Had a sneaky glass of this today, but it’s blatantly not ready after 6 days at 12 PSI so I’m cranking it to 16 PSI and momentarily disconnecting the other kegs in the kegerator. Glad I’ve got a manifold with separate taps, shame I haven’t got separate regulators.

Yeti

| Ref | 2021-11 Yeti | Brewer | Pain & Patience |

|---|---|---|---|

| Style | Imperial Stout | Type | Beer, all-grain |

| Started | Thu 18th Nov 21 | Status | Archived, |

| Packaged | Thu 2nd Dec 21 | Fermenter | Fermzilla |

| Handle | 2021-11 Yeti |

|---|---|

| Brewer | Pain & Patience |

| Style | Imperial Stout |

| Type | Beer, all-grain |

| Fermenter | Fermzilla |

| Status | Archived, ABV |

| Started | Thu 18th Nov 21 |

| Packaged | Thu 2nd Dec 21 |

Standard procedure: gravity-fed line from SS Brewtech stainless bucket to liquid in post on Cornelius keg, pop the PRV, wait 15 minutes. Stick it in the chiller, pressurise to about 12 PSI. Wait.

This brew isn’t going anywhere else so I’m going to start crashing it now in order to be ready to keg before we go away on the 2nd, which frees up the fridge for one of the ciders – probably Allotment Riot.

It’s interesting to see a drop in temperature and then a spike over the last day or so. I think this is due to the brewery getting unnaturally cold due to some very high winds and the ventilation slit above the window being open. Room temperature is currently 13℃ and it’s been as low as 11, so I think what we’re seeing here is actually the inside of the fridge dropping low enough to engage the heater. Crazy weather!

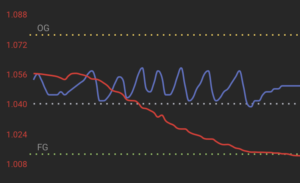

Fermentation has drastically slowed on Yeti. Brewfather’s graph shows a distinct flattening of the gravity curve just below expected FG, and the chiller’s cooling cycles have elongated and now stopped in response to a drop in yeast activity.

This isn’t unusual in and of itself, but I don’t think I’ve seen it just three and a half days after starting primary fermentation. The successful starter probably had a lot to do with it, so I’m going to flag this as #wisdom and will repeat the recipe (especially the timings) next time around. The only question now is whether I let it ride the full 2 weeks (and cold crash from 2-5 December while we’re away) or do I try to crash for a day and keg it early?

Not a bad brew day today, despite a persistent cold resulting in relentless sneezing and sniffling. But the starter was ready, so we have to press on. Briefly then …

The Good

Using my edited Brewtools equipment profile with the chiller empty at the start seems to be the way forward, with boil-off losses working out about right, but I need to remember to measure those levels before cutting the chiller in.

The Bad

I’m still losing a litre or so during mashing that I can’t account for, but that’s not the main problem: I need to get more regimented at measuring levels at the right time, and at setting reminders to deploy equipment like chiller and Trubinator correctly.

Even so I don’t see how I can be 10 points off post-boil and I’m going to blame this on the ingredients, all of which except 5.0 kg of Pale had been sitting around for a couple of months, albeit sealed in plastic bags and stored as cool as can be. Wonder how much better I’d do with my own mill?

Improvements

I need to sit down and run through the entire brew day in fine detail, maybe while the sparge water is heating, so that when it comes to implementing the plan I’ve not missed anything. Let’s do this by implementing a shortcode:

Continue readingKnocked up a starter for Thursday’s brew today, and it seems that about ¼ teaspoon of Lipohop is a good amount to prevent boil-over in the large Erlenmeyer with the quantities employed. I also used black DME this time around because I’ve got a bag knocking around, so why not?

- 1.5 litres water

- 185 grams dark DME

- ¼ teaspoon Lipohop

- ½ teaspoon yeast nutrient

- 1 packet Mangrove Jack’s M44 American yeast

Took about 90 minutes to chill down to pitching temperature after the uneventful 20 minute boil, yeast was added at 21℃ then it went onto the stir plate. Foam started to appear a couple of hours later, by the 24 hour mark we could call it Krausen and the temperature is up to 24℃, so I’m moving it to a cooler room in order to slow things down – it’s still around 18 hours until I’ll be adding this to the wort.

Continue reading