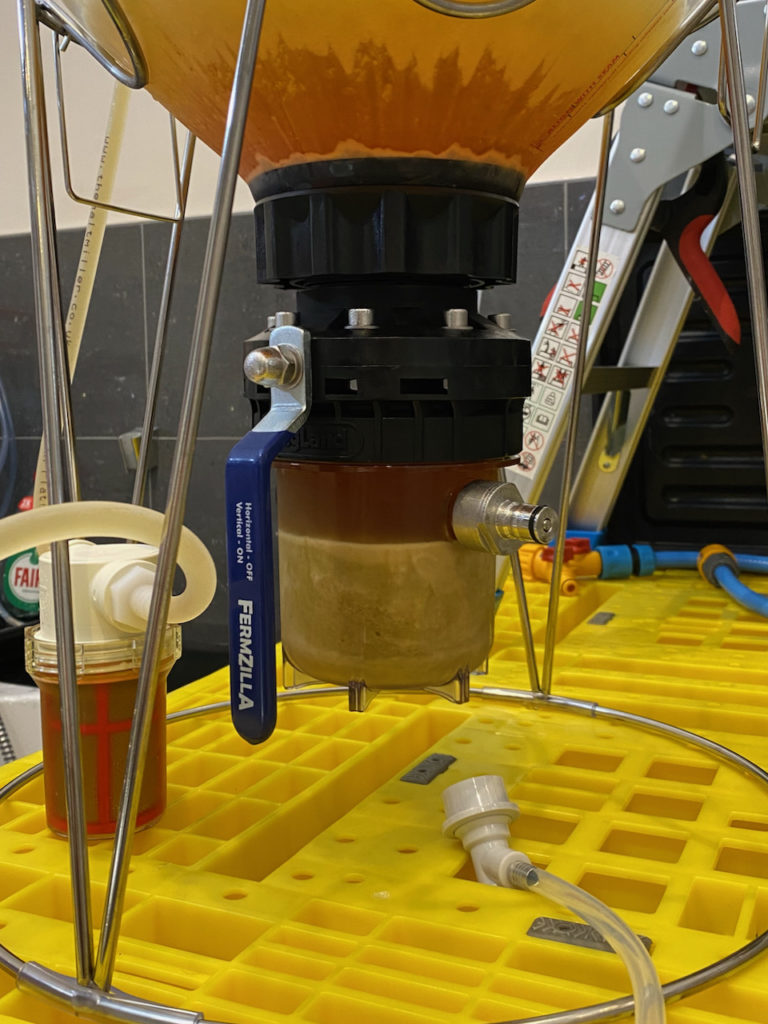

I cleaned and sanitised a 5 litre mini keg but didn’t bother purging it with Star San and then CO2 as I would while doing a closed transfer from the Fermzilla, as there seemed little point in trying to keep oxygen out when racking from an open bucket. Instead I filled it to within a couple of inches from the top using the bottling cane and then cranked it to 30 PSI before popping the PRV a couple of times (may as well get some oxygen out) and putting it in the fridge next to my other 5 litre keg containing the last of my Bure Gold. Time to try out that Beer Gun.

A Small Error

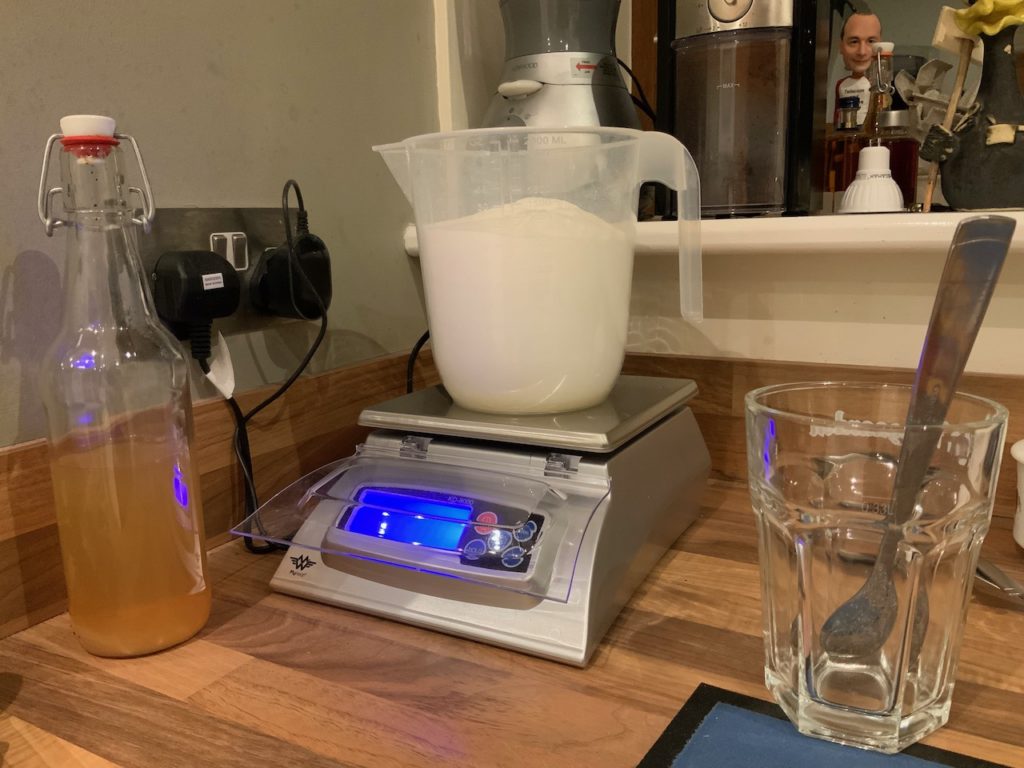

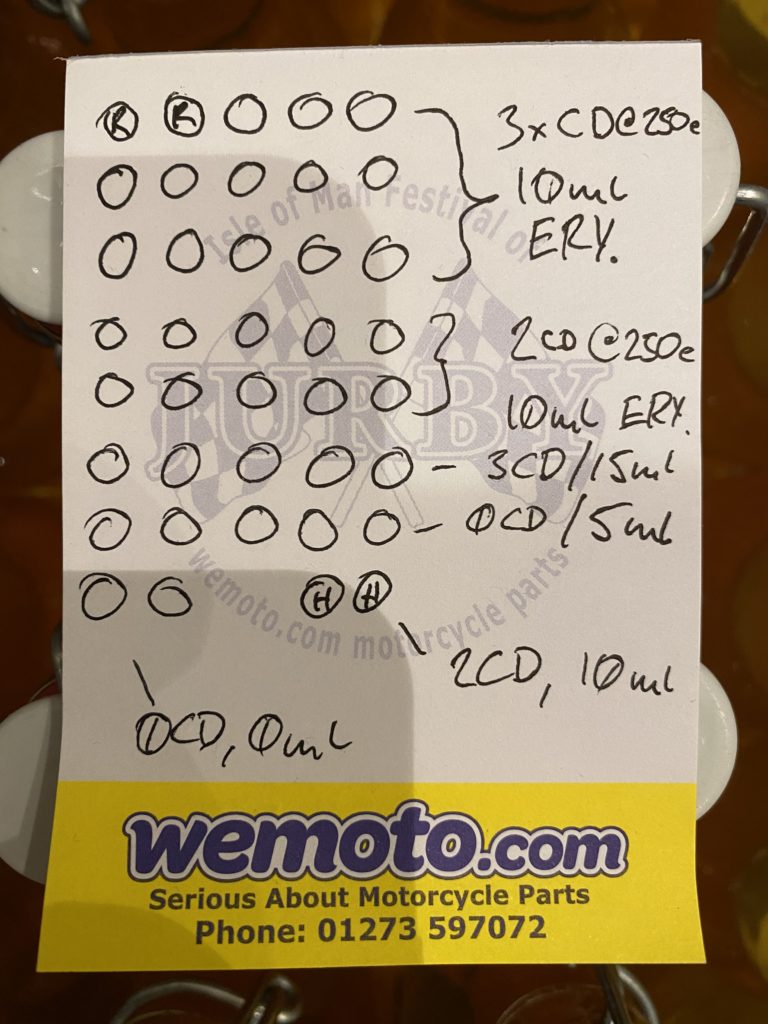

A cursory glance at the new gadget showed it came with a black disconnect, so I started by racking the remaining cider into a clean 19 litre Cornelius keg using the still connected bottling cane. It looked to be around 17 litres and since I was almost out of carbonation drops I decided to weigh two of them, the recommended dose per 500ml bottle, and multiply the resulting 5g by 17 to tell me how much dextrose I need to add. That was around three hours ago, and it’s only now that I’ve pulled up the Beer Priming Calculator in order to see if my quantity of priming sugar tallies with Brewer’s Friend that I’ve spotted the mistake: there’s two bottles per litre not one. I’ve therefore added half as much as I should have, which explains why Brewer’s Friend recommends 160g of Dextrose for a fruit lambic – about the closest to cider in my opinion. Oh well, looks like it’ll be a slightly sparkling cider this time around.

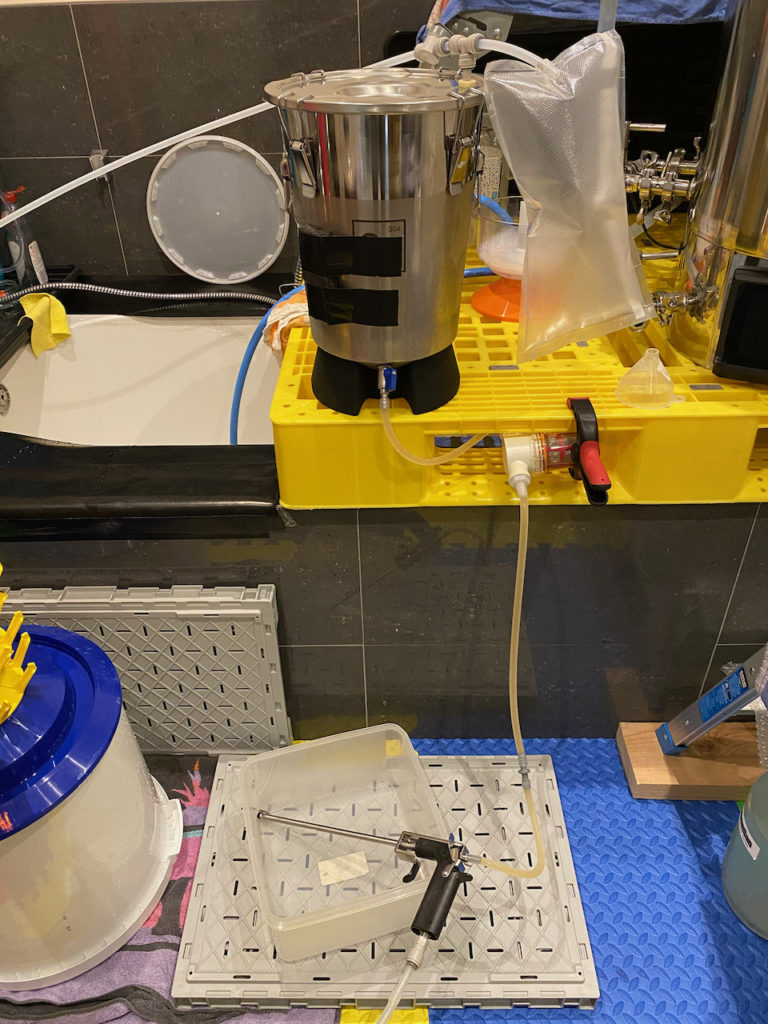

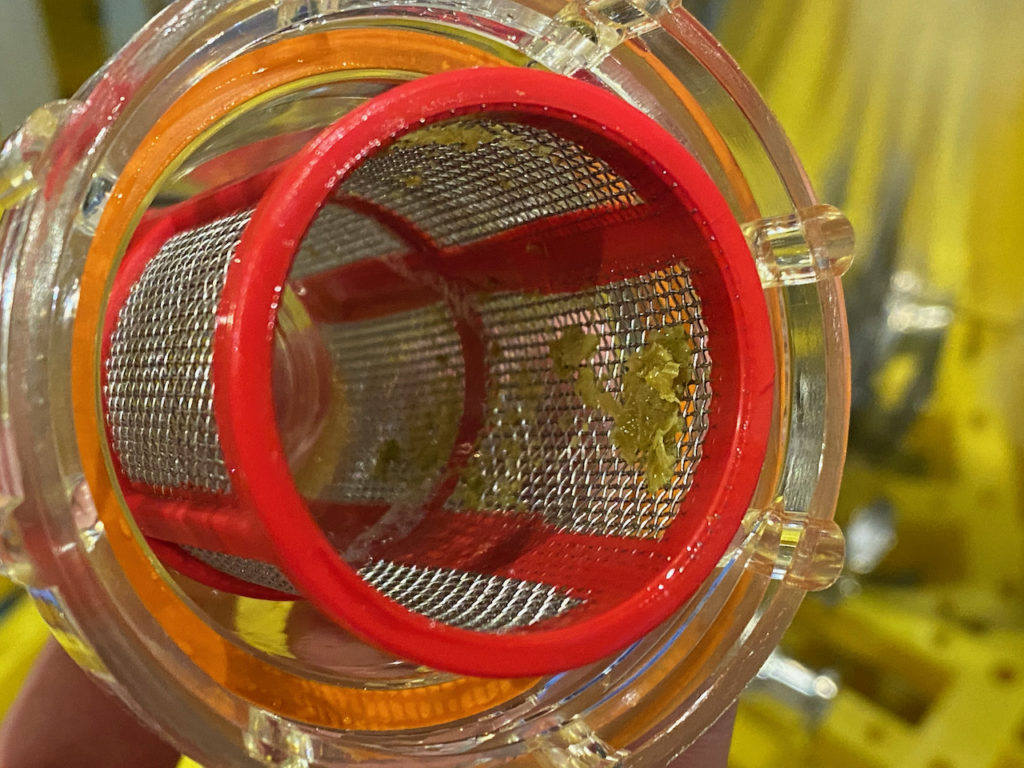

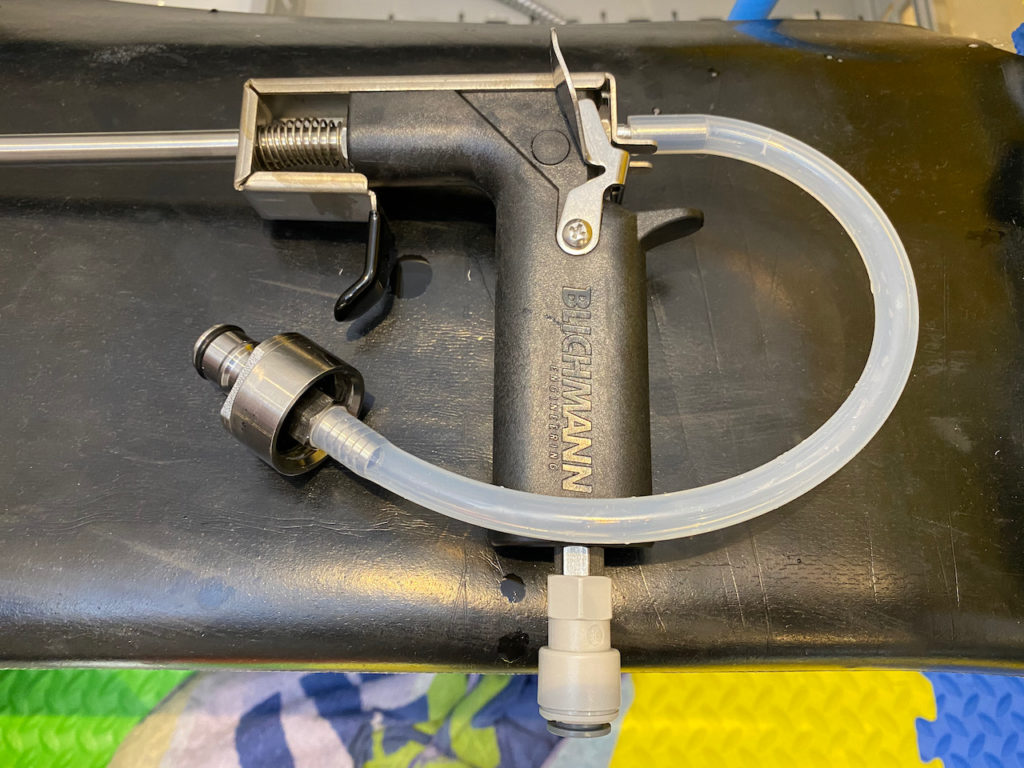

That was three hours ago and I carried on in blissful ignorance, adding the sugar to the Corny keg as the bucket emptied. Once I had all the cider I was going to get from the bucket I capped the keg and hooked up the gas, again popping the PRV a couple of times in order to dump some oxygen from the top of the vessel. The beer gun was quickly taken apart for inspection and sanitation, and I saw the first problem: the gas line was designed to screw onto a male regulator post, which I didn’t have. I did have a John Guest T-piece and some more beer / gas line, so I used that instead of the gas line that came with the beer gun. Not ideal since it’s quite stiff and made the process unnecessarily cumbersome, but I was determined to try it out.

Ready … Aim …

Once back together the beer gun worked very well, letting me purge oxygen from each bottle before filling it to the top and purging some more while drawing out the nozzle, then capping straight away. I think it’s a very slick tool and once I’d cranked up the pressure to around 15 PSI I was able to fill bottles at a good rate, though doing this with partially carbonated beer straight from the Fermzilla might require a bit more experimentation as there’s bound to be some foam, whereas the cider was totally placid. Might end up using a fair bit of gas though, so perhaps reserve it for ultra-hoppy beers?

Then again, this is the first bottling run following my first kegging session, and I’m inclined to agree with everyone who sings the benefits of kegging thanks not only to the superior taste of draught, but also due to the simplicity and speed of the kegging process compared to cleaning bottles, filling them while watching out for oxygen, capping them, and washing up afterwards.

And if you cock up the carbonation it’s as easy as cranking up the regulator.