Perfect until the end, I just drained the last of Yeti in order to free up a tap for my Opshaug Bure Gold. This Stout was truly epic right until the end and will be repeated very soon.

Yeti

| Ref | 2021-05 Yeti | Brewer | Pain & Patience |

|---|---|---|---|

| Style | Imperial Stout | Type | Beer, all-grain |

| Started | Wed 5th May 21 | Status | Archived, |

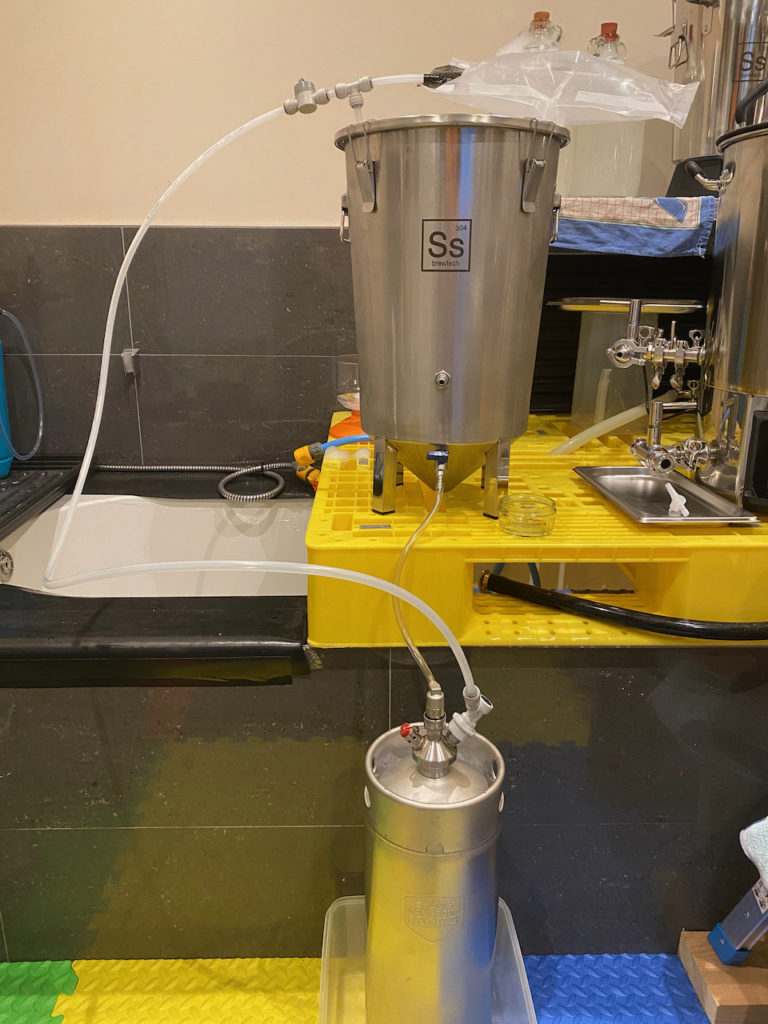

| Packaged | Wed 19th May 21 | Fermenter | SS 25 litre bucket |

| Handle | 2021-05 Yeti |

|---|---|

| Brewer | Pain & Patience |

| Style | Imperial Stout |

| Type | Beer, all-grain |

| Fermenter | SS 25 litre bucket |

| Status | Archived, ABV |

| Started | Wed 5th May 21 |

| Packaged | Wed 19th May 21 |

Having given one of these to Chris @ Bottle Monkey last week I wanted to try another one, just to see how much different it is from the draught version. 14 days of conditioning doesn’t sound like a lot for such a big beer and I was worried I’ve given away a dud, but thankfully all the flavour is there, as is the nose, and without any twang. The only downside is that there doesn’t seem to be the same level of carbonation. It’s not totally flat, and probably OK for a stout, but there’s just no head as you pour right until the very end, at which point you get a very thick slick of bubbles that barely covers the surface. Compare that to the velvety hat of creamy goodness you’ll find on the draught version and it appears to be a very different beer, even if they’re almost identical (below the surface) once left to settle. Maybe try for more carbonation next time?

With my 10 litre keg of Yeti now half empty I decided to transfer the remainder into a 5 litre keg so that I’d have the 10 litre plus another 5 litre keg available for Bure Gold (Kveik variant) when it’s ready. Poor planning on my part meant that I’ve ended up with 2 x 25 litres fermenting and only one vacant Corny keg, hence the scramble to free up as much as I can so that I don’t have to bottle a whole batch.

Those bottles of Yeti have been knocking around in the server room for 10 days now, so it’s about time they went outside where it’s marginally cooler. Can’t wait to try this one to see if it’s as good as the keg, but with such a high percentage big beer I think I’ll have to wait a couple of months before going anywhere near it.

I had a cheeky snifter just a couple of days ago and that’s when I decided that the keg pressure needed to be increased because this brew seemed flat. Having sat at 30 PSI for 3 days I’m pleased to say it’s now much, much better, and so I’ve taken it back to 15 PSI, which is going to be my new serving pressure unless I find there’s too much carbonation in the lighter ales.

Line Change

Also helping Yeti along is a change to the beer line. The tap I’m using was the last of three not to have a 5/16 section between the 3/8 sections needed at either end, and was still using 18 inches of too narrow 3/16 instead, which throttled the flow too much and didn’t give me the range of adjustment I needed on the tap’s flow control. For some reason this was more accentuated with the stout, and so I swapped out the narrow stuff for 5/16, thereby matching the other two taps. Now I have a good amount of control via the tap itself, and don’t need to rely on line length in order to get the right serving pressure, allowing me to have a slightly tidier kegerator.

Phenomenal Taste

Back to the brew, and I have to say this stout’s amazing. A deep and complex palate of malts, coffee and chocolate, velvety mouthfeel, and luxurious texture in the head, which now lasts all the way down. One half pint is probably enough to round off a school night and you certainly don’t want more than two of those – absolutely perfect for an imperial stout. On a side note, the bouquet is not 100% aligned with the taste. It contains all those coffee hints but also a very very slight suggestion of yeast, which in itself isn’t unpleasant, just unexpected. Ageing may remove this, but ageing is unlikely with something this good.

The only question in my mind is whether or not it actually needs the extra 2.5% that I was going for in the original recipe, or whether that would just turn it into one of those ridiculous bigger-is-always-better American approximations. Strength seems fine to me, taste is more than adequate. I do know I’ll be brewing something like this again soon and if I can refine my sparging technique I may be able to unlock those extra gravity points – will be interesting to see what it’s like then.

As Twisty Listy has just run out and freed up a line in the Kegerator I thought it’d be rude not to hook up Yeti and sample a small thimble. The result: great taste, almost no carbonation. To be fair I’m using my most aggressively throttled line, with just a small section of 3/8 at each end connected by about 3 feet of 3/16, but that should just result in less foam in the glass, not less carbonation altogether.

Brewfather reckons 10.6 PSI @ 5℃ for a week to get to 2.3 vols and she’s been sitting at approximately 11 PSI for 6 days, so in an effort to get her ready for the weekend I’ve turned off the other 2 kegs (both variants of Thirst Scratch) at the manifold and cranked Yeti up to 30 PSI. Let’s give it 12 hours.

Pretty straight forward kegging / bottling session today; filled the 10 litre MJ mini keg and 14 x 330 ml Steinie bottles with black caps. I left Bag Thing attached from cold-crashing as I moved the 25 litre SS Brewtech bucket out of the fridge and plumbed in a T-piece so that I could feed in CO2 from the keg as it filled and wouldn’t need to keep topping up the bag from my cylinder in order to prevent oxidation. The plastic bag acts as a great buffer in this respect and prevents any vacuum locks – not that I think O2 elimination is particularly important for this brew, but good practice all the same.

Once the keg was filled I plumbed in the Beer Gun and started to fill some Steinies, 4 at a time primed with 2.5 ml of Dextrose using a baking spoon and putting on a sanitised black crown cap as soon as the final blast of O2 was deployed. I’m sure I had about 18 litres in the fermenter and as 10 of those were kegged there should have been 24 Steinies to fill, but I only got 15 from what was left. To add insult to injury I had to chuck one of those away between capping and warm-conditioning as I noticed cracks in the upper neck of the bottle due to a manufacturing defect. Best not to risk an explosion or internal injuries from glass shards. Tough call though.

On a positive note I did recoup some yeast using a sterilised (boiling water) spoon and a sample tube which was from a batch originally purchased for Geocaching purposes. There was easily enough for another 1 lb honey jar in the bottom of the FV but I only grabbed enough for a small vial, reasoning that I’d probably use all of that to make a starter so there should be enough.

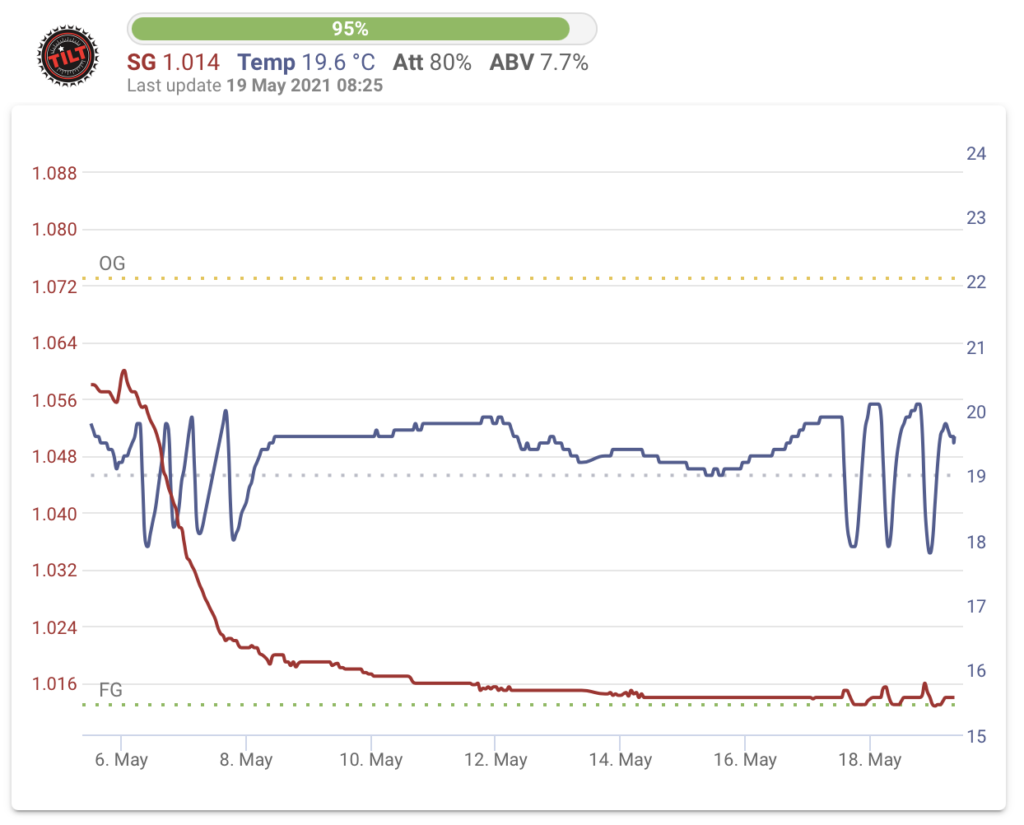

I’m unsure about bottling this today as planned because there are some weird things going on with the fermentation that I’ve not seen before.

The bulk of fermentation activity seems to have slowed around 9 May to the point where there isn’t enough heat being produced to trip the ferment fridge into action, and temperature has been fluctuating gently very near to room temperature, which for the most part was around 19℃.

Then something happened on 17 May which caused a sufficient temperature increase to trigger the cooler, which was set at 19℃ with a 1℃ ± threshold, so cooling starts at 20 and heating starts at 18℃. The gravity has also been bouncing up and down since then but I suspect that’s more due to the variations in temperature.

The question is, what’s causing the temperature to rise and trigger the cooler, three times in two days? There’s also some occasional airlock activity each time I open the door, as if fermentation is still underway. I can’t believe that’s the case after such a long period of stable gravity, and I don’t want to leave it too much longer, basically because I want to use my fridge for another brew, so I’m hoping that the worst-case scenario is over-carbonated beer and not an infection of some kind.

Having taken a gravity sample just now (and naturally a cheeky taste) I’m fairly confident there’s no infection – in fact it tastes bloomin’ lovely! Gravity looks to be 1.016 which makes for 7.5% ABV. Not quite the 9.7% I was hoping for, but still fairly respectable.

Instead of bottling it today I’m going to cold-crash it for a couple of days, just to see what I can convince to drop out. Bag Thing fitted, dials set to 4℃.

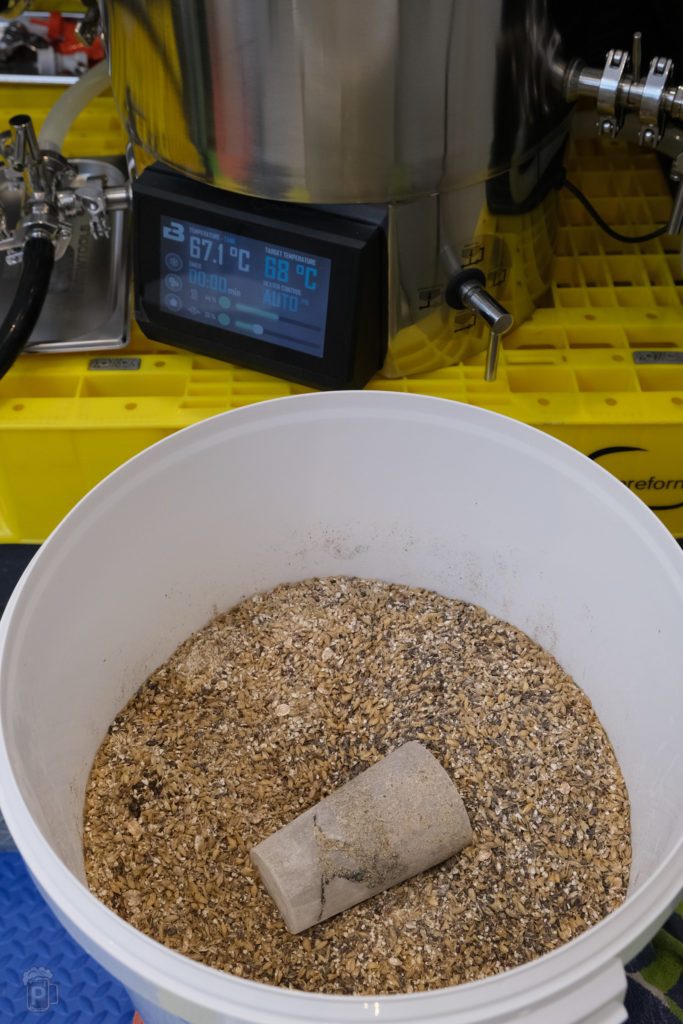

Another brew day, another first: Imperial Stout. This high ABV brew took a bit of jiggling to get it to fit my equipment profile and in hindsight I’m not sure that my take on the original Brewfather recipe was totally viable to begin with. Once I’d dialled in EBC values for locally available fermentables and applied my hardware profile I was right up to the limit of the B40s capacity, and that’s with no sparge water.

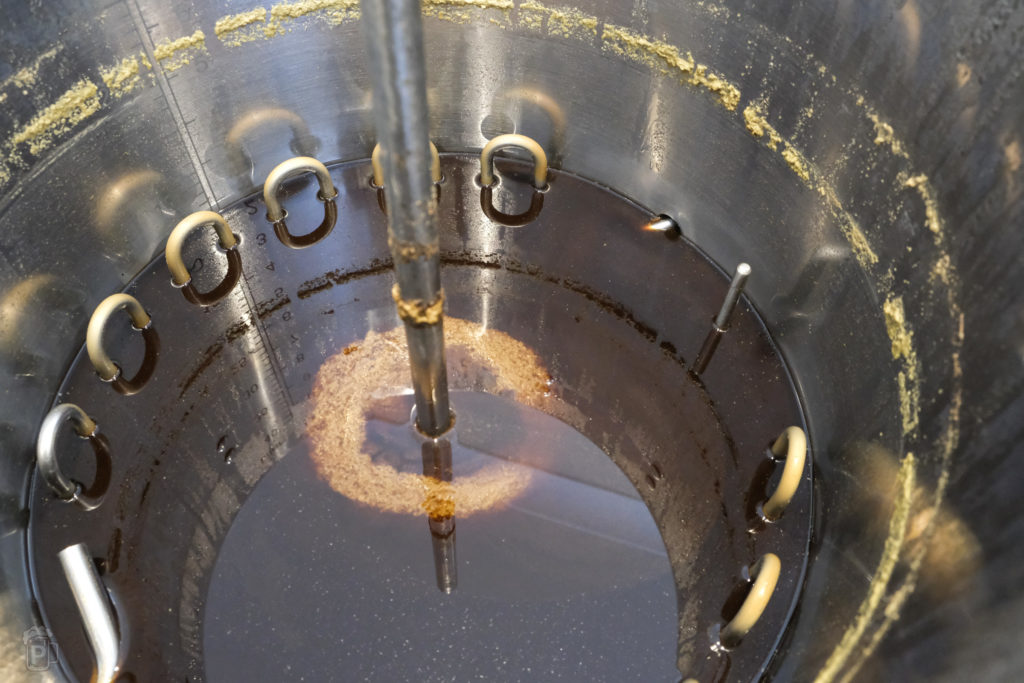

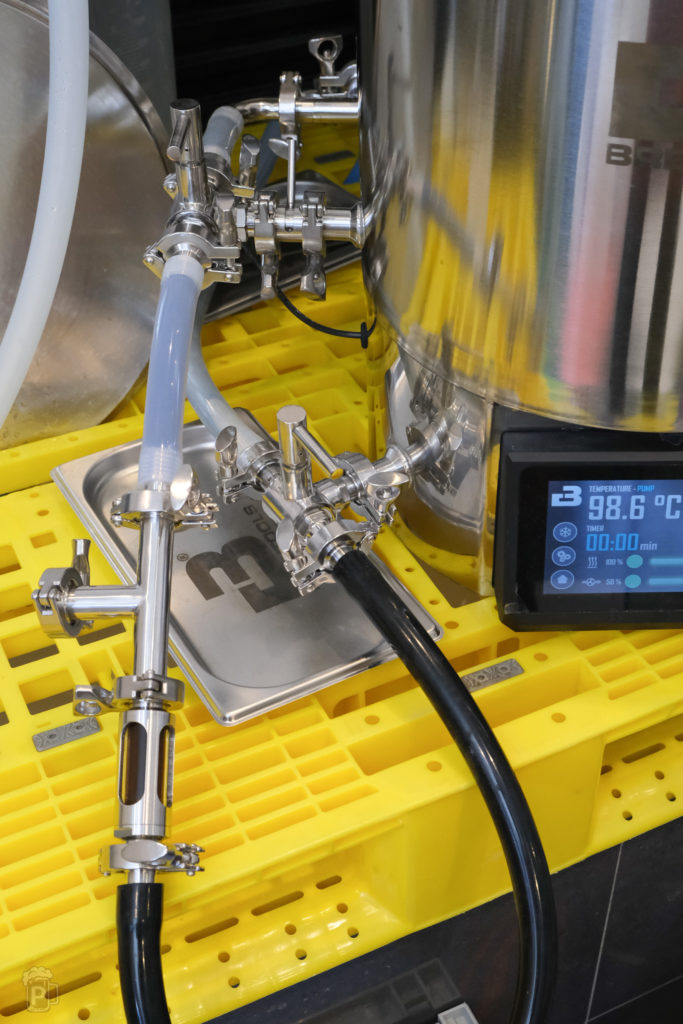

Still, it’s got to be worth a punt, and if anything the lack of sparging should be one less thing to worry about, right? Hmm. I don’t know why, but this brew day felt like hard work. For a start, the grain bill was 7.2kg and I had trouble getting it all into the malt pipe for the initial 20 minute mash rest. Consequently dough-in took a little bit longer, and once I was ready to start mashing there was no question of trying to achieve the usual fan of water from the sparge hat – the grain bed was just too high and there was no room to play with. Instead I set the pump for about 50% power and fed as much wort through the centre column as I could, backing it off when the level approached the holes where the handle connects to the malt pipe. I stirred every 10 – 15 minutes and that allowed a bit more worth through the grain bed, but as things slowed up again very quickly it was a case of constantly managing the balance between inside and outside the malt pipe.

The wort flowing out of the sparge hat was wonderfully dark and emitted a deep, rich aroma which permeated the brewery comprehensively, sticking around longer than that of previous brews. There was also quite a bit of detritus in the wort and I later regretted not fitting the Bouncer filter when transferring to FV – must get that sorted for the next run.

Once again I lost a lot of liquid during mashing and then yet more than planned during boil. Gravity was down too, so I need to sit down at some point and figure out if and where I went wrong with my hardware profile, or where I’m going wrong in my procedures. I’m writing this just over 24 hours from clean-up because I don’t want to leave it as long as last time, but still haven’t sat down and compared all of my measured values to those that Brewfather predicted, save for the all-important ABV, where I’ll be lucky to pull 8% against the predicted 9.6%. Not gonna be very imperial, this Stout!

I’m going to finally brew this imperial stout that I’ve been planning for a couple of weeks, and in the spirit of forever trying something new I’m preparing a yeast starter, using Brewfather for guidance. I’ve figured out that the quantity of yeast specified for most of the recipes on that platform actually implies creation of a starter, but it’s not immediately obvious unless you open up the yeast calculator and and hit ‘save starter’ at which point it tells you how much DME and water to add to the indicated yeast. If you calculate the amount without ‘save starter’ it’s the equivalent of pitching the yeast directly, and the amount required suddenly jumps up significantly.

Anyway, having tweaked the Yeti recipe to reflect my local fermentables’ values I turned my attention to yeast, and worked out that I’ll be needing 1.8 litres of water and 177g of DME if I want to stick with using just one sachet of M44. The calculator tells me this will result in 398 billion cells, which is 2 billion over target. My biggest Erlenmeyer flask is two litres so 1.8 doesn’t leave me with a lot of head room in the event that my yeast should go ballistic while being stirred overnight, but building for two sachets of M44 (which worked out as needed 1.3 litres and 128g DME) seemed a bit counter-productive to the whole idea of growing yeast in a starter, not to mention unnecessarily expensive: DME is cheap, yeast is not.

I decided to go for the single sachet approach, encouraged by the fact that Brewfather assumes an OG of 1.036 for DME and I have a feeling mine will be closer to 1.040, which is what some labs recommend as an ideal gravity for growing healthy yeast. Adding 100 ml to cover evaporation during the boil I filled a large saucepan to just below 2 litres and cranked up the heat, decanting exactly 177g of Muntons Light Spraymalt once we had a boil going. 10 minutes later we were done, and I’d obviously lost more than 100 ml because the pan’s internal scale read just over 1.5 litres, maybe 1.65 but certainly less than 1.75. Oh well – the mixture was transferred to my sanitised 2 litre Erlenmeyer flask and measured a smidge below 1.6 litres once I’d drawn off a sample for gravity measurement and started chilling in cool water.

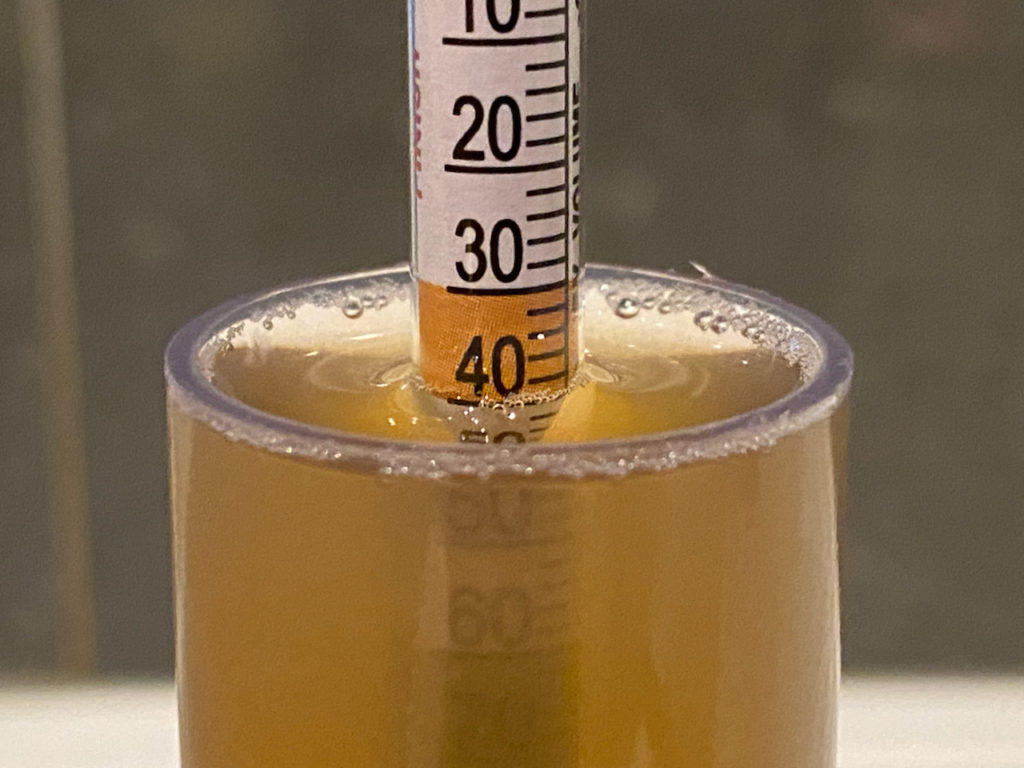

OG for my sample measured 1.040 at 364 ℃ which equates to 1.045 once you correct for temperature. Taking that value back to Brewfather I unticked the ‘calculate starter size’ box in order to allow me to input not only the gravity but also the amount of water, and I saw that with my one pack of M44 and 1.5 litres at 1.045 I’d be looking at around 408 billion cells – 11 billion over my target. That’s not too shabby at all; I’m not concerned about over-pitching 3 or 4%, 5 points over the ideal gravity shouldn’t stress the yeast too much, and I’ve got some extra head room in my flask for safety.

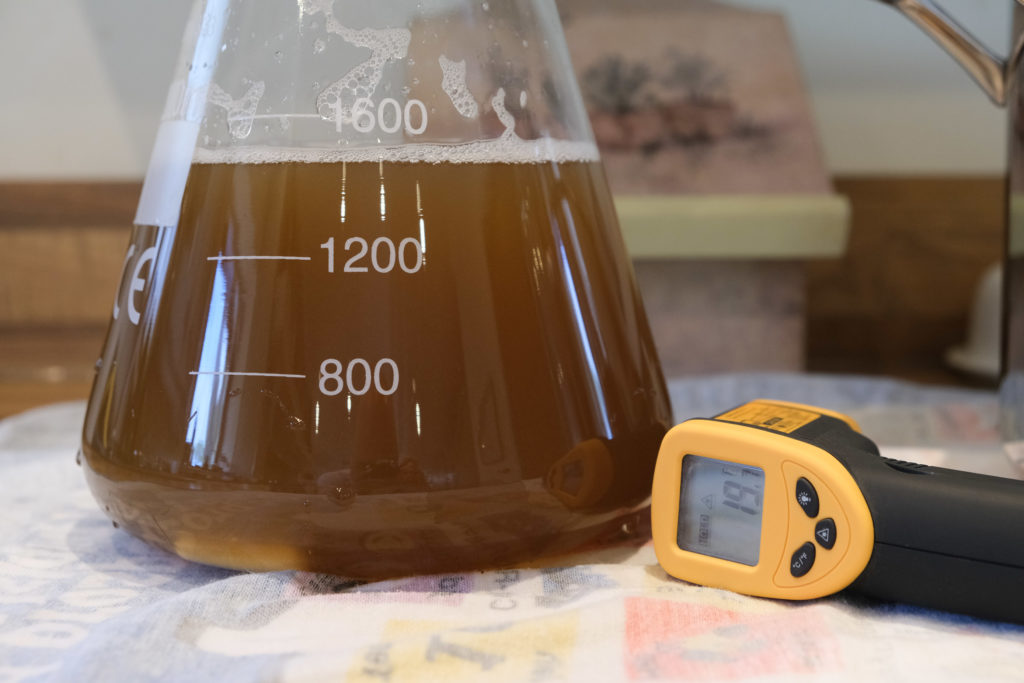

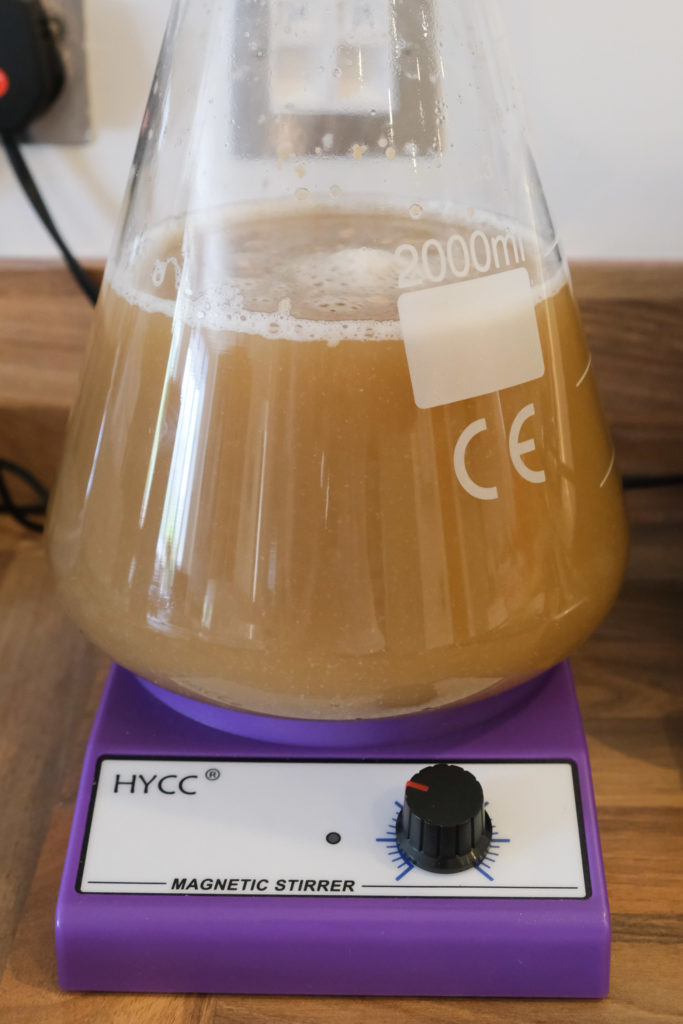

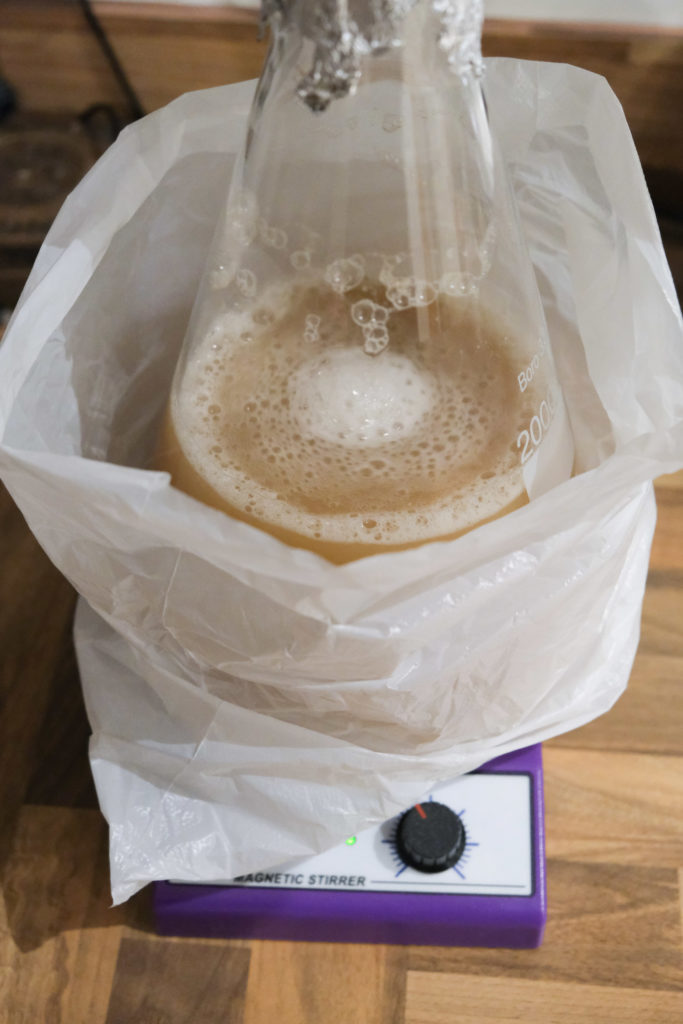

The stir bar was already in the flask from when that was sanitised by boiling a couple of inches of water (worked just fine on the halogen hob) so it was just a question of getting it down to temperature before pitching that M44. Not wanting to bet everything on borosilicate’s supposed resilience to thermal shock, I started off by putting the flask in a saucepan ¼ filled with cool water, then added cold water and left it to drop for 10 minutes before replacing the water with fresh, ice-cold water. Even so it was only 17.5 ℃ and therefore going to take ages to reach my target of 18, so I poured in two trays of ice cubes and checked in every couple of minutes using the infrared thermometer. Didn’t take long at all before I was at 18.1 ℃ so I threw in the yeast, refitted the tin foil lid, and gave it a good swirl before placing the flask on the stir plate at 13:17.

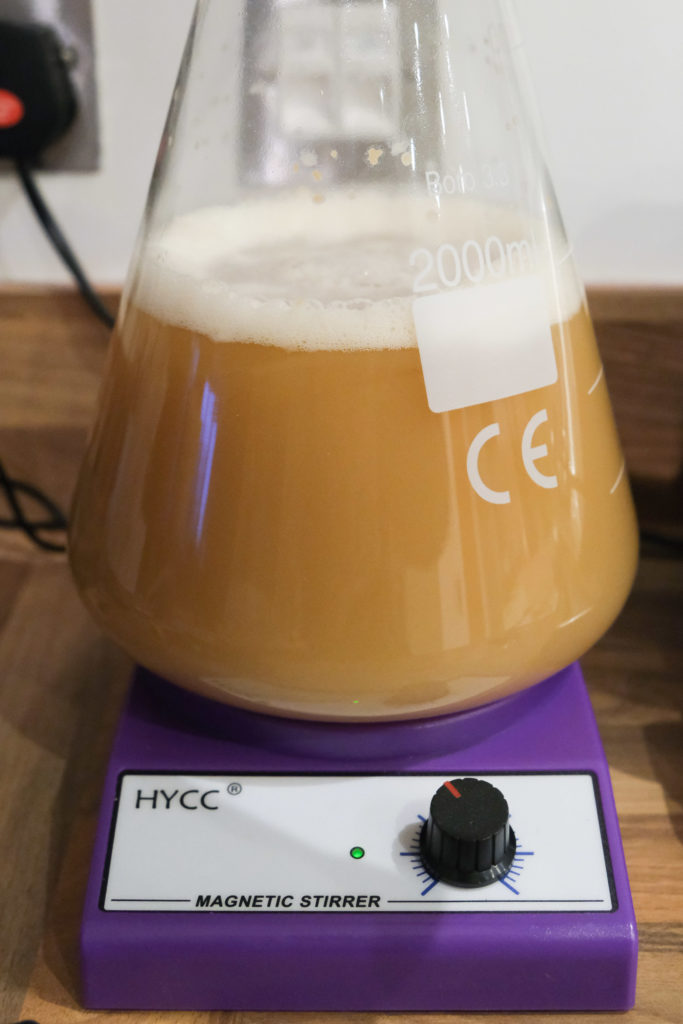

Over the next few hours my starter lightened considerably in colour and gained a layer of froth, which had stopped spinning when I checked in at 21:00. It also seemed as though the wort immediately below the foam was slightly darker, which I took to mean that the yeast was congregating in the lower part of the flask and a few mm of darker wort (spent?) had floated to the top. On giving the flask a good shake the colour evened out again and the foam head rose up quite dramatically, but soon settled down. On increasing the rate of spin to just below 50% I’m now seeing the foam mobile again. Only one last thing to do before turning in for the night: put the flask in a thin plastic bag. I don’t know what the Krausen’s going to get up to over the next few hours and I don’t want to find out if my stir plate is waterproof any more than I want to find out if our smoke alarms are loud enough.