It‘s been 4 months since this was bottled – time to crack one open.

Ballacowin Blush

| Ref | 2021-10 Ballacowin Blush | Brewer | Pain & Patience |

|---|---|---|---|

| Style | Experimental | Type | Wine, raw |

| Started | Wed 20th Oct 21 | Status | Conditioning, |

| Packaged | Mon 15th Nov 21 | Fermenter | SS 10 litre Bucket |

| Handle | 2021-10 Ballacowin Blush |

|---|---|

| Brewer | Pain & Patience |

| Style | Experimental |

| Type | Wine, raw |

| Fermenter | SS 10 litre Bucket |

| Status | Conditioning, ABV |

| Started | Wed 20th Oct 21 |

| Packaged | Mon 15th Nov 21 |

Nine days of cold-crashing at 1.0 ℃ ought to just about do it, time to get her put away. I don’t own a cork press, and in any event 750 ml might be too much of this in one go, so I chose to fill some clear 330 ml crown-cap bottles instead.

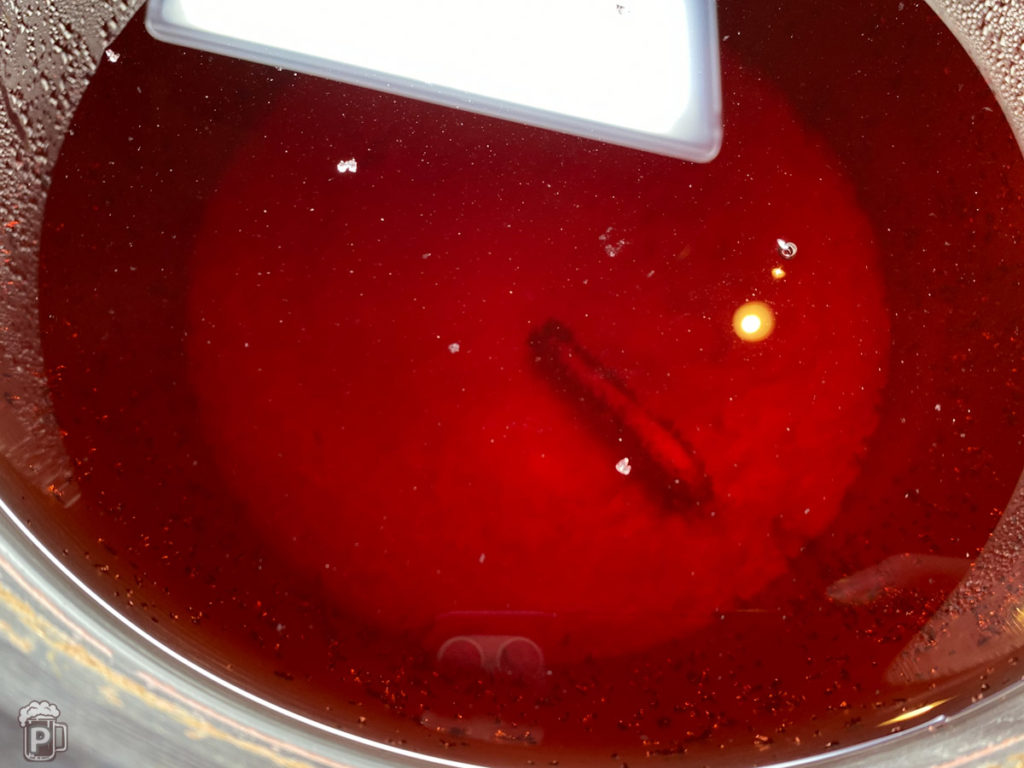

Final gravity comes in at 1.000 exactly (1.002 @ 7.7℃) which makes for a final ABV of 8.7% – not bad at all. Colour is a lovely pink and there’s some excellent clarity, with quite a bit of gunk having dropped out during cold-crashing. The only thing that worries me is the decrease in 2 gravity points during crashing hints at some fermentation still in progress, and I didn’t leave a lot of headspace in the bottles. Maybe I should have added another Campden tablet before bottling? I’ll keep an eye on them as we progress. At least I had the presence of mind to also fill a single plastic screw-top which can serve as a pressure gauge.

Finally, some weird red crystals had formed on the insides of the Brewtools bucket and on the dip tube. These were quite hard and regularly spaced – wonder what’s up with that?

No idea of the gravity (pushed for time today) but there’s been no airlock activity of late so it’s probably time to see if we can get this cleared and put away. Shoved it in the fermentation fridge as soon as Sarka came out, dialled in at 1℃.

There’s not much going on at the airlock, and the top of the brew has lost all traces of foam. SG weighs in at 1.001 for 8.5% ABV and the taste is quite dry, certainly less sweet than last time. I think another day or two and we’ll stop this, but it’ll need clearing up as it’s still fairly cloudy.

Fermentation picked up well after a day or so of pitching the yeast starter, and the airlock bubbled away happily for 3 days at 1-2 pops per second. Since yesterday it’s slowed down to just 1 pop every 4-5 seconds, so I took a gravity reading: 1.004 for about 8.1% ABV.

The colour’s lovely and the taste … is not bad, but there’s still a strong flavour of grapes rather than wine, and some sourness, although there’s sweetness present too. It’s too sharp for Patience, but I’m happy to finish off the contents of the sample jar without protest.

What to do now? I think that if I stop fermentation with a Campden tablet then we’ll still have the sweetness, but also the slightly sour edge which might translate to a rough finish with ageing. Let’s leave her to it for another couple of days so that the yeast can clear up after itself, even if it means losing some of that sweetness.

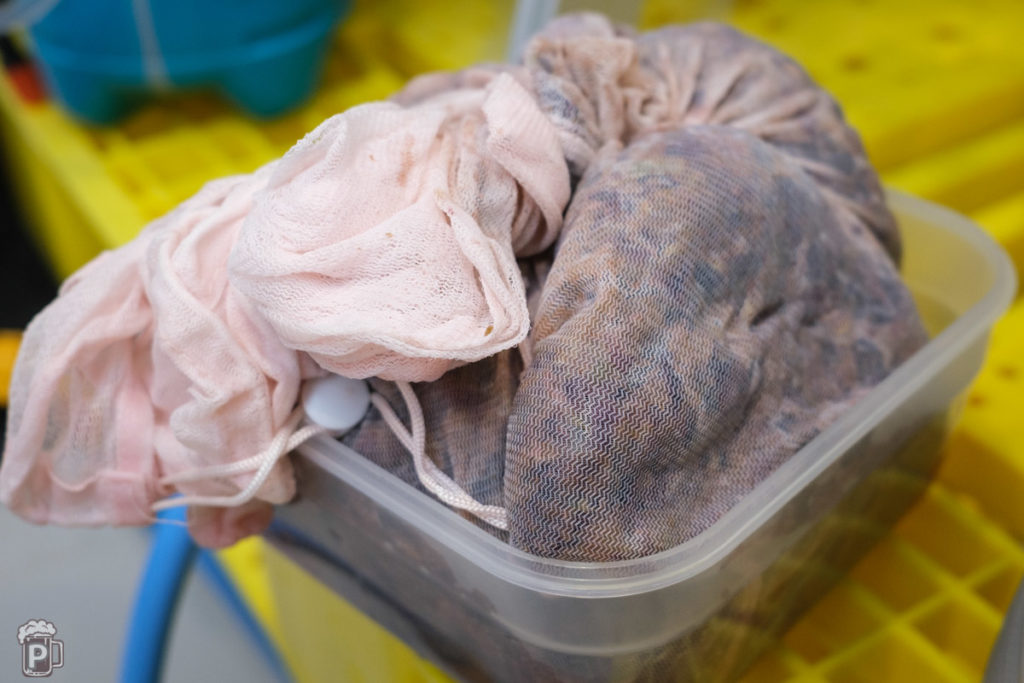

I have no idea what I’m doing here, this being my first attempt at making wine. Our initial idea was to use a potato masher of German design to squeeze one handful of grapes at a time and then put the skins to one side for later inclusion, but this didn’t work out, presumably because the first layer of skins blocked up all the small holes in the device and led to a kind of hydraulic lock.

A fall-back option would have been to use the same bladder press that we use for cider, but that needs to be full before it can be used and I’m not sure we have enough grapes for a complete press. A workaround would have been to fill the press with the bladder partially inflated and make room by letting out water as needed, but then we may still not have enough squashed material at the other end and could end up overloading the bladder. The risk of contamination also isn’t ideal; cider is a fairly robust tipple and I’m not sure if grape juice has the same tolerance for contamination, so using a cider press didn’t sit well with me on principle.

In the end it was suggested I use another potato masher (this time a traditional British design) to stomp the grapes in their plastic buckets, which seemed mechanically similar (and hygienically superior) to stomping it using our feet. So I mashed them up last night as best as I could, which isn’t saying a lot since the smaller, firmer fruit was easily ejected to the side of the masher once a slippery slime was made using the riper fruit. Looking back I think I only macerated something like 60% of all grapes.

Having left the skins to soak in their juice overnight we started again this morning, and this time I decided to manually squash the remaining fruit literally by hand before bundling it into a muslin bag and squeezing it out over the bucket. It soon became apparent that I’d need the full complement of both types of fruit, and the combined effort yielded about 9.5 litres, into which I pitched the yeast starter I made last night.

Before pitching I checked the OG which came in at about 1.066. That should translate to 8.7% if we’re aiming for a semi-sweet wine, according to Brewfather.

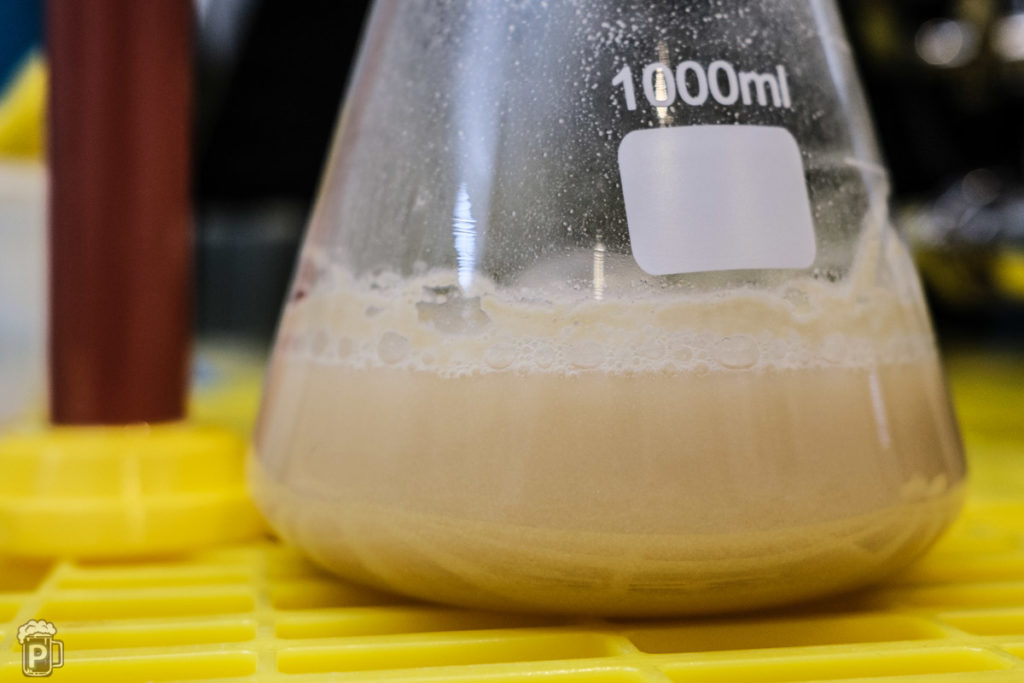

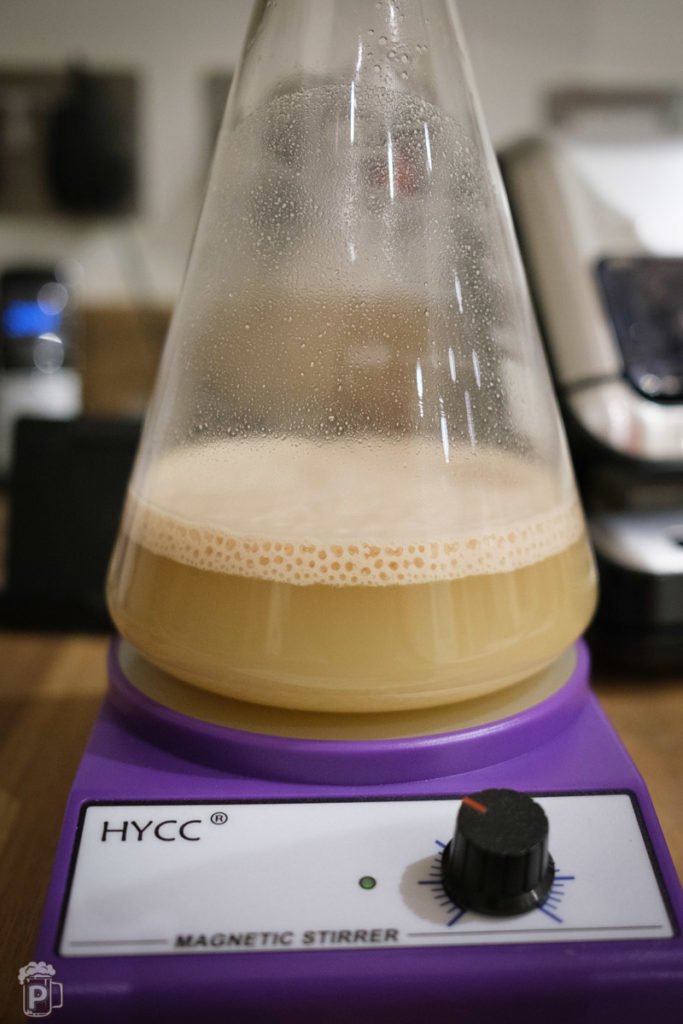

I’m going to make a starter instead of pitching dried yeast for two reasons; it’s always worked very well with my beers, and the only wine yeast I have went out of date six months ago. Setting it off on the stir plate with plenty of oxygen and nutrients should have a positive effect on the viable cell count, and if nothing at all happens then at least I’ve only contaminated a small sample of my must.

In the end it actually worked out quite well. I took 400 ml of must from the first mashings and added it to my medium Erlenmeyer flask along with approximately one teaspoon of dried wine yeast and a generous helping of wine yeast nutrient before placing it on the stir plate. Absolutely nothing happened for a couple of hours, and then in the space of ten minutes we saw the first signs of foam at the top.

I gave her a good shake and increased the speed of the stirrer because I didn’t want Krausen just yet, and it continued to stay headless until the morning, by which point a good amount of foam could be summoned by switching off the stirrer and letting it sit for a moment.

A friend kindly donated the fruits of his vine to us this year, and today it was time to harvest. One side of the greenhouse contained small, black, very ripe fruit, the other had larger but greener grapes. We grabbed all of the former and as much as we dared of the latter, reasoning that we really wanted only very ripe fruit but there might not be enough to fill the 10 litre fermenter I’m planning to use. This way we could see how far we get with the good stuff and then top up from the less ripe crop.

The fruit was taken to Port Erin for dressing, where we washed the grapes before de-stalking them and taking them back to base for processing.