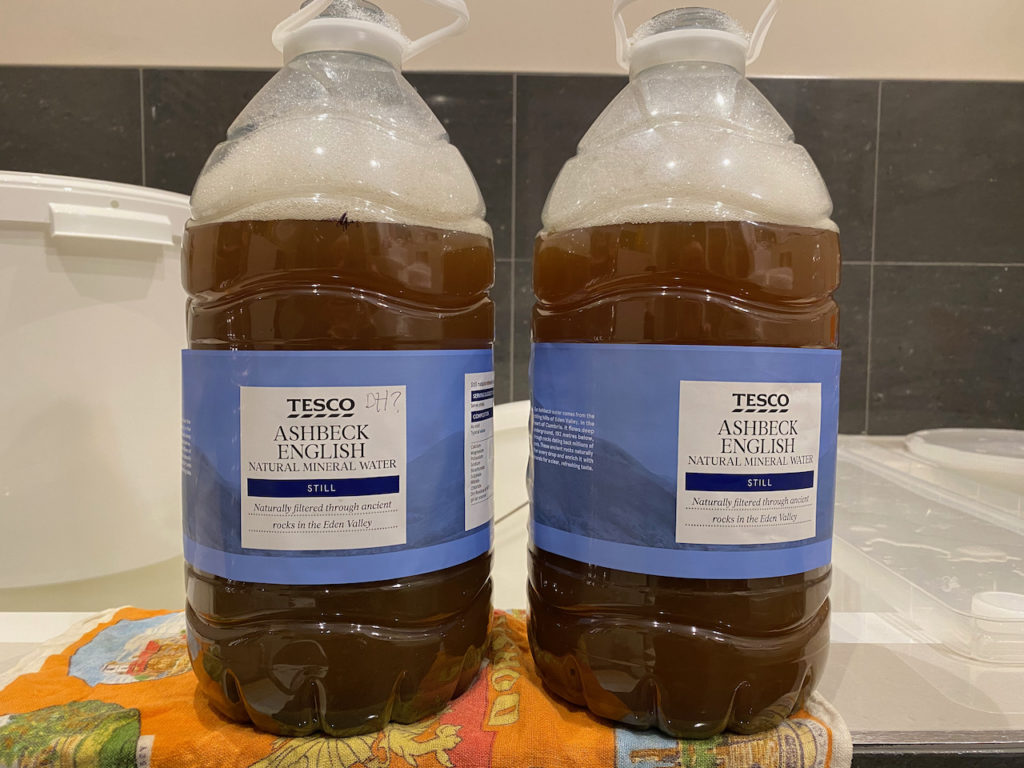

These should have been in the cold for 3 weeks now, let’s see how they’ve developed.

Update 02 March: there are only 3 bottles left. To think I could sit on something this good! Will definitely repeat this recipe at some point in the nearby future, this time using Citra (as planned!) for the dry-hop.