Both of these kegs were finished just now in order to make room for incoming brews.

Leftover Blonde

| Ref | 2020-09 Leftover Blonde | Brewer | Pain & Patience |

|---|---|---|---|

| Style | Blonde Ale | Type | Beer, all-grain |

| Started | Mon 13th Sep 21 | Status | Archived, |

| Packaged | Wed 29th Sep 21 | Fermenter | Fermzilla |

| Handle | 2020-09 Leftover Blonde |

|---|---|

| Brewer | Pain & Patience |

| Style | Blonde Ale |

| Type | Beer, all-grain |

| Fermenter | Fermzilla |

| Status | Archived, ABV |

| Started | Mon 13th Sep 21 |

| Packaged | Wed 29th Sep 21 |

It’s been cold-crashing for a couple of days, time to put this redundant Blonde into a keg and get ‘er drunk. Transfer method was the usual quick & lazy connection of both liquid out posts with a spunding valve on the keg and around 8 PSI going to the vessel from my cylinder. I filled approximately 18 litres into a corny keg and 2 litres into a 5 litre MJ mini. Off to the serving fridge at 10 PSI – will measure gravity later as I’m in a rush.

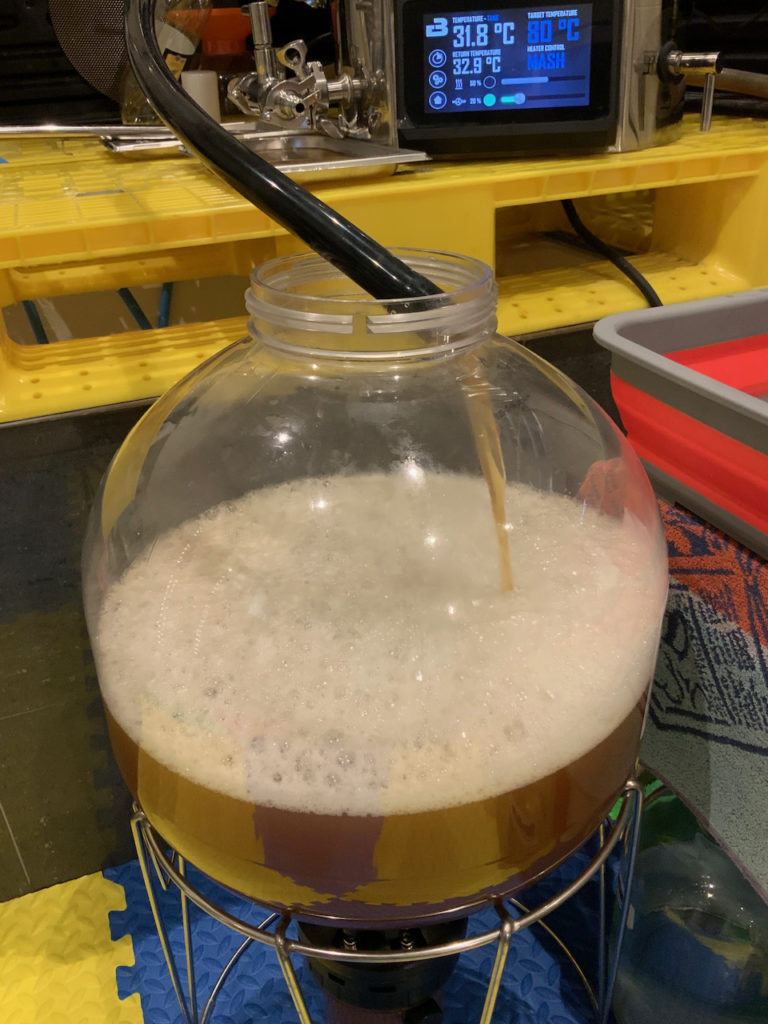

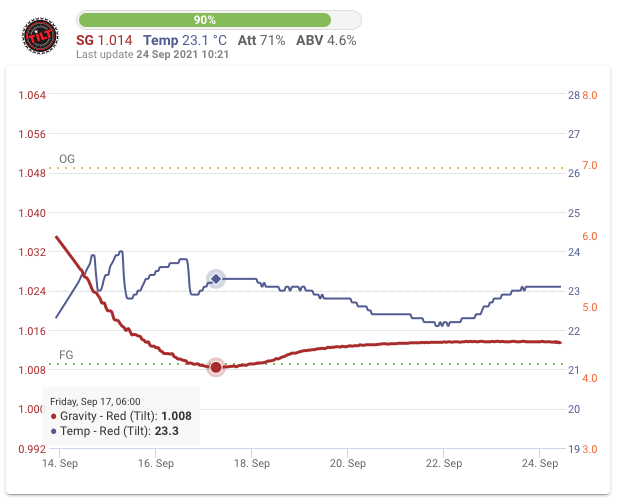

First the good news. Despite pitching the starter before it had reached peak Krausen – and going straight for 5 PSI – the brew really took off and by next morning there was a very healthy head in the Fermzilla, probably 4 inches and not far off the top of the vessel. At that point I increased the spunding valve to 10 PSI and two days later I had 100% attenuation, equal to about 5.3% ABV via the Tilt Pro.

But then something weird happened: the gravity started going back up. I’ve never seen this before. I’m now on day 11 and we’ve gone from 1.008 on day 3 to 1.014, equal to 71% attenuation and just 4.6% ABV. Could this be an infection or other contamination? My hygiene has been good as usual (though I bet everyone thinks that) and I’m wondering if the brew would have reached peak as far as it did had there been any contamination.

Could it be something to do with the starter? I used a ridiculously small quantity of WLP518 and pitched before the starter was 100% ready, but once again, I had it down to 1.008 in 3 days so … WTF?

One thing you can never rule out is that there’s some stray Krausen stuck to the floating hydrometer and affecting the reading as it breaks down, but while the first generation Tilt was partially susceptible to interference in this way I’m using the Pro version, which is significantly bigger and has never had such issues in the past.

Since I’ve nothing to lose either way I’m going to leave this ferment to ride out and will cold-crash as planned in 3 days time, and then I’ll measure the gravity using my ‘manual’ hydrometer before kegging. As always, fingers crossed.

Retrospective entry made 24 September: peak attenuation has been reached 17 September 06:00 at 1.008 / 5.3% ABV and has since been dropping again.

Another day, another brew. This time I’m using up some odds ‘n’ sods in my inventory without really aiming for anything specific, other than a light-ish ale of 5% ABV or less.

Also being used up is a tiny amount of Opshaug Kveik that was scavenged from a previous brew and has been sitting in my fridge for an indeterminate number of weeks. I made a starter from this but it hadn’t really taken off by the time I wanted to pitch, so I left the wort in my fermentation fridge for a few hours until I decided whether to chuck in the starter as-is or pitch some dry yeast instead. In the end I threw in the Kveik and I’m glad I did, because by next morning it had gone ballistic!

Sparge Success

Back to the brew day itself, and everything went pretty much according to plan. I used the new sparge attachment from Brewtools during the sparge stage and it worked flawlessly, giving a nice even spread with just the right amount of flow. The only difficulty was getting the mash hat off the centre pipe in order to fit the sparge tool, a process that took a lot of wiggling. Maybe some more silicone grease will help next time. At any rate I don’t think I can use the sparge tool for mashing as well, the holes are very small and likely to block up and those six arms will probably get in the way of my mash paddle.

Learning Opportunity

For the past couple of brews I’ve been filling my entire system with mash water on the evening before brew day, including the chiller coil and link pipe, then reading the levels off the internal scale with the malt pipe fitted. I’m now wondering if that’s the right thing to do. Yes, there will be slightly less chiller loss if the chiller is full of water rather than air, but that water will dilute the wort (and therefore skew boil efficiency) as the chiller is cut in 15 minutes from the end of the boil. Maybe I should leave the chiller and link pipe dry when adding mash water and just accept a higher loss in that respect than trying to fudge things by adding water to the chiller and plumbing, which isn’t going to be represented by the internal scale since that has no idea what’s connected to the kettle. Need to look at the numbers and revisit this.

Raw Brew Day Notes

08:30 – Heaters on 100%, water at 19℃, target 68℃.

08:57 – Heaters to mash mode, starting dough-in

09:03 – Dough-in complete, starting 20 minute timer for the mash rest.

09:23 – Mash rest complete, time for first stir and to start circulating through the centre pipe. First a quick look at levels: around 26 litres. Brewfather predicted 25 litres.

10:04 – Just under half an hour left to run on this mash, and it’s been a bit sticky here and there, requiring constant adjustment of the flow balance and some stirring. I’ve thought about fitting my new sparge attachment which is supposedly also suitable for mashing, but I have a feeling that the holes will get blocked up quickly and that it’ll be in the way of my mash paddle when stirring. Can’t wait to try it out during the sparge though.

10:34 – Mash complete, raising temperature to 71℃ for a mini mash-out while waiting for the levels to settle. Post-mash gravity 1.059 (1.042 @ 62.8℃). Looks like about 24 litres in the kettle prior to sparge.

10:44 – Starting sparge with new hat fitted … HLT temp 73℃. Really nice level of control, good water distribution. HLT ball valve open all the way, pumps at 20%, occasional pause as water builds up on top of mash.

10:52 – Sparge complete, letting her drip for a while with heaters now at 100% approaching boil.

11:00 – Malt pipe removed, pre-boil volume 26.5 litres (BF: 28.86) pre-boil gravity 1.049 (1.027 @ 70.8℃, BF: 1.043). Looks like I’ve lost a tad more liquid during mashing and bumped up the gravity instead. Let’s see how that looks after boil.

11:23 – Added 1/4 tsp Lipohop while stirring the hot break in, keen to see if it makes any difference as it has when I use it for the starter. Temp 98℃.

11:26 – Boil tracker started, added 11.7g Chinook, reduce heater to 60-65%, steam hat on.

12:08 – 15 minute boil additions in, getting ready to include the chiller coil for sanitation.

12:28 – Boil complete, chilling to 80℃ for hop-stand and final additions. Steam hat removed.

12:32 – Starting 20 minute hop stand, added 20g Chinook. Post-boil kettle volume is 24.5 litres (BF: 26.46) post-boil gravity 1.049 (1.028 @ 68.4℃, BF: 1.047). I’m guessing that the water in the chiller has absorbed some of the gravity points gained as a result of mash losses, so next time I may leave the chiller empty when filling the mash water.

12:57 – Starting to chill ahead of FV transfer.

13:38 – Transfer finished, but the starter’s not ready yet. I’ll put this in the fermentation fridge at 23℃ for a couple of hours while I decide whether to pitch the starter anyway or throw in a couple of packets of dry yeast instead. Deploying blue tilt while I’m here. Looks like around 19 litres only in the FV, which is a shame. Ton of trub in the kettle though.

15:00 – Clean-up finished.

21:00 – Pitched yeast starter at 23℃

Recipe

Malts (4.65 kg)

- 1.25 kg (26.9%) — Crisp Clear Choice Malt ® Ale — Grain — 5 EBC

- 1 kg (21.5%) — Thomas Fawcett Pale Malt, Golden Promise — Grain — 5 EBC

- 1 kg (21.5%) — BestMalz Pilsen Malt — Grain — 3.5 EBC

- 500 g (10.8%) — Crisp Extra Pale Maris Otter® Malt — Grain — 3 EBC

- 500 g (10.8%) — Simpsons Rye Malted — Grain — 4 EBC

- 400 g (8.6%) — Simpsons Caramalt — Grain — 36 EBC

Hops (51.7 g)

- 11.7 g (15 IBU) — Chinook 11.8% — Boil — 60 min

- 20 g (14 IBU) — Chinook 11.8% — Boil — 15 min

- 20 g (4 IBU) — Chinook 11.8% — Aroma — 20 min hopstand

Sunday, 15:00

I used a tiny amount of harvested Opshaug that’s been in the fridge for an age, and if this works I’ll frankly be amazed. There can’t have been more than a tenth of a packet, so I plugged 0.05 packs into Brewfather’s starter calc and it recommended 1.5 litres of water with 150g DME. Threw in some Lipohop and plenty of yeast nutrients and hoped for the best.

Monday, 08:30

Nothing happening, so I’m switching off the stir plate to give her a chance to gather her thoughts.

Monday, 11:00

I’m halfway through brew day and the yeast starter still looks dormant apart from some isolated bubbles rising at the edge, so I switched on the stir plate again in case she needs more oxygen. The effect was immediate, with enough bubbles coming from the bottom of the flask to form a good head, which started filling up the neck straight away. So there’s definitely something happening, but I’m not sure I’ll reach high Krausen by the time I’m ready to pitch in a couple of hours. Keep the wort ready in the FV until this evening? This will be interesting!

Monday, 21:00

The starter has been bubbling away on the stir-plate for most of the day, increasing whenever shaken and slowing down when left, but it’s the gradual change in colour from dark, russety brown to a light, warm toffee hue that convinced me to pitch this now. Or maybe it was the sentiment it’s Kveik, innit?