Had a couple of these lately without carbonation. What’s going on? Maybe I should check if the caps can be spun before opening, as I can’t think of any other reason why these should be flat.

Honey Porter

| Ref | 2020-11 Honey Porter | Brewer | St. Peter's |

|---|---|---|---|

| Style | Honey Porter | Type | Beer, kit |

| Started | Sun 22nd Nov 20 | Status | Archived, |

| Packaged | Mon 14th Dec 20 | Fermenter | Plastic Bucket |

| Handle | 2020-11 Honey Porter |

|---|---|

| Brewer | St. Peter's |

| Style | Honey Porter |

| Type | Beer, kit |

| Fermenter | Plastic Bucket |

| Status | Archived, ABV |

| Started | Sun 22nd Nov 20 |

| Packaged | Mon 14th Dec 20 |

Cracked open our first bottle of this brew in Port St. Mary last night, and it was fantastic. Hardly any twang, just pleasant notes of honey and malt. Very easy to drink too – I’d still have two pints despite the sweetness before moving onto something else near the end of an evening. Very pleased with this.

2.5 cardboard boxes left over from bottle delivery, placed next to the Bromptons and registering around 6-8 ℃ most of the time.

When I took delivery of my first batch of 500 ml crown cap bottles I immediately started playing around and noticed that quite a lot of them allowed the caps to be spun under force, no matter how hard I leant on the capping tool. They didn’t twist too easily, and in most cases I’d have to use a tea towel to stop my hand from getting chewed up, but eventually most of them did spin and I began to worry that I might end up losing carbonation once I started using them in earnest. To that end I bottled Razorback in a variety of vessels; the purchased crown-caps, some recycled 500 ml bottles capped using the same tool (most of which didn’t spin) and a couple of clear 500 ml flip-tops for good measure.

I’ve since opened some of the brews that were bottled with those crown caps and purchased glass bottles, am pleased to report that I’ve had no flat beers at all, and those that I’ve tried to spin several weeks after bottling have been solid as a rock. So the demons are put to bed?

Almost. When I bottled Honey Porter and Wherry 36 hours ago I left them in the brewery with the heating cranked up at approximately 26 ℃ since the instructions just called for “somewhere warm” for two days. The cider which was also in there was moved out at the same time, so the only things in there are the Porter and Wherry. And it smells very strongly of CO2 just like it did when I added yeast to the latest batch of cider. Question is, can I attribute the smell to leaking crown caps on Wherry and / or Honey Porter, or am I just smelling the remnants of my biggest bottling session to date? For what it’s worth I’ve tried twisting some of the bottle caps from those two recently bottled batches and they all seem tight, despite most of them being slightly loose still just after bottling.

Making this entry in case I come to find some flat bottles amongst these two batches weeks down the road.

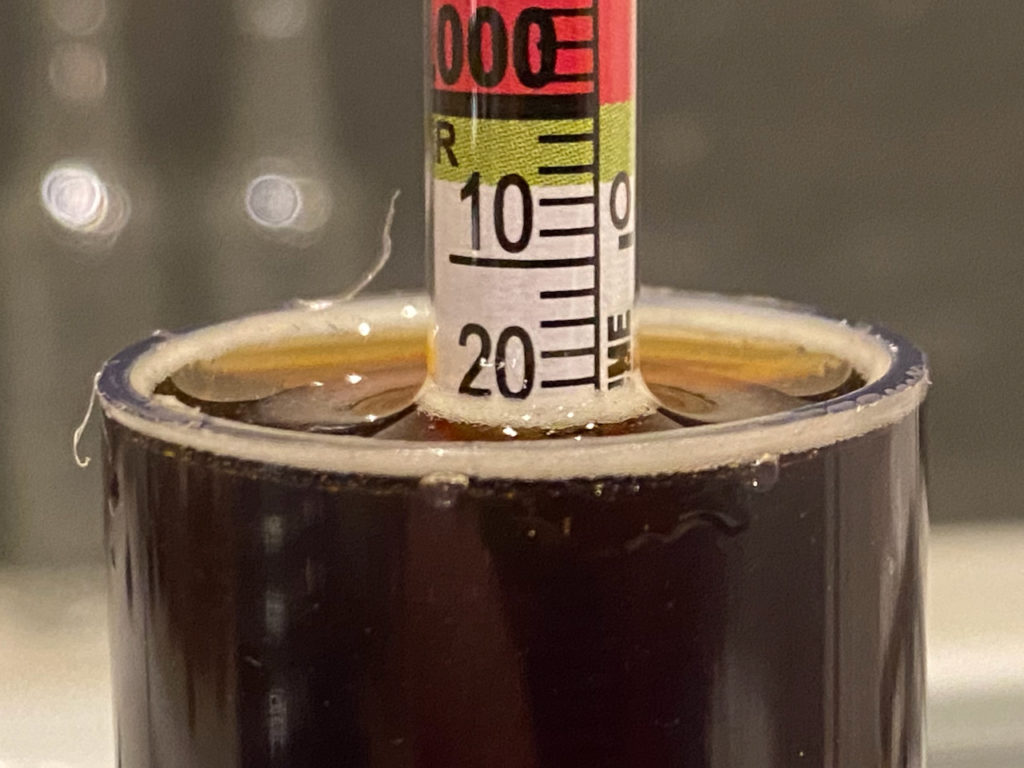

Stuffed this one into 38 purchased 500 ml brown crown-caps tonight, 13 days later than it should have been according to instructions, FG 1.014. Each bottle had 2x Fox’s Carbonation Drops, aimed at 500 ml total. Black crown caps used.

I’ll be moving this to the garage for conditioning on 17 December and it should be ready to taste on New Year’s Eve. Final ABV only around 4.07% versus advertised 4.5% but the taste is very good, so I’m not complaining.

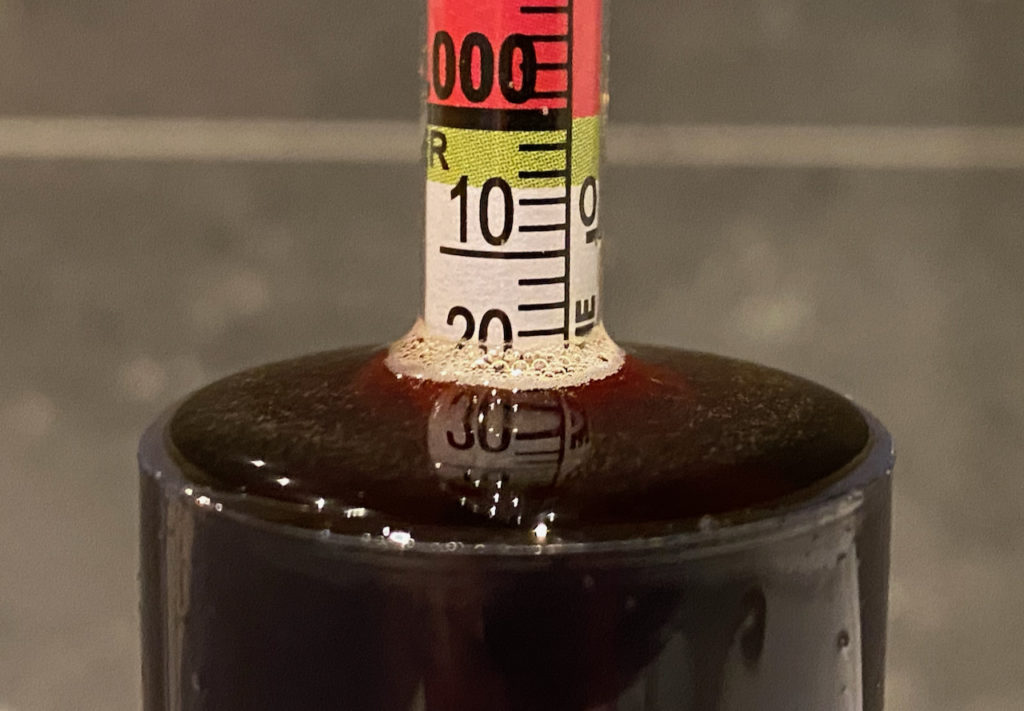

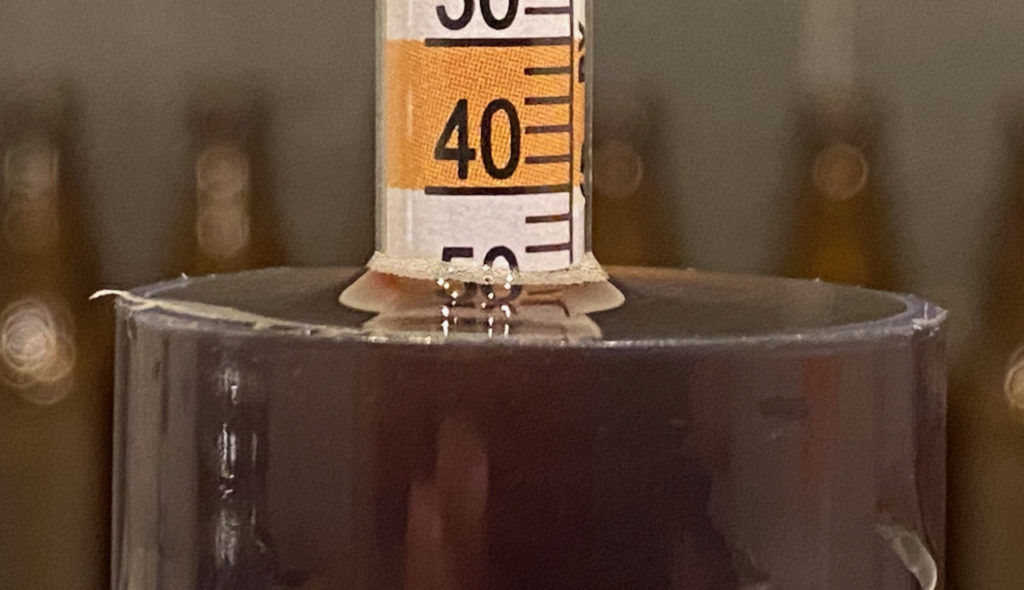

Looks like we’ve hit the magic 1.014 we need, and it tastes wonderful. There are still some signs of fermentation with occasional popping of the airlock, but I’m hoping that this won’t be a problem and am mindful of the increasing chances of off-flavours if it’s left much longer.

Getting this into bottles as soon as I finish sanitising them, either later tonight or tomorrow.

Tested the Honey Porter again just now and I’m seeing 1.015, which is near as damn it at the 1.014 we need to bottle. The final check will be to try again in 2 days and see where we are – if it’s not moved then it’s being bottled. Taste is just lovely, no twang at all and some deep, mellow notes of honey. Can’t wait for this one!

Not too much activity in the airlock of late, but gravity has dropped from 1.019 to 1.017 in the space of 5 days, making for about 3.68% ABV. I’m going to give this one just a little bit longer since we’re not at the target 1.014 and there are still signs of fermentation.

To be fair, in terms of taste and strength I’d be happy to bottle this now as it would make for a nice, easy drinking Porter in it’s own right, but I’m concerned about bottle bombs. Let’s see what another couple of days brings.

The Honey Porter was supposed to be bottled yesterday (according to the instructions) but there’s still some fermentation in evidence today, so I just took a gravity reading and will see where we are in two days from now.

Colour is lovely and dark, definitely smells of Porter too. Some signs of carbonation making SG reading tricky, had to give the hydrometer a couple of spins to make sure it wasn’t the small bubbles messing up the reading – never seen such high numbers this close to bottling. SG came in at 1.019 giving approximately 3.41% against a claimed 4.5% and since we’re looking for 1.014 or below I don’t think it’s quite ready yet.

At least it tastes lovely, plenty of honey notes and only slightly raw – a pint of this wouldn’t be too bad at all right now! This will be lovely when it’s done.

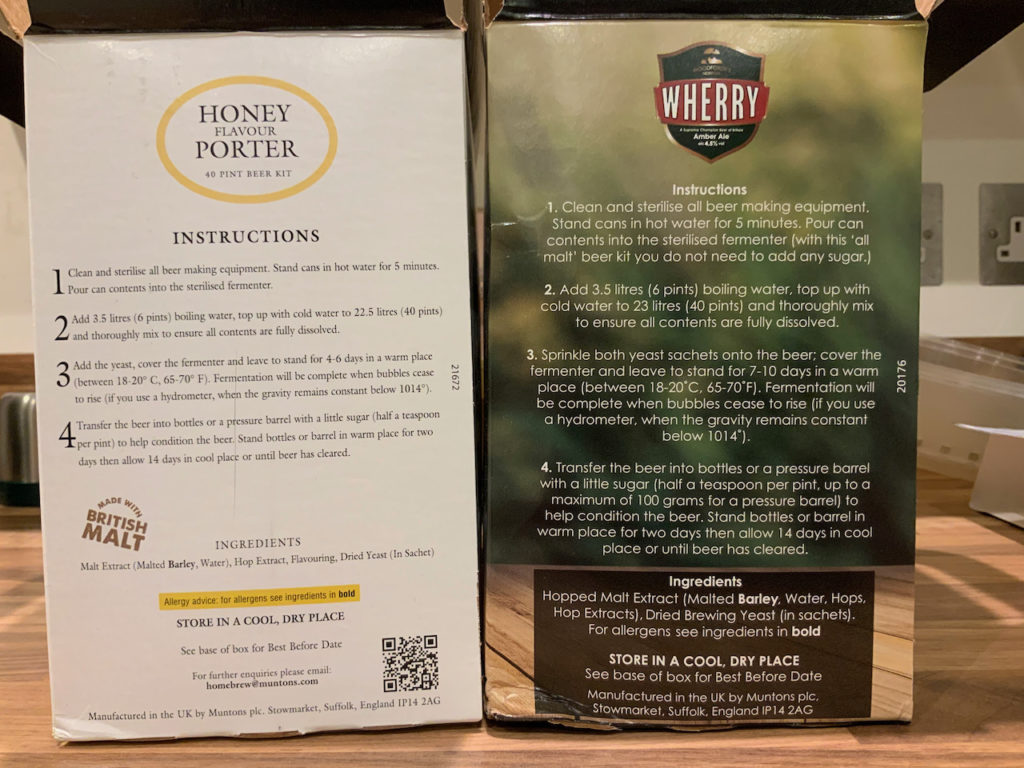

Both the Honey Porter and Wherry have been bubbling nicely two days into primary, and I’ve been gradually trying to reduce the temperature since they want to be kept between 18 and 20 ℃, finding that the FVs tend to hit 18.5 when the room temperature is 17 to 18. Bubbling has slowed a little over the past few days, but there’s still enough going on with both that I needn’t worry about bottling the Porter yet tomorrow. Will take a SG reading instead and revisit in another two days.

It’s been 12 hours since Wherry and Honey Porter were committed to FV, and they’re both bubbling away slowly, maybe once every 5 minutes. Both were slightly faster within an hour of the yeast being sprinkled onto the brews 40 minutes after adding the cold water, around 24.8 ℃, and that seems to have slowed up since then. Right now both buckets are still at 22.5 ℃ despite the office being 20 ℃ – not dropping quick enough. I hope the yeast hasn’t been damaged as a result, though if it were that sensitive to temperature that would surely have been mentioned in the instructions?

Been meaning to kick this one off for a while now but the brewery is slightly higher in temperature than this (and Wherry’s) preferred range of 18-20 ℃, so in the end I decided to keep it in the office. Initial ingredients:

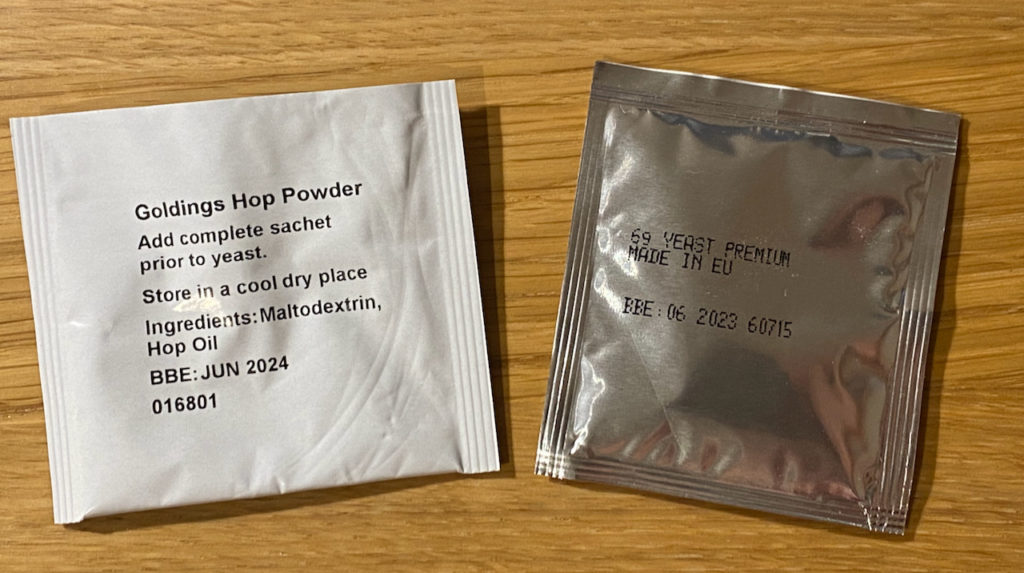

- 3 kg malt extract

- Small sachet (10 g ?) Goldings Hop Powder

- Small sachet (10g ?) 69 Yeast Premium

- Water to 22.5 litre mark

Usual story of emptying the cans into the bucket, adding hot water, and mixing before topping up with cold. I added the hop powder halfway through topping up with cold, getting it nicely mixed into the brew.

Although the instructions didn’t say anything about letting it cool before adding the yeast, I allowed it to get just below 25 ℃ before pitching. OG = 1.045.