I just pulled a pint from the main 19l Corny keg, and there’s quite a good head on it with plenty of body underneath. With that it’s been 5 days at 15 PSI of pure CO2, and it’s just about perfect.

Tag Archives: carbonation

I’m switching the Irish Stout kit beer from CO2 onto Beer Gas (60/40) because I also need to put on a traditional English bitter that’s been liberated from somewhere else, and doesn’t want any carbonation. This means that the stout will have been on CO2 at 15 PSI for 6 days now, and although I haven’t tried it yet I reckon it’ll be about right. Will give it a taste when I run out of Yeti imperial stout, finish the two 5 litre kegs of stolen bitter, or fit a fourth tap. Watch this space …

Had a sneaky glass of this today, but it’s blatantly not ready after 6 days at 12 PSI so I’m cranking it to 16 PSI and momentarily disconnecting the other kegs in the kegerator. Glad I’ve got a manifold with separate taps, shame I haven’t got separate regulators.

Taste is pretty good here now that it’s had 3 weeks to condition fully, but I’m slightly underwhelmed by the lack of carbonation. There’s a hint of head, some very slight fizz on the tongue, but all said & done it’s not quite enough for a lager. I think next time we can increase it to 2g of Dextrose for those 330 ml bottles, maybe even 2.25g.

It’s been a month since this was moved out into the cold, thought I’d neck a cheeky one to see if we’re onto a winner or if I’ll be handing out duds at the July shoot. Glad to say that it’s just fine; only the very faintest hint of twang on the nose and palate, maybe a touch too much carbonation at first but it soon settles down – unlike that Grapefruit IPA I’ve still got knocking about somewhere.

I seem to remember from my first taste of Bure Gold, another one that will be handed out in July, that it wasn’t quite ready yet, and could do with a few more weeks. Well, Wherry has now had a month of conditioning and Bure Gold just two weeks, so I’m going to make a note to check in on BG on 1st July.

Having given one of these to Chris @ Bottle Monkey last week I wanted to try another one, just to see how much different it is from the draught version. 14 days of conditioning doesn’t sound like a lot for such a big beer and I was worried I’ve given away a dud, but thankfully all the flavour is there, as is the nose, and without any twang. The only downside is that there doesn’t seem to be the same level of carbonation. It’s not totally flat, and probably OK for a stout, but there’s just no head as you pour right until the very end, at which point you get a very thick slick of bubbles that barely covers the surface. Compare that to the velvety hat of creamy goodness you’ll find on the draught version and it appears to be a very different beer, even if they’re almost identical (below the surface) once left to settle. Maybe try for more carbonation next time?

As Twisty Listy has just run out and freed up a line in the Kegerator I thought it’d be rude not to hook up Yeti and sample a small thimble. The result: great taste, almost no carbonation. To be fair I’m using my most aggressively throttled line, with just a small section of 3/8 at each end connected by about 3 feet of 3/16, but that should just result in less foam in the glass, not less carbonation altogether.

Brewfather reckons 10.6 PSI @ 5℃ for a week to get to 2.3 vols and she’s been sitting at approximately 11 PSI for 6 days, so in an effort to get her ready for the weekend I’ve turned off the other 2 kegs (both variants of Thirst Scratch) at the manifold and cranked Yeti up to 30 PSI. Let’s give it 12 hours.

I started this keg at 30 PSI three days ago, and when I checked the pressure just now it was down to just under 10. I’m putting this down to there not being a great deal of head-space in the keg and to it not being connected up to anything in that time.

The beer tasted OK. Not fantastic but certainly not bad; reasonable amount of bitterness and a good whiff of hops, but not as strong in the citrus department as I’d have liked. Clarity also was a little way behind where it should have been given the period spent cold-crashing (and subsequently carbonating at the same temperature) but then again this was the first pour from that keg so there may have been some deposits in there.

It did seem a little bit flat, so I upped the pressure again to 30 PSI now that there’s another pint of head space, will check back in a couple of days.

Thanks to a mix-up at bottling time yesterday, the 31 mixed bottles only have 50% of the priming sugar that they should, and today I corrected that by cracking some of the bottles open again and adding the last of my carbonation drops. The 31 bottles of Mangrove Jack’s Strawberry & Peach Cider now look like this:

- 10 metallic red crown caps: 85g of dextrose per 17 litre batch, so around 2.5g per bottle – roughly 50% of what’s appropriate. I left these alone from yesterday because I’m curious to see how ‘flat’ they are, and because I’ve never diddled with recently capped bottles and need an insurance policy.

- 11 clear flip-tops: same 2.5g from batch priming, plus one Fox’s carbonation drop. Two of these are recommended for a 500 ml bottle and together they weight in a smidge over 5g, so these flip-tops should be perfectly carbed.

- 10 non-metallic red crown caps: these also have 2.5g per bottle from yesterday, but to each I added one Cooper’s carbonation drop, aimed at 375ml and weighing in at 3.04g. This means the non-metallic red crown caps are technically over-carbed by 10% but I don’t expect it’ll make much difference – in truth I used the Cooper’s drops because I’d run out of Fox’s.

Looking back over the process of re-opening these I don’t think there’s very much to worry about. Each bottle was treated to a good dose of sanitiser before I popped the cap, and as soon as I did so I dropped in a carbonation drop and added a fresh, sanitised crown cap – or flipped shut the still wet flip-top. I did the flip-tops first and noticed that adding in the carbonation drop resulted in a fair bit of fizz, but because the flip-top was within reach I was able to cap it before anything boiled over. The first couple of crown caps I treated subsequently did eject some foam, but then I nailed the procedure and the rest were OK. No spinners or obviously leaky caps.

All 31 bottles were moved to the server room which is bouncing between 21 and 25 ℃ depending on the amount of sunshine that day. In around a week’s time I’ll put these out to the garage for conditioning.

#wisdom: ending with a positive, and I hear that cider isn’t too bothered about oxygen since it’s the hop oils in beer which cause oxidisation when exposed, so unless it’s a dry-hopped cider there’s nothing to worry about. Oh well, was fun playing with the beer gun all the same.

I’ve been fretting about this one since my first test at the end of February – what if they’re all ruined? Well, needn’t have feared. This lates sample has good clarity, a very malty, hazy flavour, and – above all – some carbonation!! Not quite enough for such a high ABV beer (in my opinion) but certainly enough to make it drinkable. To give it credit I’m not supposed to go near for another 10 days, but signs are good again.

Winding down for the evening with something sweet, and another 22a with absolutely no fizz. This time it’s a full-size 500 ml flip top bottle, and although there was a slight schnick when it was opened the nectar just sits in the glass like apple juice. Well, not exactly like apple juice, because it tastes a bit hoppy and alcoholic, but it’s not fizzy like it’s supposed to be.

Is it the bottles, or the primer? I wish I had a variety of vessels to compare, but something tells me I’m just sitting on a crate of flat flip-tops. Oh well. The landlady will like it since she hates fizz, but then again she hates sour too. More for me.

I wondered what LC stood for as I popped the cap off a Nog just now. Checking back on the bottling notes I see that LC means Loose Cap and I really should have tried twisting it to see if it was still loose before opening. Oh well, maybe next time. For what it’s worth the carbonation is just fine, and probably no different from the last one I tried. Maybe I’ll do a back-to-back comparison with the next LC bottle I find. Maybe I’ll forget. Again.

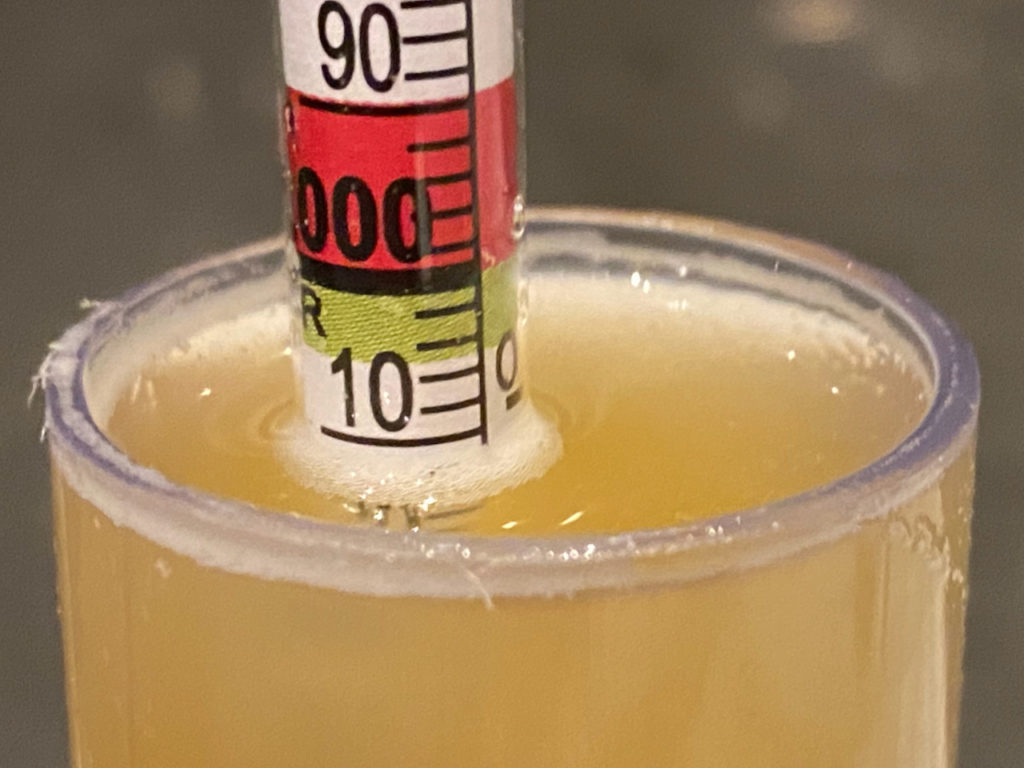

Gravity tested at 1.011 today which means she’s only dropped 1 point in two days. That’s technically not stable yet (still producing gas from 8 PSI to 10 in 30 – 40 minutes) but it’s been 4 days since I dry-hopped and that’s already too long for my liking. The brew tastes very nice indeed, with a velvety feel and some subtle hints of citrus. At 1.011 she comes in at 4.33% ABV, which is bang-on the expected 4.3% of its official draught sibling.

Ignoring the gravity, the delay in getting this cold-crashed was down to my new refrigerator not being delivered until yesterday, and it then had to stand half a day in order for the coolant to settle. Until I make a proper shelf for the Fermzilla she’ll have to rest on some paperbacks, which isn’t ideal since it’s not 100% level and I’m concerned about transferring uneven pressure to the vessel via the stand. Seems happy enough for now.

I started the refrigerator at 15:30 and 10 minutes later the thermometer inside was already showing 13 ℃ though obviously the vessel and its contents will take longer to get anywhere near that. In preparation for the increased CO2 absorption that comes with reduced temperature I’ve increased the pressure from 10 to 15 PSI, and will check in later to make sure she stays suitably high to prevent ingress of oxygen.

Speaking of carbonation, I’ve been thinking more about the effect of temperature on the level of fizz in the beer. Using the keg carbonation calculator I see that for 2.0 vols (upper end for a British Ale) at 2.0 ℃ I should set my regulator to 5.1 PSI. If I want the same level of carbonation at 20.0 ℃ I need to dial in 19.8 PSI, and I’ve been fermenting at 10 PSI until now in order to not stress the yeast. Can we therefore assume that in order to arrive at 2.0 vols / 2.0 ℃ I now need 20 PSI and not 15? I’ll definitely check in again later in order to add some more if it looks as though I need it – can always reduce pressure easily enough once the vessel temperature has reached its target.