Just pulled the last pint of this one, coincidentally on the evening before another brew day; Jackknife Barber. What can I say? Brilliant. I’m very pleased at the haze, right to the end, and the impressive retention of hop aroma and body, almost 6 weeks in the keg. Net time around I may well try under-pitching more aggressively with just a quarter pack of Voss (used half a pack on this one) in order to eek out yet more of that delicious citrus flavour. To be repeated!

Geronimo

| Ref | 2022-11 Geronimo | Brewer | Pain & Patience |

|---|---|---|---|

| Style | New England IPA | Type | Beer, all-grain |

| Started | Tue 6th Dec 22 | Status | Archived |

| Packaged | Tue 13th Dec 22 | Fermenter | Fermzilla |

| Handle | 2022-11 Geronimo |

|---|---|

| Brewer | Pain & Patience |

| Style | New England IPA |

| Type | Beer, all-grain |

| Fermenter | Fermzilla |

| Status | Archived |

| Started | Tue 6th Dec 22 |

| Packaged | Tue 13th Dec 22 |

Geronimo and Yeti Hit the Road

We’re across with family for Christmas, and although I toyed with the idea of taking a couple of party kegs with me I decided against it in the end; it’s a short visit, I’ve only one decent dispense tap, and I still haven’t sourced (let alone tested) a Sodastream bottle for mobile use. All of which meant that I could put it off no longer, it was time to finally break out the counter-pressure bottle filler I thought I badly needed when I started out kegging.

It was actually fairly easy to rig up, with the most difficult part being a lack of compatible ¼” Duotight connectors, but that was soon overcome with a section of slightly smaller diameter beer line and a heat gun.

Purging and filling the bottles too was fairly easy. I started with Geronimo, which had been sitting at 15 PSI / 4℃ for 6 days by this point. The first bottle filled with just half an inch of foam thanks to some bubbles in the line, but subsequent bottles had no head at all. Maybe I should have tested the brew first – was it still not quite ready?

After 7 bottles were done I switched over to sanitiser and flushed the lines with about a litres, before switching to Yeti and again flushing through about half a litre. For this one I used 330 ml clear lager bottles, and these didn’t want to stay upright as readily as Geronimo’s 500 ml standard brown flasks. They were also a tad shorter, which meant the counter-pressure filler’s (CPF henceforth) bung had to be carefully moved to the extreme end of travel and monitored for blow-out. The carbonation was a little higher on Yeti, and combined with the narrower bottles I found that foam made its way more readily up the neck than with Geronimo. It’s difficult when you’ve only got one gas line running into the Kegerator…

All-in I had a positive experience with the CPF. It was a bit messy in places and took a few minutes to clean and sanitise, but on the whole I’d use it again, though perhaps for bigger batches. One thing I will definitely do differently next time is to rig up some kind of CPF suspender, because it’s quite a big old lump to delicately balance on an empty bottle while capping the one you’ve just filled. Live and learn.

Geronimo III: First Taste

Great hop flavour, maybe 5% too bitter for the style. Aroma could do with being more floral too. Mouthfeel isn’t quite there yet and neither is carbonation, so I’ll give it another 2 days at 15 PSI and then take it down to 10 since I’ll be away over the festive period. Generally OK.

Quite a bit of hop debris this time and also a crazy amount of spent yeast, given that I only pitched half a packet. At any rate, the collection jar was solid with grey gunk and the sides of the FV were covered in green, so I guess the cold-crashing worked on both counts.

Transfer was into fully purged keg using purged lines for gravity-fed closed loop. The filter on the floating dip-tube worked OK but I’m going to move the weight onto the end of the filter housing, and maybe shorten the tube a little so that it doesn’t snag on the sides near the bottom, Realistically there wasn’t much left behind in the FV amongst all that trub, but I did have to coax the dip tube along towards the end by tilting the vessel.

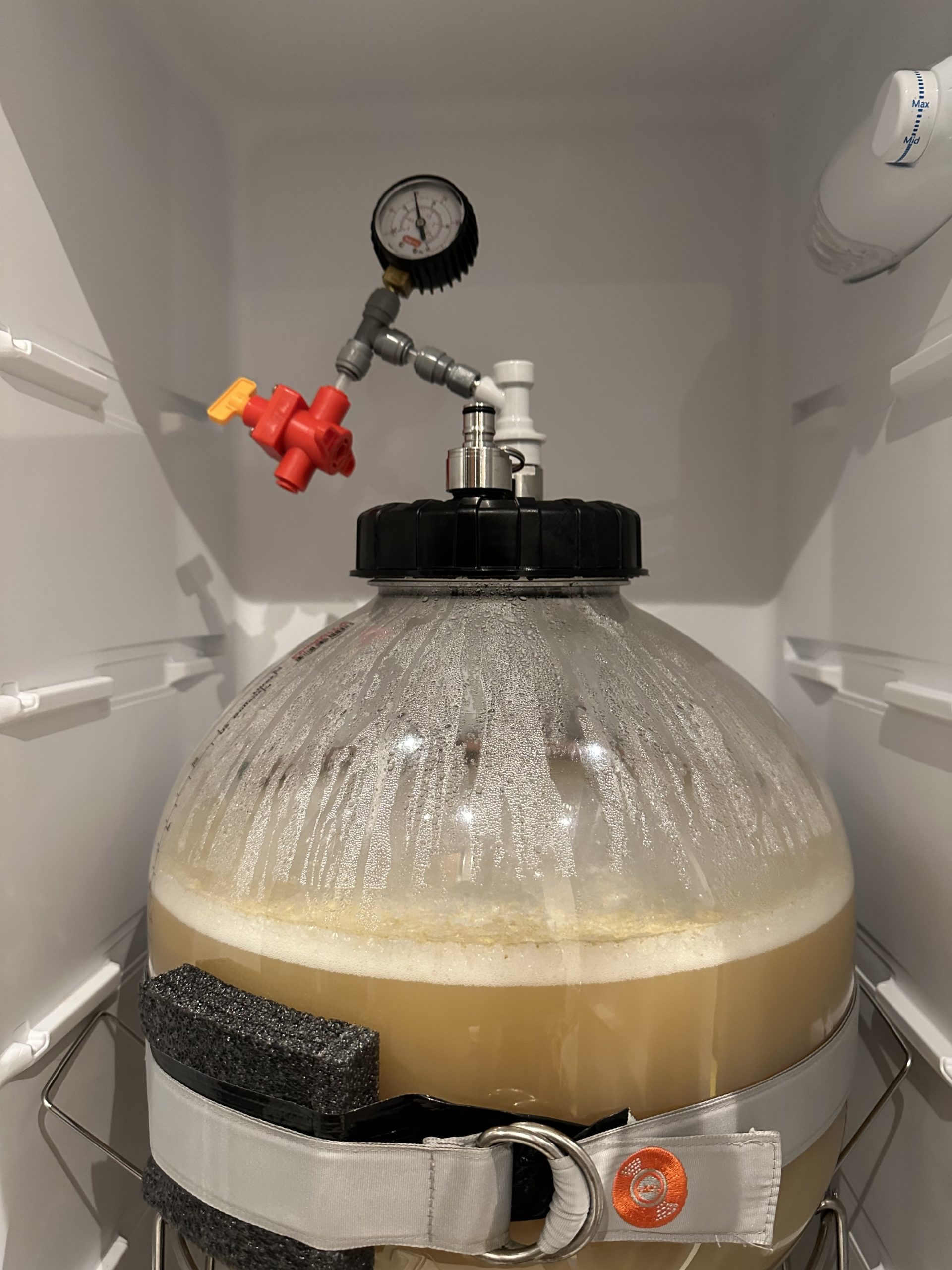

With a starting temperature of 34℃ I don’t want to place the chiller under too much strain, so I’ve left the fridge door and the brewery window open for a day now in order to drop some of the heat naturally. Pressure has been allowed to build to 15 PSI in preparation for chilling, all’s going well.

Throwing in those hops has restarted fermentation and I’ve dialled the spunding valve up to 15 PSI, where it’s hissing gently. This is great; we’re displacing introduced oxygen with CO2 and storing some pressure to prevent suck-in during subsequent cold crashing.

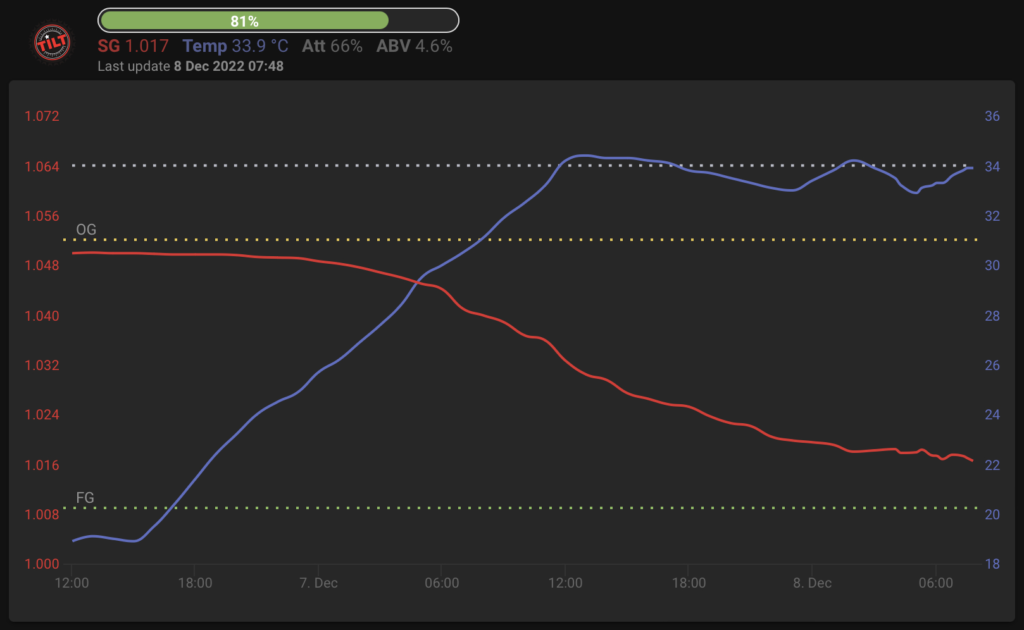

Also good is an apparent correction to the gravity readings. Presumably there was some Krausen buildup on the Tilt which caused it to report a higher value, but de-pressurising the vessel ahead of dry-hopping must have given it a knock and we’re now reading a gravity value that’s much closer to the expected FG. It’s not uncommon to get a bit of a jump from the Tilt when depressurising, so I deleted the most recent two readings as soon as the lid was back on, but the following readings were also at the new value so I’m confident that it’s reporting correctly, at least for ‘light’ beers such as Geronimo.

0800, Thu 8 Dec

The airlock has been hissing loudly since fermentation started about 14 – 18 hours after pitching, and although the graph hasn’t flattened out completely I see that the surface of the brew is completely clear, and all yeast has disappeared apart from the usual remnants of dried Krausen around the rim.

So what to do now? I’d like the finishing hops to go in there before fermentation is 100% done so that we get a little bit of CO2 driving out any of the inevitably introduced oxygen, and with that curve not levelled out yet (at 66% attenuation, ostensibly) I think we have another day or two, but where’s the yeast? Was I right to under-pitch. Maybe I’ll wait until this afternoon before making a decision.

16:00, Thu 8 Dec

I checked the fermentation curve again this afternoon and it does indeed appear to have flat-lined, so I threw in the finishing hops and deployed the sanitised floating dip-tube. No purging or undue ceremony, hopefully there’s still a bit of activity in there to drive out the oxygen that I’ve undoubtedly introduced.

A good brew day without incident, the only unexpected factor being that I was supposed to be doing a SMaSH with a friend today but that was cancelled, so Geronimo it was. Not having time to make a starter and with a whole bag of OYL-061 Voss in the fridge I decided to try under-pitching and a warm ferment in order to get some of the supposedly fantastic citrus flavours creeping out.

We’ll see how that goes, but for now I’m pleased to report that despite a slow start I’m seeing strong fermentation since the small hours of this morning (approx 14 hours after pitching) and I see that the spunding valve was set way too high at 15 PSI. I’m dialling that back to 7 PSI because I want the esters to have a chance, at least until I dry-hop at which point I’ll increase back to 15 PSI to give me a safety net for cold-crashing.

Continue reading