And with that, we’re done. This has been a great success, and as I write this I’m already in the process of kegging number two. I was pleasantly surprised by the hop retention, with strong flavours being there right until the end despite the bouquet fading after about 2 weeks. Very nice.

Geronimo

| Ref | 2022-09 Geronimo | Brewer | Pain & Patience |

|---|---|---|---|

| Style | New England IPA | Type | Beer, all-grain |

| Started | Thu 15th Sep 22 | Status | Archived, |

| Packaged | Mon 26th Sep 22 | Fermenter | Fermzilla |

| Handle | 2022-09 Geronimo |

|---|---|

| Brewer | Pain & Patience |

| Style | New England IPA |

| Type | Beer, all-grain |

| Fermenter | Fermzilla |

| Status | Archived, ABV |

| Started | Thu 15th Sep 22 |

| Packaged | Mon 26th Sep 22 |

Interesting evening. The substantial hop content had settled out nicely after a couple of days of cold-crashing, coming to rest on top of the almost closed butterfly valve, with the bulk of the dead yeast already in the collection jar and the remainder settled on the Fermzilla’s sloping sides. Would have been nice to get the hops on the sides and all the yeast in the bottom, but I guess you can’t have everything.

With all this solid matter settled so nicely I didn’t want to risk disturbing it by moving the FV onto my workbench, so I decided to transfer to get straight from the fermentation fridge, using CO2 to push the beer into the keg at 10 PSI with 2 PSI differential between spunding valve and regulator. At one stage I felt guilty about using the increasingly expensive gas so wastefully and switched over to closed transfer, but by then it was 22:00 and I didn’t have time for the slow rate of flow that resulted from such a small elevation difference, so I switched back to gas.

All went well until the floating dip tube touched the settled matter just below the 5 litre mark, at which point all flow ceased, and repeated clearing of the dip tube using gas failed to alleviate the problem. Later during cleaning I found a substantial wad of hops in the liquid transfer tube itself, so it looks as though this time it wasn’t the disconnect on the FV that was to blame, but regardless, I need to get into the habit of fitting a filter to the dip tube and another in the transfer tube, even if it means sanitising and purging more bits of plastic void.

In the end I gave up on the various blockages, deciding to cut my losses at 18 litres instead of squeezing out another two pints and risk oxygenating the whole keg. I knew it would be a lossy, hoppy monster and never anticipated using an overflow mini keg or even a bottle, but 3 litres of fermenter loss is quite a poor way to finish. Therefore:

#wisdom: use filters when transferring to keg. Use them. Filters.

There’s one more day to run on dry-hop but it’s not as if we’ll reach 1℃ for a good few hours yet, so I’m setting the Inkbird now. Hop utilisation will be much slower at low temperature so I don’t think one or two days extra hop exposure will hurt.

When I dry-hopped this brew 2 days ago I neglected to fit the floating dip-tube, and since we still have 2 days left to run (and the merest suggestion of continued fermentation) I thought I’d tease the lid off, fit the dip-tube, and re-pressurise using canned CO2, hopefully purging any introduced oxygen and increasing the spunding valve to 10 PSI in the process. I also gave the Fermzilla a gentle swirl, because the thick blanket of hops hadn’t moved since I added them. They’re now very well dispersed and it all looks great – will start cold-crashing tomorrow. I wasn’t originally going to do this, but there’s so much hop matter in here now that I really want to drop out as much as I can before sending it to the keg, even if I lose some of that legendary cloudiness.

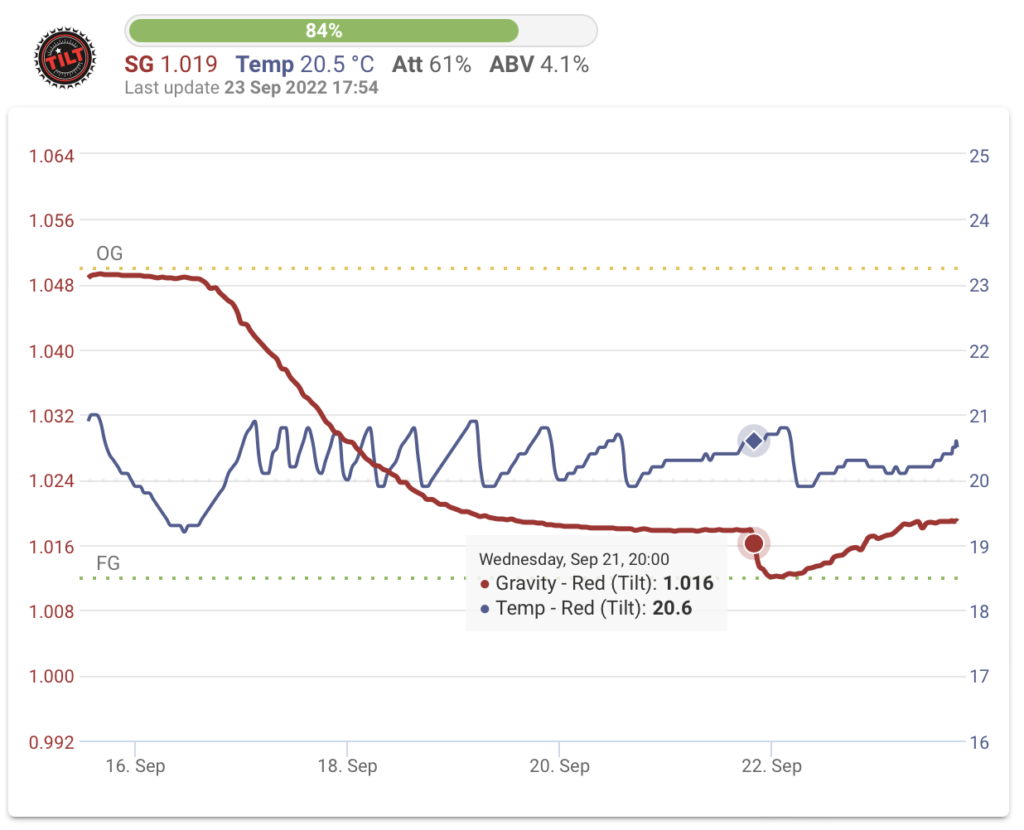

The Fermzilla’s been sitting at 5 PSI since primary started about 5 days ago, so I just teased off the top and chucked in 80g of Chinook, 50g Nelson Sauvin, and 40g Citra as per the recipe. No purging or faffing. There was a small island of foam at the centre of the brew, indicating that some slight fermentation was still going on despite the Tilt graph having been flat for 2 days now. That bodes well; I wanted a tiny bit of activity in order to dispel any introduced oxygen, so hopefully we’ll get minimal DO and still great hop utilisation.

Just a quick note to say that this brew has been sitting there idle for a good 26 hours since I pitched Omega DIPA “Conan” OYL-052, and I was getting worried.

But Allah Be Praised, she’s finally off! Not much to look at yet, just a blanket of fine foam atop the brew, not even touching the sides. But we have action, and that’s good. I don’t remember any other yeast taking quite this long … probably 12 – 18 hours, but not 26. Still, we’re off and that’s all that matters. The spunding valve had already hit 8 PSI by the time I caught it, so I dialled it down to 5. It’s not very precise or responsive at the lower pressures.

Go do your stuff, yeast.

Fairly good brew day today, the only mishap was spilling some of the whirlpool hops onto the steam hat instead of chucking them in cleanly. Well, that and a near boil-over when coming back from cutting the chiller in, but let’s draw a veil over that.

My numbers were still a bit off with losses of around 2 litres during mashing, which I made up for by sparging longer. I accounted for this using 2 litres fermenter top-up, adding another 2 litres actual fermenter top-up when I was left with only 19 litres after transfer.

On a positive note, I’ve been chatting with the creator of Brewfather via Discord, and learned that:

- Any gravity field in Brewfather expects a true, i.e. temperature corrected value instead of the raw value straight from the hydrometer, and

- Consistent losses in mashing can be dialled in by changing the grain absorption rate in the equipment profile. Right now that’s set to 0.8 (internet wisdom suggests 1.0 might be better) and I’m going to see if I can work out the numbers based on my findings rather than just fiddling with it.

#wisdom: enter temperature-corrected hydrometer readings in Brewfather, not raw values.

I also discovered that the sparge manifold can be used in vorlauf – and probably also during mashing – when I accidentally swapped it out for the mash hat before mash-out rather than after. Rather than undoing the change I simply removed the end caps so that the small holes along the bottom of the manifold wouldn’t get blocked, and it worked really well, distributing the wort better than the mash hat does. I’m not sure if the manifold arms are wide enough to work right from the start of a mash, or if it’d just get in the way of stirring and be a right pain, but it’s an interesting one to maybe explore later.