Keg Business as Normal

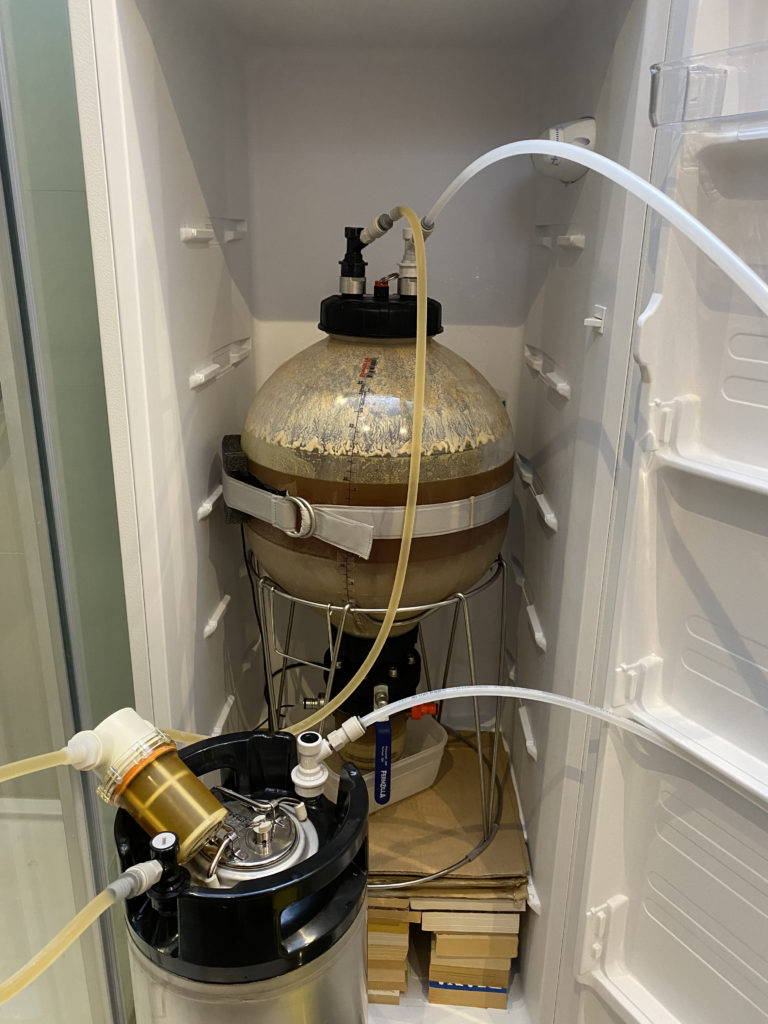

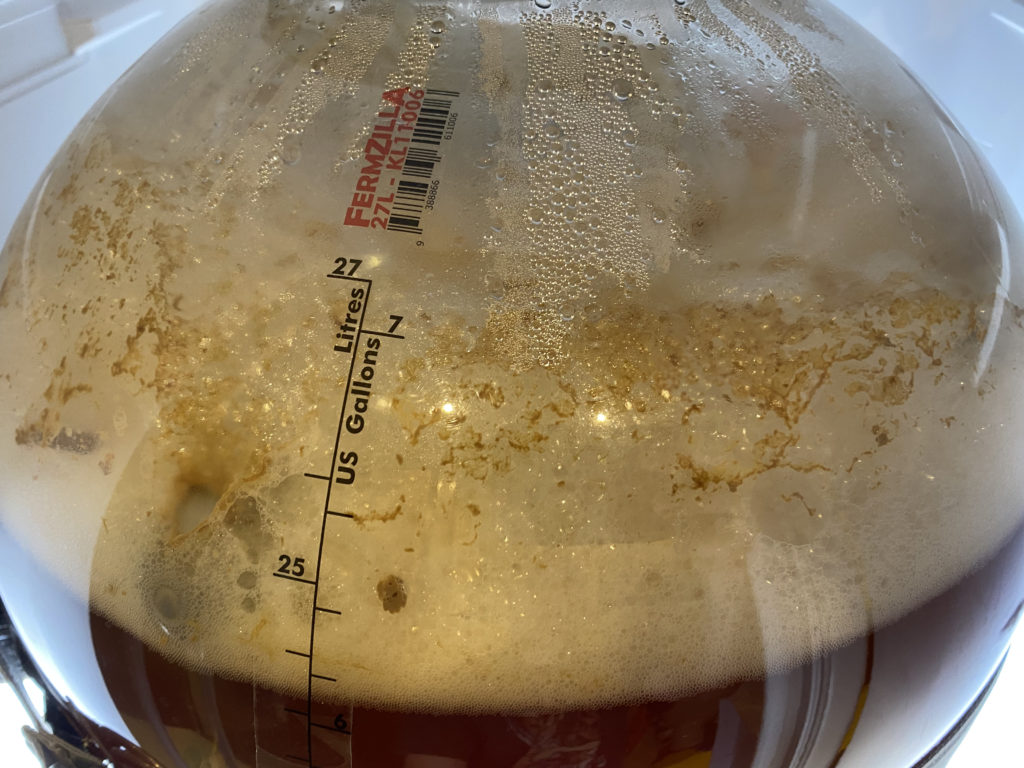

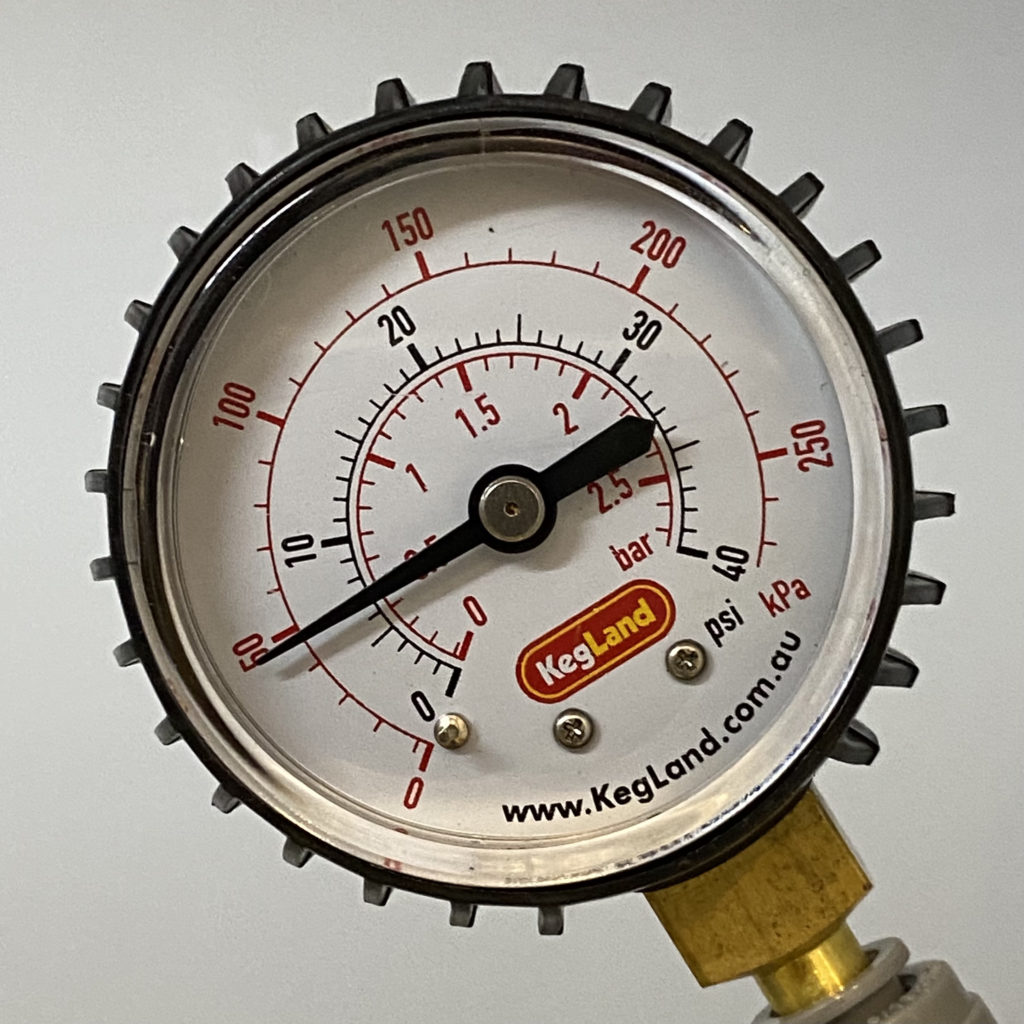

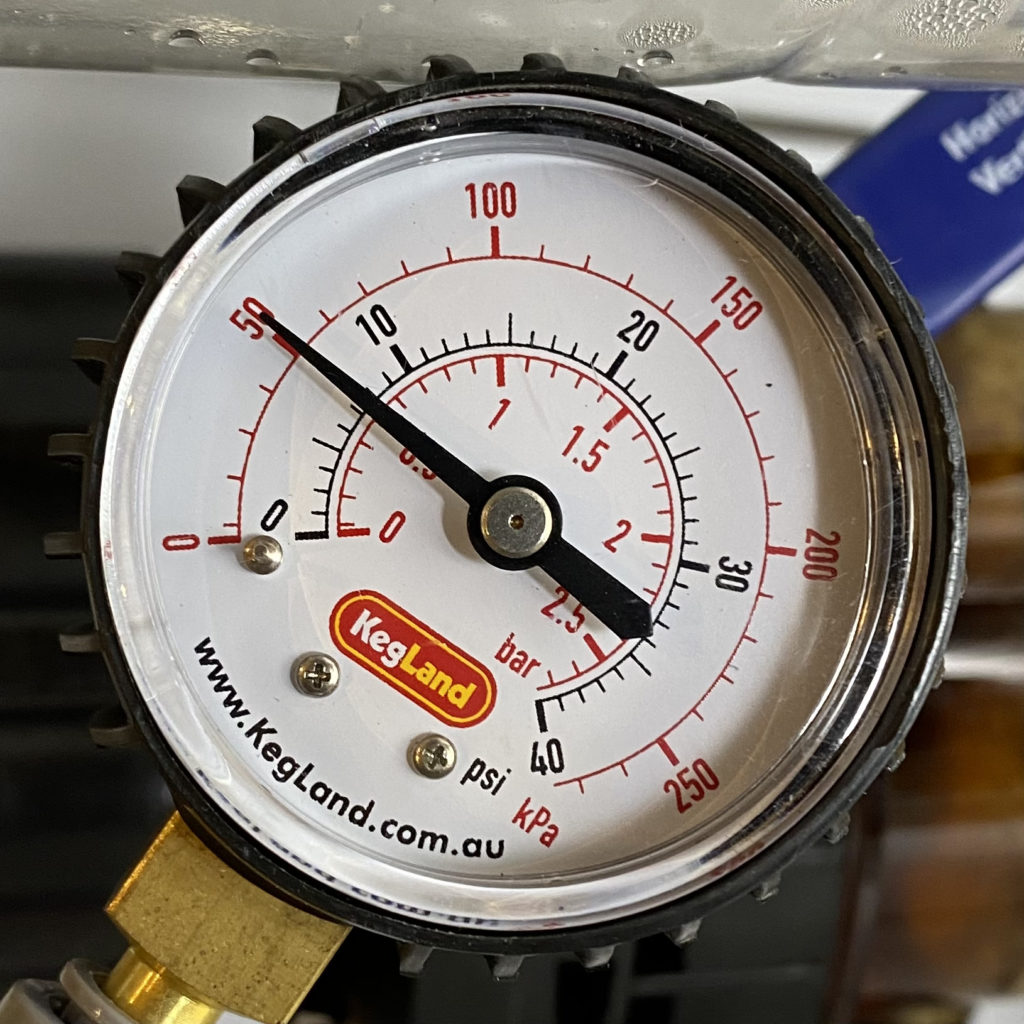

Standard story here with no drama; began as a closed loop pressure transfer at around 5 PSI (had dropped from 15 to 5 during cold-crashing) and filling a 19 litre Cornelius keg via floating dip tube to liquid-out post. After a while I grew bored with the trickle of beer from one vessel to the other so I junked the gas line and rigged the Fermzilla straight to my CO2 cylinder while popping the PRV on the keg now and then.

Bottling Carbonated Beer

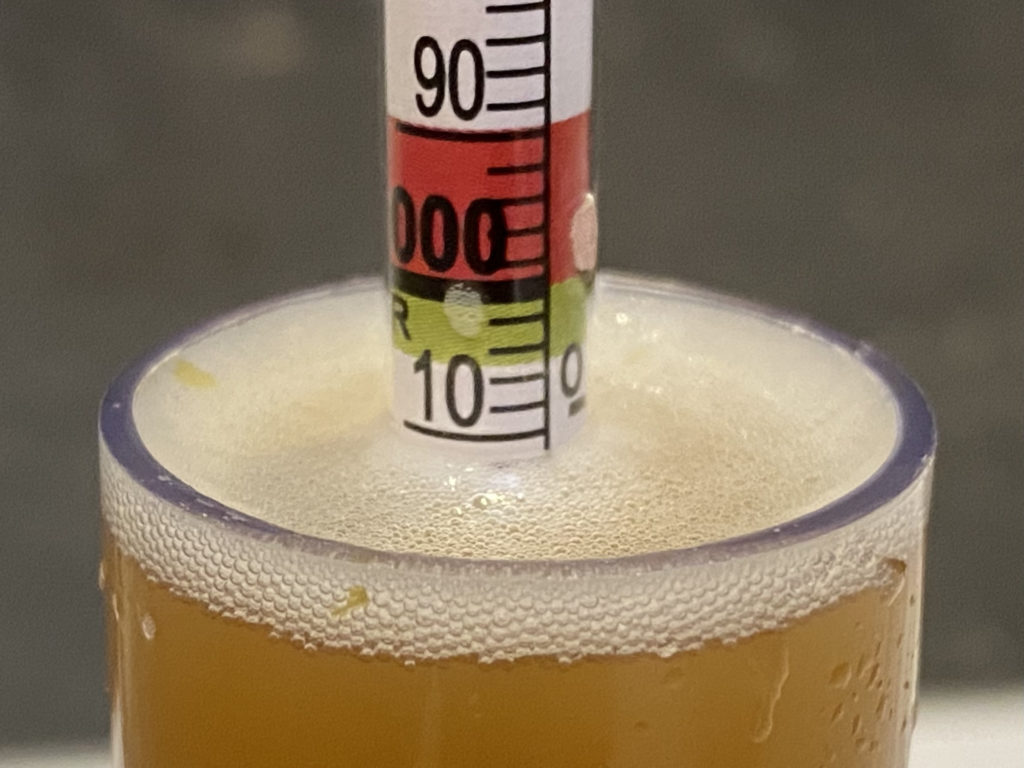

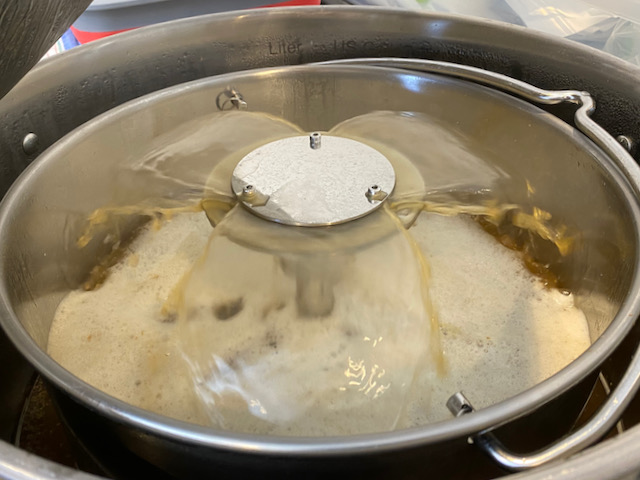

There seemed to be between 23 and 24 litres in the Fermzilla, so having filled a 19 litre Corny keg I decided to try something I’ve been thinking about over the past couple of weeks: getting the remains into some bottles without making an almighty mess. Turns out that it’s not too hard at all, provided you have some threaded PET plastic bottles and a spare carbonation cap. Simply pop the liquid disconnect off the Corny keg once its full, and whack it onto a carbonation cap fitted to a plastic bottle. Originally I wanted to use the plastic T-piece on my bottles because that would allow me to have dedicated liquid and gas posts – just like a keg – but I was down to my last carbonation cap and therefore had to use it for liquid, venting out gas to keep the flow going by unscrewing the cap a few turns.

It worked pretty well, and although I pre-ressurised my first bottle so as to match the keg and minimise foaming via the dip tube on the bottom of the cap, by my second bottle I’d forgotten to do this and it didn’t seem to make any tangible difference. In the end I filled two and a half 1 litre bottles with practically no mess, unlike those tap-mounted counter pressure fillers you see now and then. The only downside is that when removing the carbonation cap after filling a bottle it effectively vents the headspace to atmosphere before the plastic cap is fitted, which may affect carbonation, and the exposure to oxygen may lead to oxidation too. Don’t care – with no way to carbonate these plastic bottles any further I’ll just have to drink them fresh while the keg matures, which is something I can live with.

Closing Thoughts / Wisdom

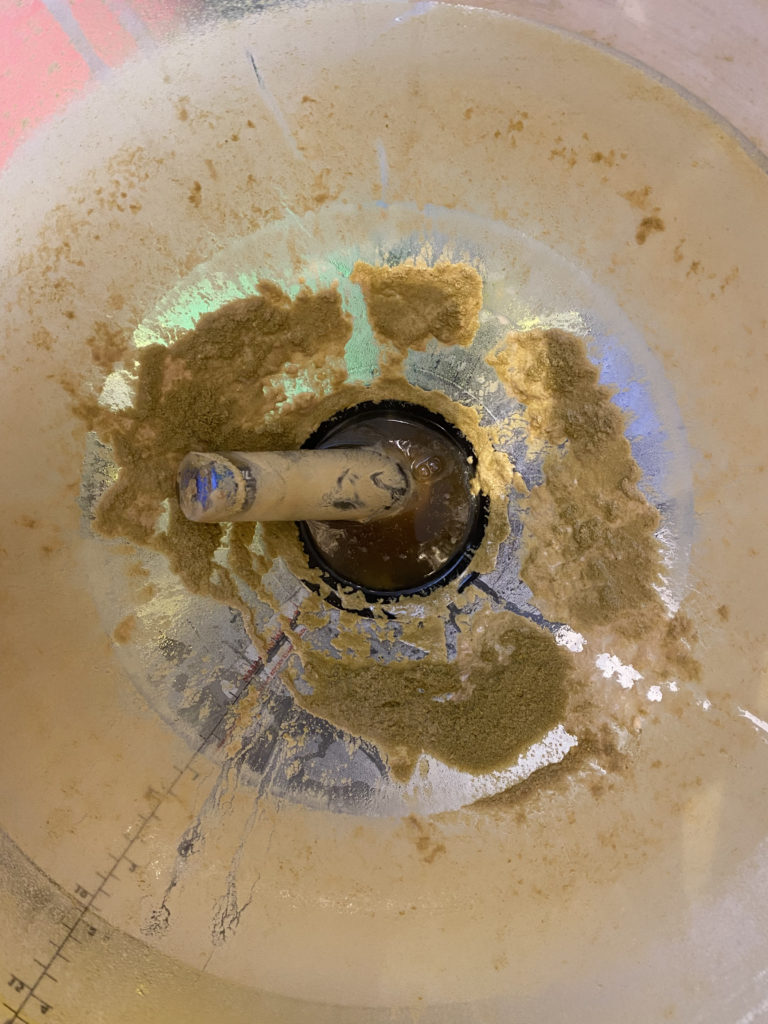

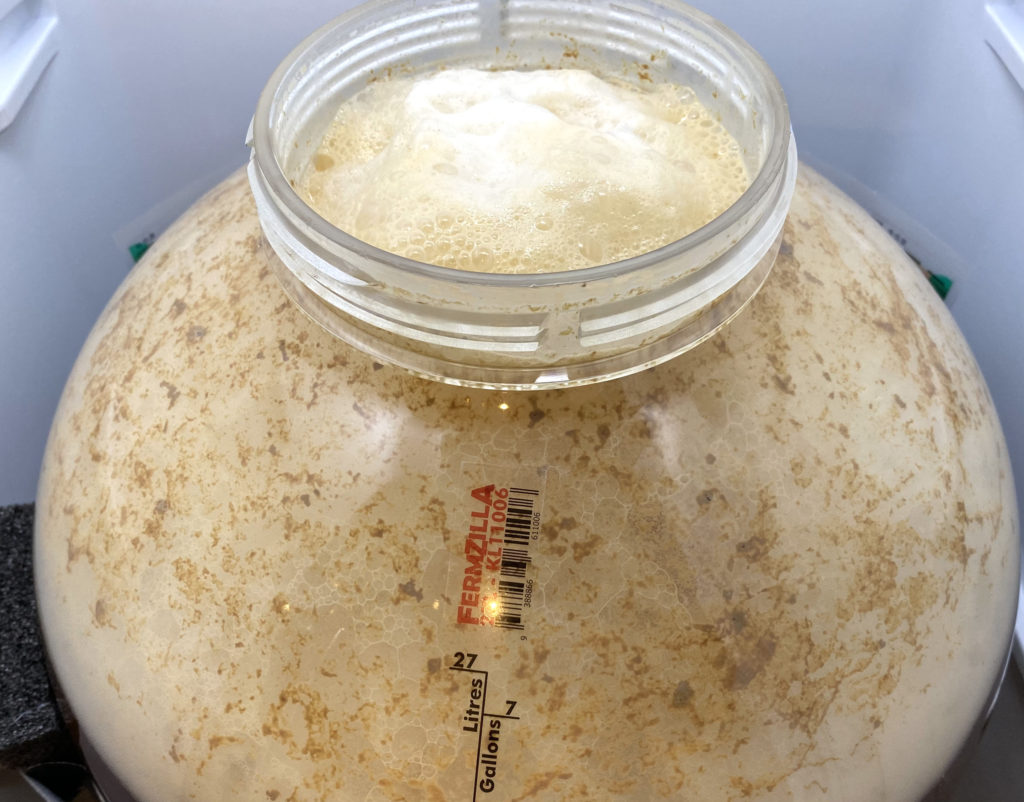

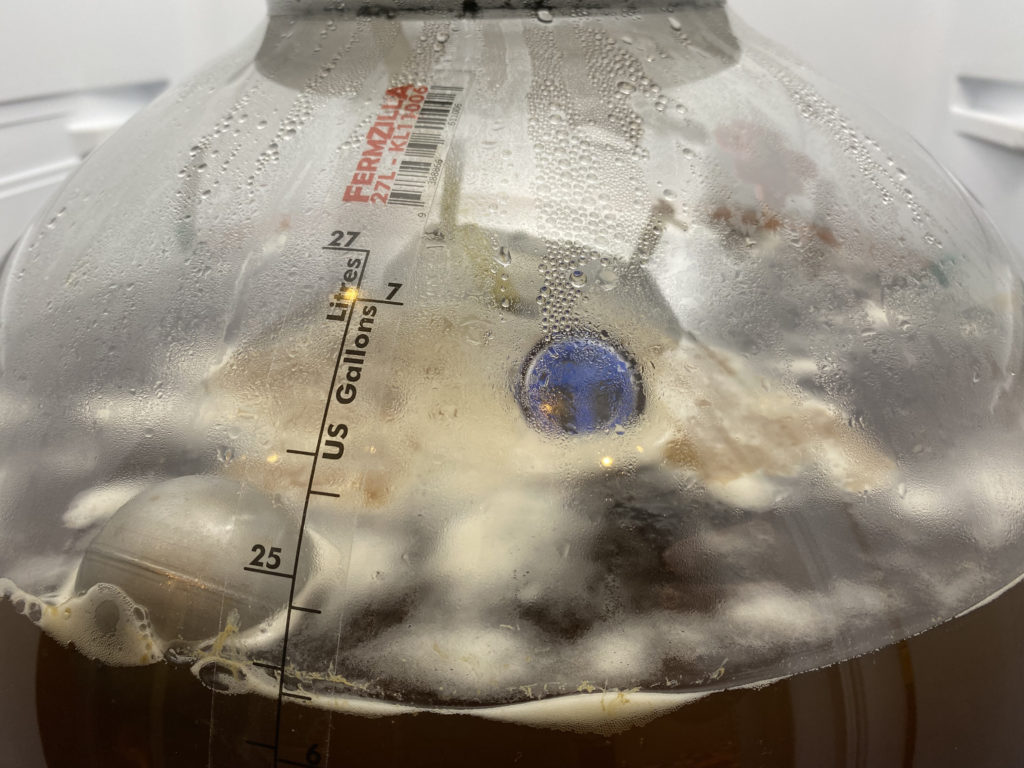

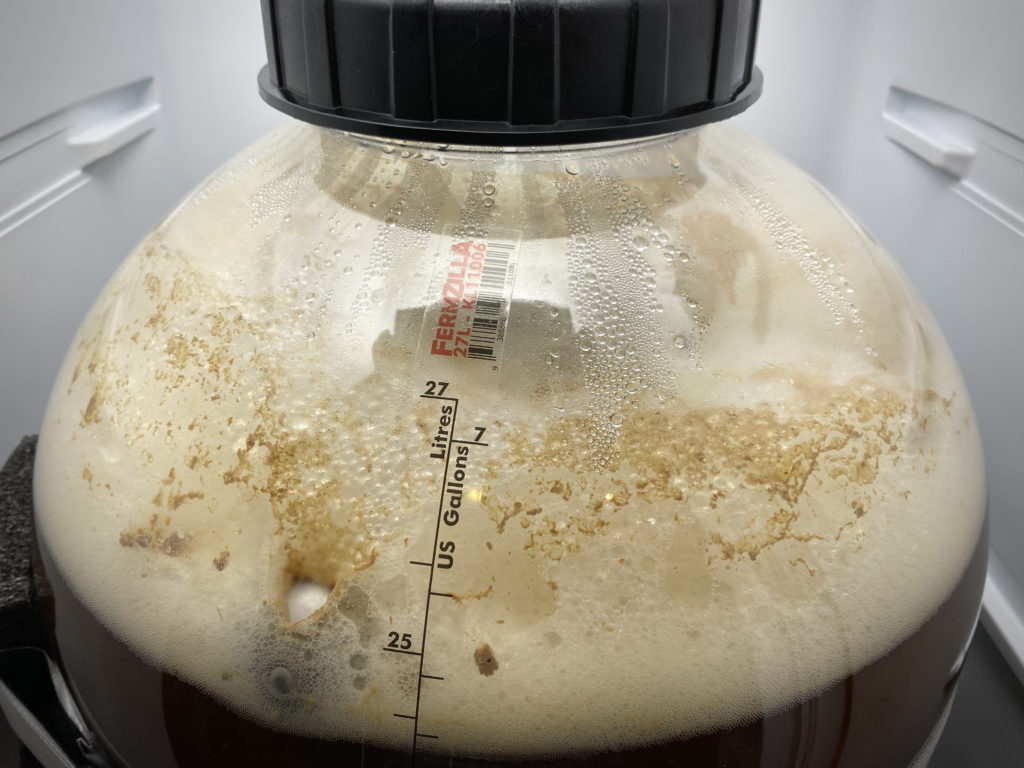

- The distribution of finishing hops this time around has been much better than during Twisty Listy. I don’t know if this is due to me being a bit more violent when releasing the butterfly valve during dry-hopping and having everything slosh around, or if it’s a consequence of using Kveik yeast which led to a resurgence of ‘boiling’ fermentation once the finishing hops were added 9 days ago. I do know that the presence of hops is very prevalent on the palate and in the nose, something I’m very pleased about, especially with just 50g added. No worries here at all.

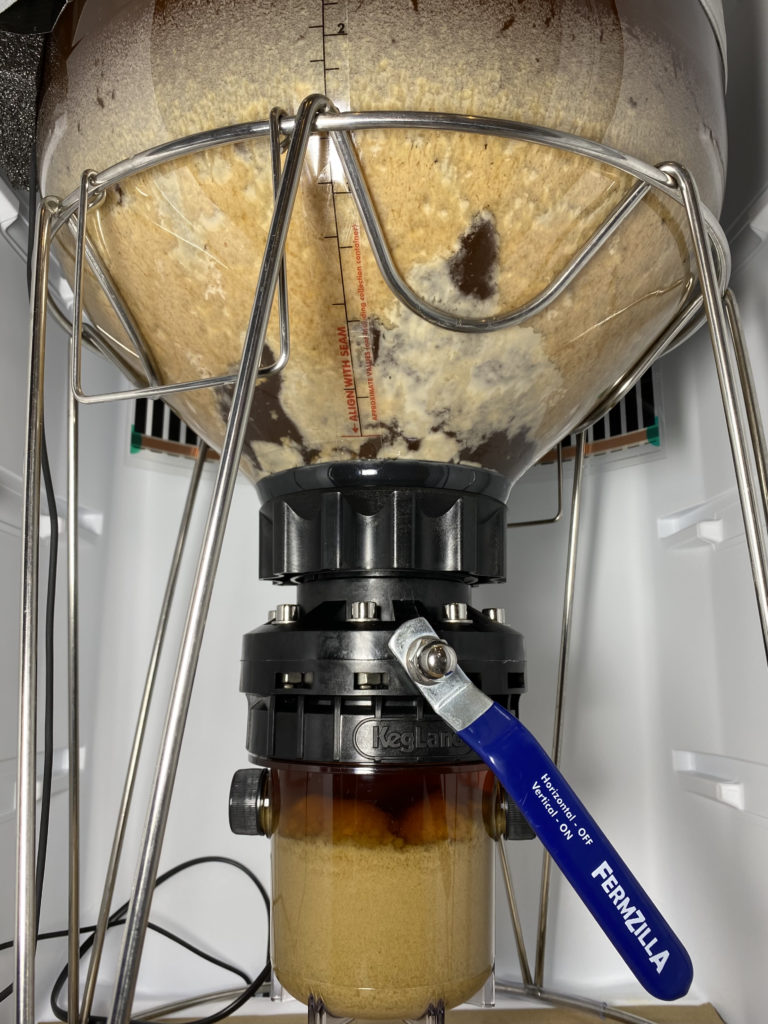

- Since I had carbonation caps fitted to the collection jar from purging the finishing hops, I thought I could cheat the floating dip-tube and collect some more beer by moving my Bouncer filter to the lower post. This turned out not to be the case, because despite the trub being lower that the post initially, as I drew liquid down I also caused some of the hops that had settled on the Fermzilla’s sides to slide down, which led to the carbonation caps becoming blocked. I ended up putting my line back on the floating dip-tube to finish off.

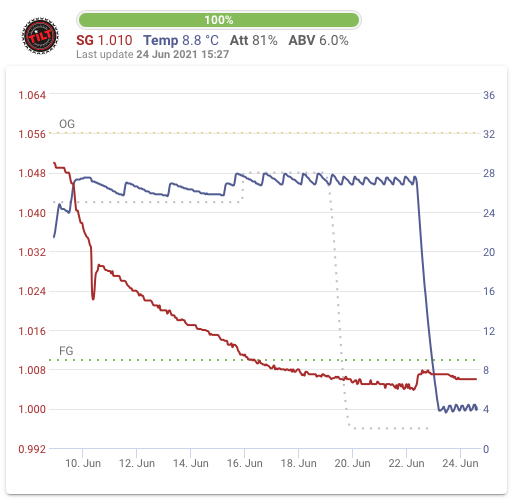

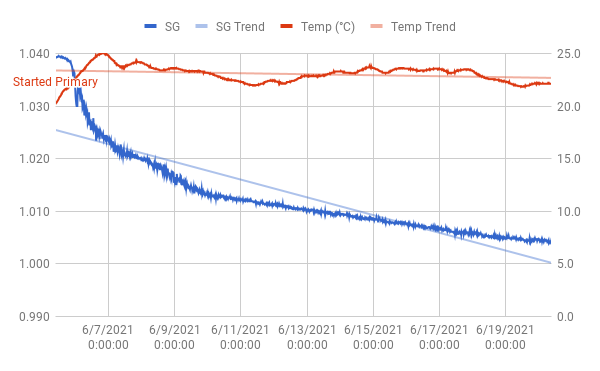

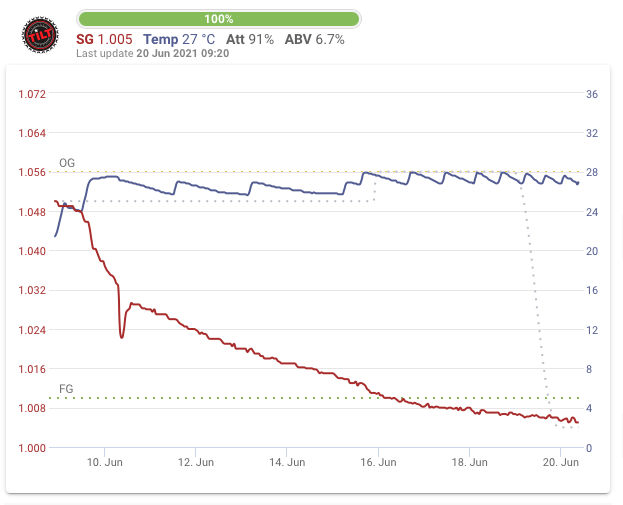

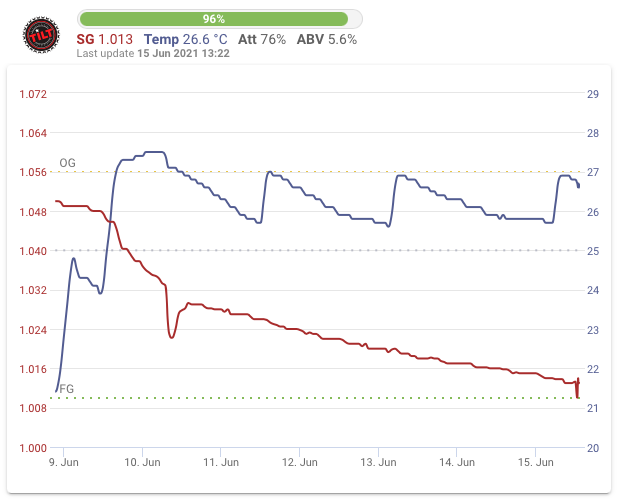

- The Tilt Pro continues to perform admirably, surviving pressure changes as well as cold-crashing. In fact the only sign of moisture inside is when I stupidly took it out of the chilled trub and washed it in warm water, causing some condensation to form in the top. Still, nothing on the batteries and circuit board, so I’m leaving it sealed.