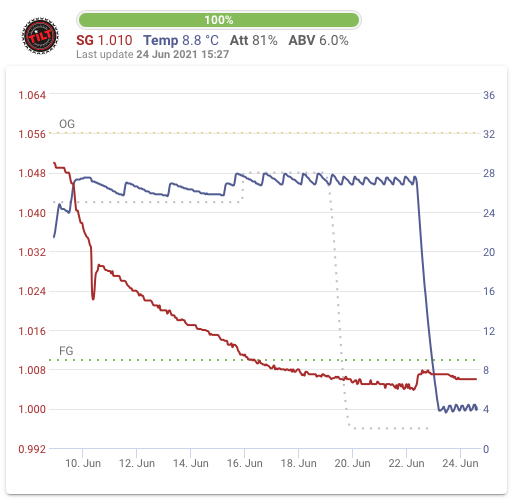

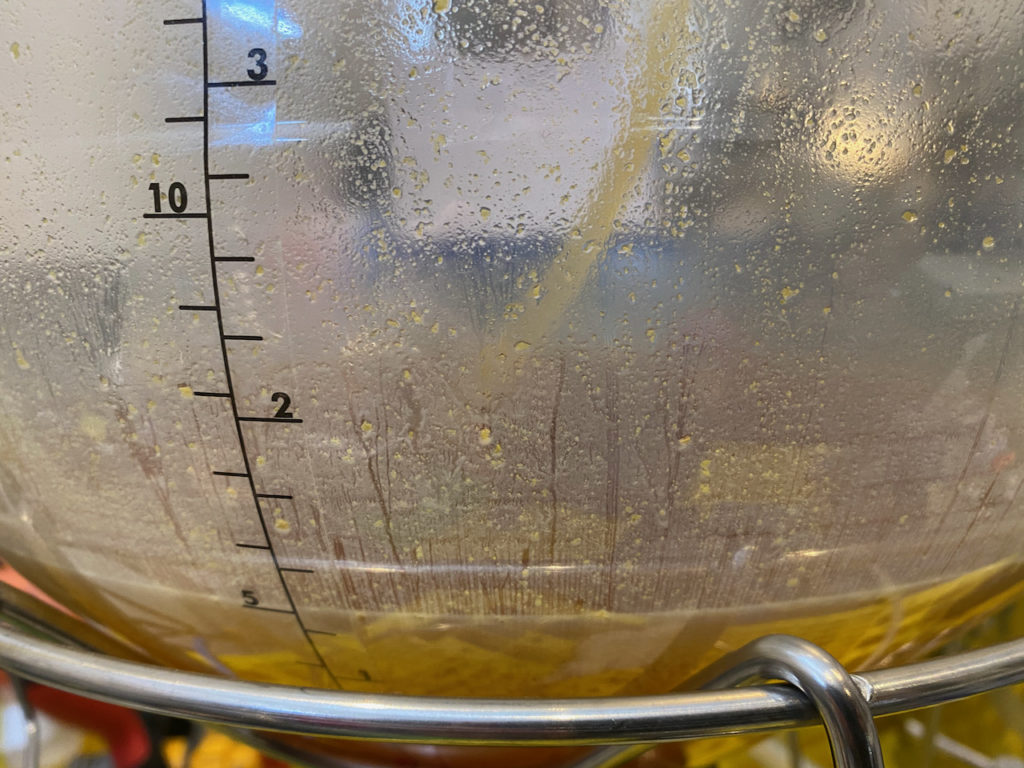

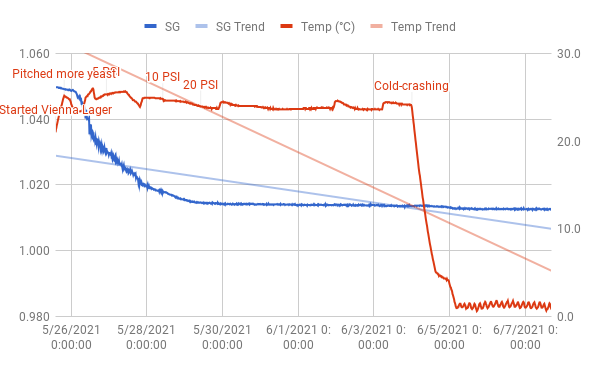

I’ve just put away 19 litres into a Corny keg and some leftovers into a plastic bottle. Cold-crashing had done a great job of dropping out any stray meatballs and also lightened the colour of the brew considerably, so there’s hope yet. Tilt reports FG 1.008 for 3.4% ABV and I’m fine with that, though I’ll take a reading with the analogue hydrometer at some stage because I’m curious to find out if the age of that yeast has had any impact.

Tag Archives: kegging

I just put away a full 19 litre keg using standard gravity transfer into a purged Corny. There looked to be about 2 or 3 litres left over, but instead of going for a second mini keg I just dumped it into a plastic PET bottle. No issues.

I’ve just put away approximately 15 litres via gravity transfer to a purged 19 litre Corny keg, which also received half a crushed Campden tablet. The keg was placed on CO2 at 20 PSI. No time to measure gravity – got my hands full with an unexpected boiler leak in the utility room.

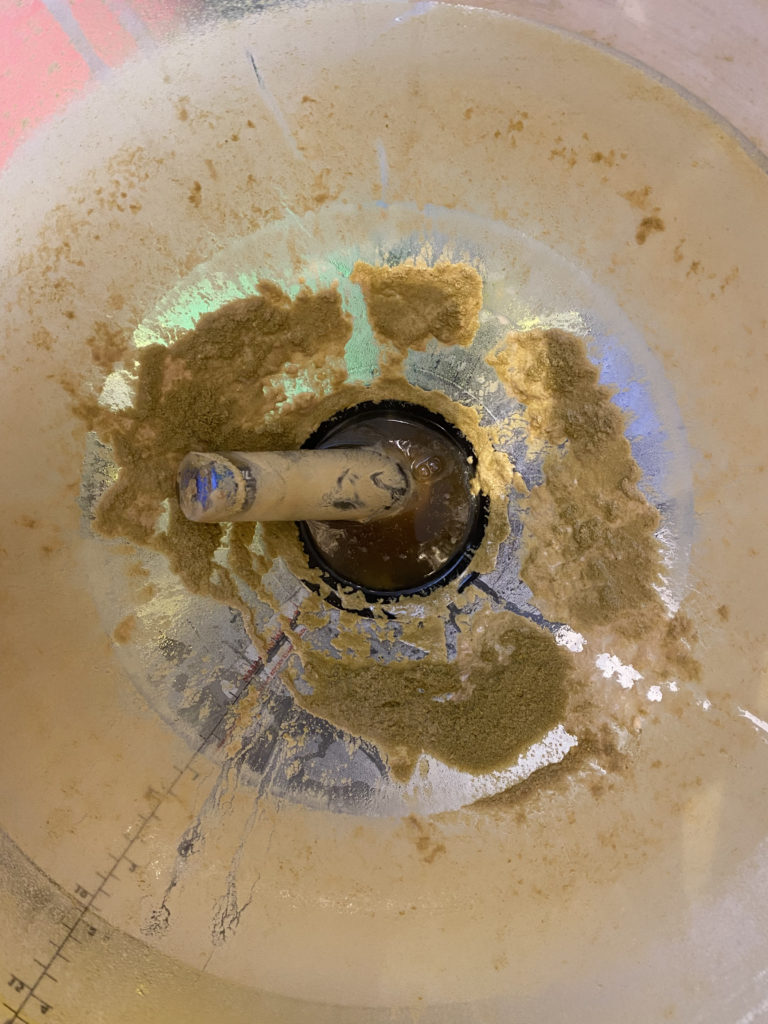

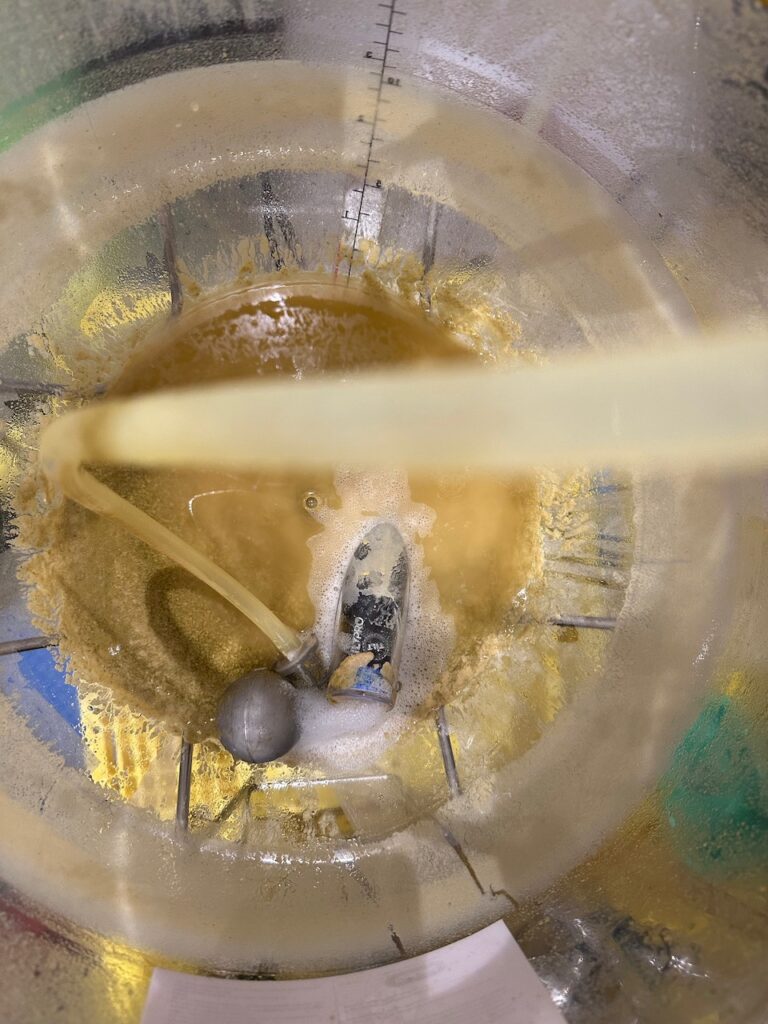

One final observation was that the Krausen trace inside the fermenter was a good six inches tall, which I’ve never seen before. Good job there weren’t 20 litres in there, would have made one helluva mess of the fermentation chamber!

Approximately 8 litres went into a 10 litre MJ mini keg which was then put on 15 PSI brew gas, think it’s 70/30 mixture. Not really too bothered if this doesn’t add any carbonation, I’m just keen to get it out of the fermentor and put away.

I also bottled 6 or 8 plain 330 ml lager bottles, each with 30 ml Erythritol and one carbonation drop. The sugar was poured straight in and hadn’t really dissolved when I checked a week later, but the carbonation drops were gone. Let’s leave these alone for a couple of months and see what happens.

I just filled one sanitised, purged Cornelius keg and hoped to get another 2 or 3 litres into an MJ Mini, but as soon as I started transferring to the second vessel it became clear that there was mostly just hops left over. In the end I think we got just over a litre into the second keg, which was hardly worth bothering with.

#wisdom: when kegging a hop-forward brew like Geronimo, FV volume of 21 litres is about right for a 19 litre Corny.

Kegged 24 litres just now; 19 into a Corny and 5 into an MJ Mini. There’s practically no headspace in those kegs so I think we may have some very slow carbonation, but that’s fine as I plan to condition this one for as long as possible.

I did notice that during cold-crashing the pressure I added via a Sodastream cylinder was very quickly absorbed, which makes me think that I’m still having difficulty sealing those stainless carbonation caps. When prepping the FV ahead of brew day I saw that I overtightened one or two of them and had to re-seat the seal, so perhaps that caused the pressure to drop at the end of fermentation when CO2 was no longer being produced. Odd.

#wisdom: prepare Fermzilla ahead of brew day, leave pressurised long enough to highlight any issues with loss / leaks.

Quick and sloppy gravity transfer to a sanitised and partially purged 19 litre Cornelius keg.

Just put away 18 litres into a standard Cornelius keg. With just 19 litres in the fermenter I was expecting to lose a bit more, but there wasn’t all that much gunk in the bottom so we got away with quite good yield.

Usual method of purging sanitiser filled keg with CO2, carefully throwing in half a crushed Campden tablet, then purging some more. Didn’t bother doing the lines this time, and got pretty much one full Corny keg out of it with not much left behind but hops and trub. Brewhouse efficiency is down a bit as a result of 2 litres lost post-fermenter, but I’m happy with the filled keg, especially as any more would have seen me dirtying another vessel for the sake of one or two pints. Gravity is 1.014 versus expected 1.012, equating to about 6.6% ABV instead of expected 6.9%. No complaints from me!

Not much to say really, just quick & dirty gravity transfer into a sanitised, partially purged Cornelius keg. FG turned out to be just 1.024 so we’re looking at 8.0% ABV when it’s done. Could be better, could be worse.

Just put away about 19 litres of this into two kegs; a 10 litre MJ Mini and the rest into a standard 19 litre Corny. Not sure why I used a full-size keg to hold just over litres but by then I’d already sanitised it, so why not.

I’m slightly disappointed to only get 19 litres from the FV when there was just over 21 to be had. The trub line wasn’t above the disconnect I’d fitted to the collection jar (light beer, sparse hopped) so I started using that to draw off, but the flow stopped 3 or 4 litres into the first keg despite adding 10 PSI using a mini CO2 cylinder. In the end I went back to the floating dip-tube, which I still haven’t weighted properly and which is therefore still not going all the way down, especially when it starts fouling the Tilt. Oh well.

On a positive note I’ve measured FG at 1.011 so we’re looking at 4.7% ABV, 0.1% above the anticipated final and that’s more than acceptable as bang-on given the likely margin of error when checking a partially carbonated brew. Slightly more cloudy than I’d have expected given the 3 days of cold-crashing and use of Protafloc, will probably clear if lagered for a couple of weeks, but that seems unlikely because the taste is already very moreish despite lacking body. Into the fridge at 15 PSI of CO2 for a couple of days.

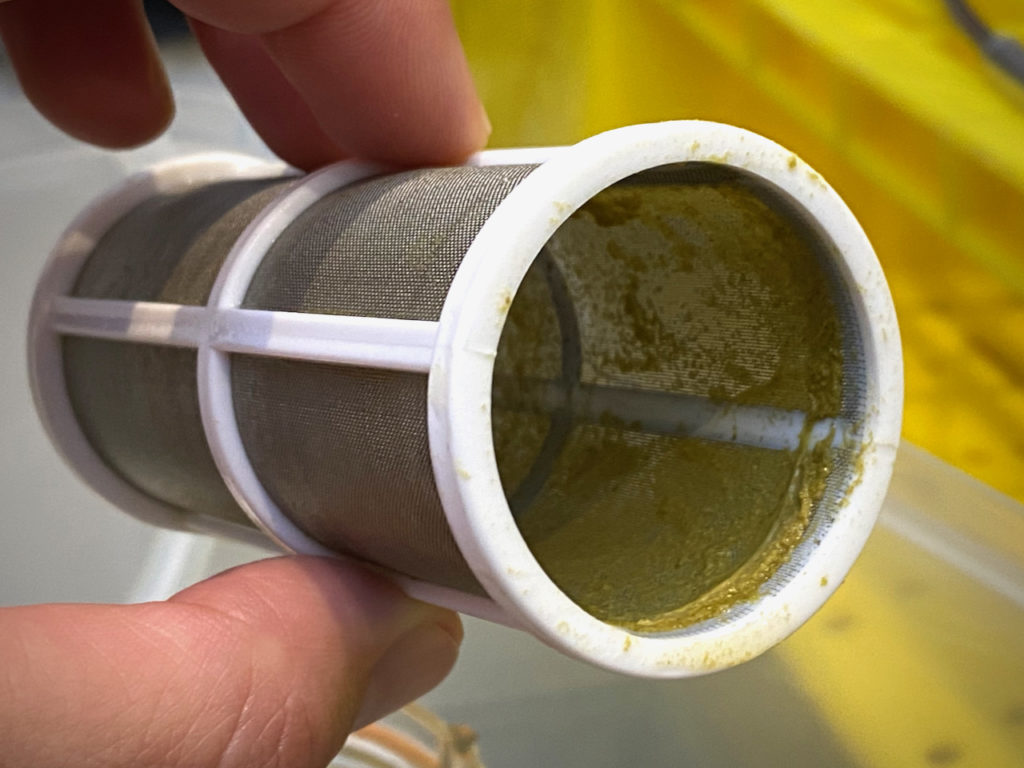

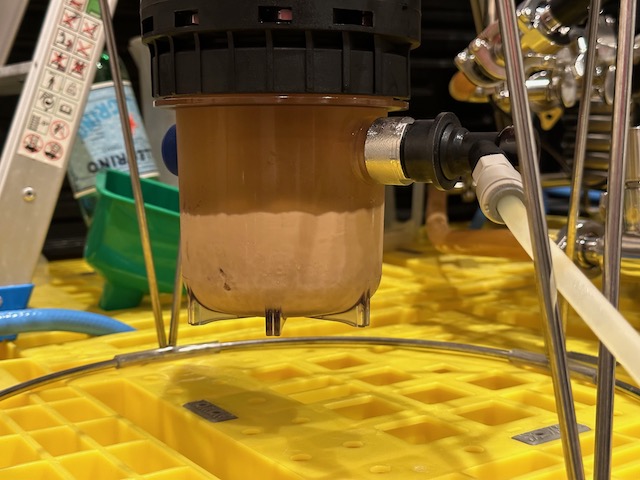

Quite a bit of hop debris this time and also a crazy amount of spent yeast, given that I only pitched half a packet. At any rate, the collection jar was solid with grey gunk and the sides of the FV were covered in green, so I guess the cold-crashing worked on both counts.

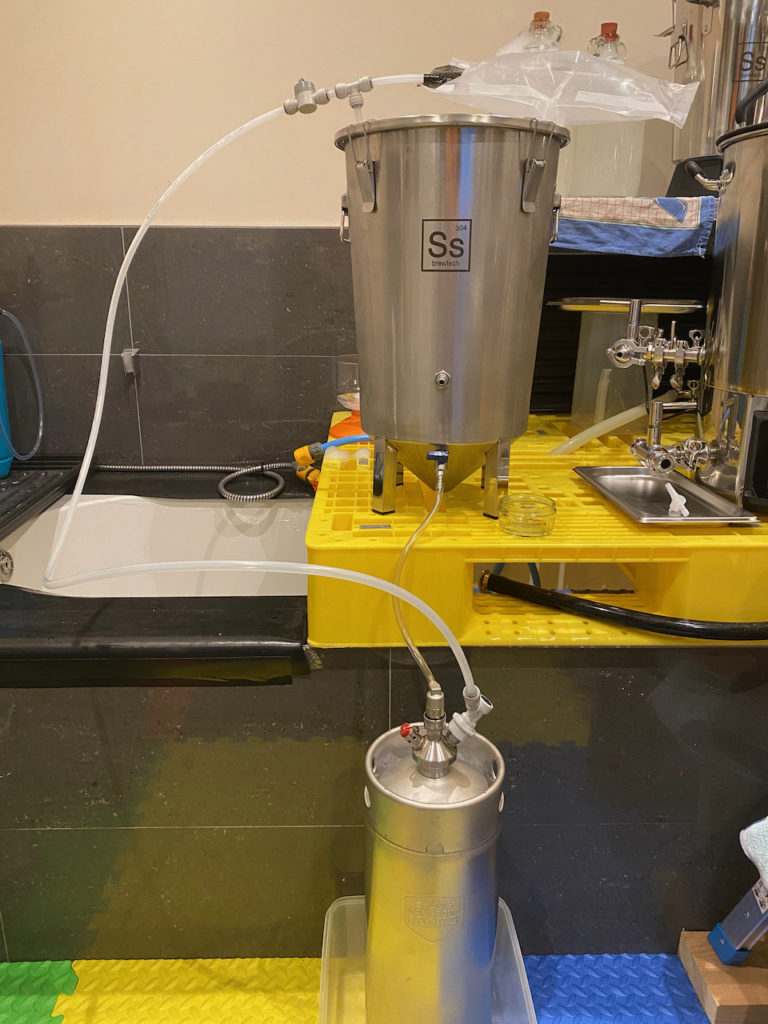

Transfer was into fully purged keg using purged lines for gravity-fed closed loop. The filter on the floating dip-tube worked OK but I’m going to move the weight onto the end of the filter housing, and maybe shorten the tube a little so that it doesn’t snag on the sides near the bottom, Realistically there wasn’t much left behind in the FV amongst all that trub, but I did have to coax the dip tube along towards the end by tilting the vessel.

I just put away around 17.5 litres into a 19 litre Corny keg, gently purged with CO2 but not filled with sanitiser first – doesn’t seem to be a lot of point with this brew as there aren’t too many hops. Transfer method was standard gravity, purged the liquid lines too but left the top off the FV and didn’t feed gas back in. My thinking is that the top half an inch is left behind in the vessel anyway, so if that’s exposed to O2 then what the hell. The brew was cold-crashed to 3.0℃ (wouldn’t go any lower – strange) for a day. Putting on CO2 in the brew fridge at 15 PSI because I’m impatient.

Put away a full keg plus two sample glasses from an indicated 21 or 22 litres. The new filter on the floating dip tube worked well and there was no clogging, with minimal sediment in the last two glasses pulled.

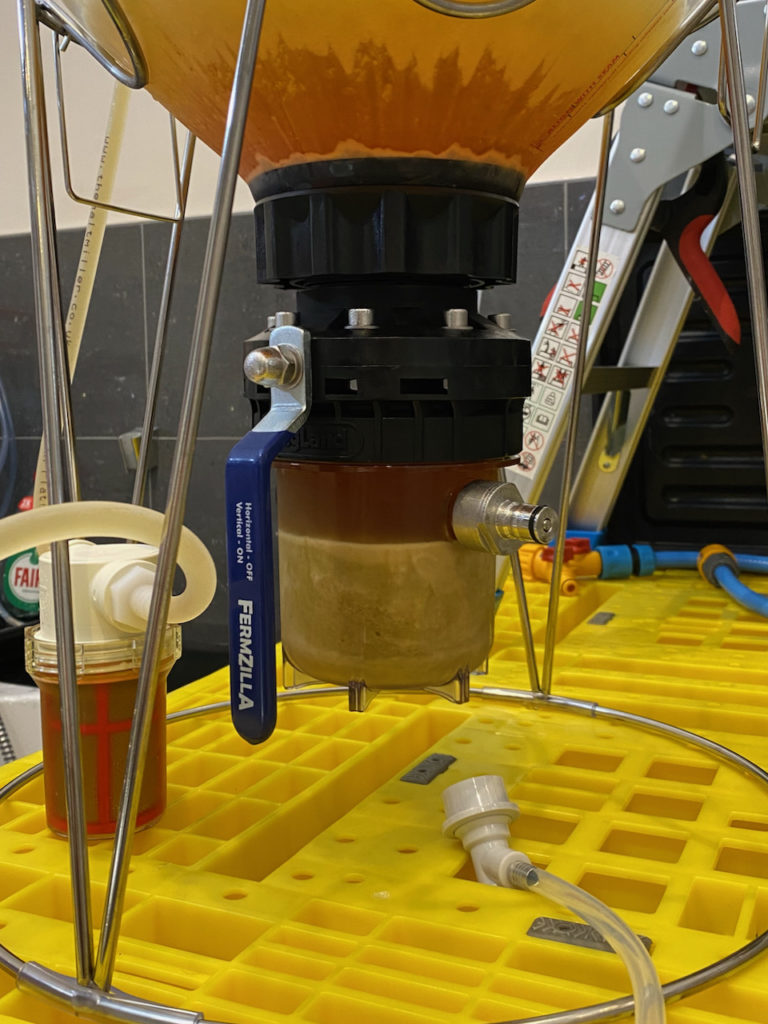

I’m undecided whether or not to fit a second filter to the collection jar. Standard practice ahead of cold-crashing now is to almost close the butterfly valve on the mostly spent yeast that’s collected below, so that the finishing hops don’t all fall into the same pit, and that the exposure to spent yeast is limited. This seems to work well, with any subsequently settling hops staying out of the jar and falling onto the Fermzilla’s sloping lower sides.

The upshot of this is that there appears to be some clear liquid above the yeast in the jar, and I’m wondering if I can tease out another couple of litres instead of losing between 1.5 and 2.5 litres to trub on each transfer. The answer is probably not, for what transpired to be reduced dip-tube final mobility thanks to adding the filter actually turned out to be the filter coming to rest on a bed of hops atop the butterfly valve, in which case we won’t be pulling much liquid down via the secondary filter anyway. Still, might give it a go next time around.

Interesting evening. The substantial hop content had settled out nicely after a couple of days of cold-crashing, coming to rest on top of the almost closed butterfly valve, with the bulk of the dead yeast already in the collection jar and the remainder settled on the Fermzilla’s sloping sides. Would have been nice to get the hops on the sides and all the yeast in the bottom, but I guess you can’t have everything.

With all this solid matter settled so nicely I didn’t want to risk disturbing it by moving the FV onto my workbench, so I decided to transfer to get straight from the fermentation fridge, using CO2 to push the beer into the keg at 10 PSI with 2 PSI differential between spunding valve and regulator. At one stage I felt guilty about using the increasingly expensive gas so wastefully and switched over to closed transfer, but by then it was 22:00 and I didn’t have time for the slow rate of flow that resulted from such a small elevation difference, so I switched back to gas.

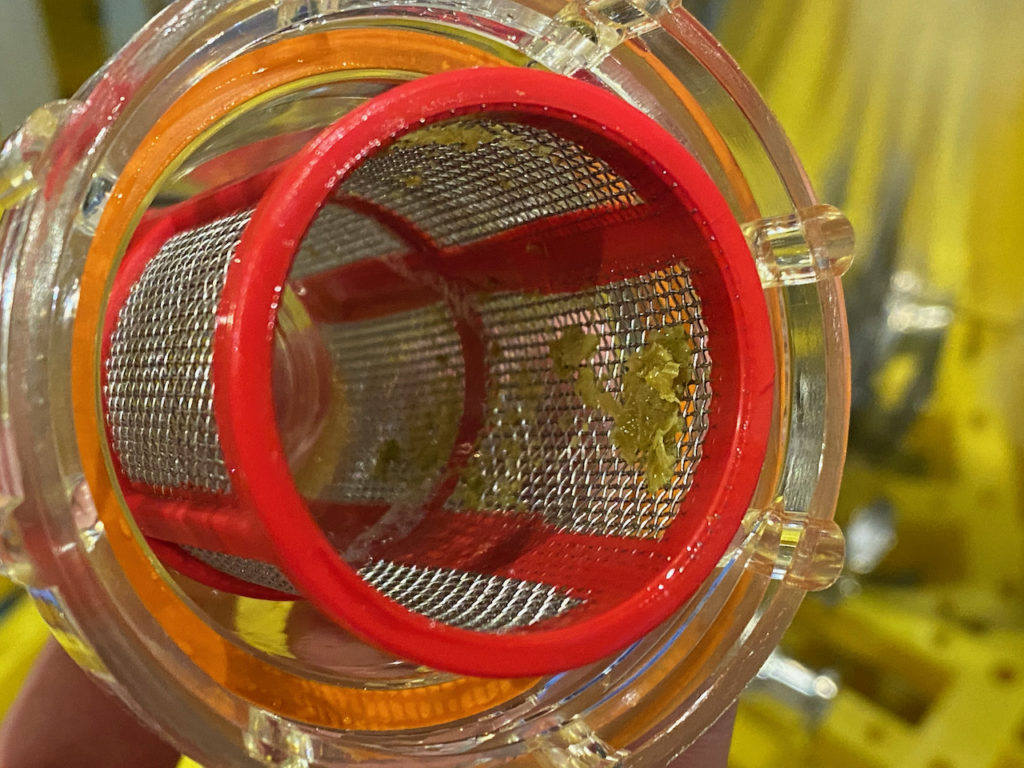

All went well until the floating dip tube touched the settled matter just below the 5 litre mark, at which point all flow ceased, and repeated clearing of the dip tube using gas failed to alleviate the problem. Later during cleaning I found a substantial wad of hops in the liquid transfer tube itself, so it looks as though this time it wasn’t the disconnect on the FV that was to blame, but regardless, I need to get into the habit of fitting a filter to the dip tube and another in the transfer tube, even if it means sanitising and purging more bits of plastic void.

In the end I gave up on the various blockages, deciding to cut my losses at 18 litres instead of squeezing out another two pints and risk oxygenating the whole keg. I knew it would be a lossy, hoppy monster and never anticipated using an overflow mini keg or even a bottle, but 3 litres of fermenter loss is quite a poor way to finish. Therefore:

#wisdom: use filters when transferring to keg. Use them. Filters.

Just put away almost a full 19 litre Corny keg plus around half a 5 litre MJ Mini using traditional gravity fed method, no purging since we’re not overly hoppy. It’s in the kegerator now on pure CO2 at about 15 PSI.

I was extra diligent at avoiding DO contamination today and flushed the 19 litre Cornelius keg with ChemSan and CO2, purged the gas transfer line with CO2, and purged the beer transfer line with beer from the FV. Half a crushed Campden tablet was also added to the 19 litre keg in order to cut down any oxidation.

The 19 litre keg was filled to around 18.5 litres, and another 5 litre keg (not purged with CO2) was filled to just over 2 litres. That second one will be my testbed to see how the carbonation gets along, and I’ve hooked them both up to pure CO2 at 15 PSI. Will check back soon to see how we’re getting along.

Very quick & dirty way of putting this to bed; open-vessel transfer resulting in several disconnect swap-outs as they became clogged with hops, ending with me just holding the silicone hose from the FV tap and dispensing into the open keg while trying not to splash too much. Oh well, at least we’re at 4.1% ABV now, pretty much like the real stuff. Putting it on CO2 in the chiller at 15 PSI, checking back in a week.

I’ve just filled a 19 litre Cornelius keg to the brim and also 2 plastic PET 1 litres bottles, using usual gravity method without filters, but this time leaving the FV in the fridge and doing it in-situ to see if I end up with less trub in the brew. Also added half a crushed Campden tablet to combat oxidation.

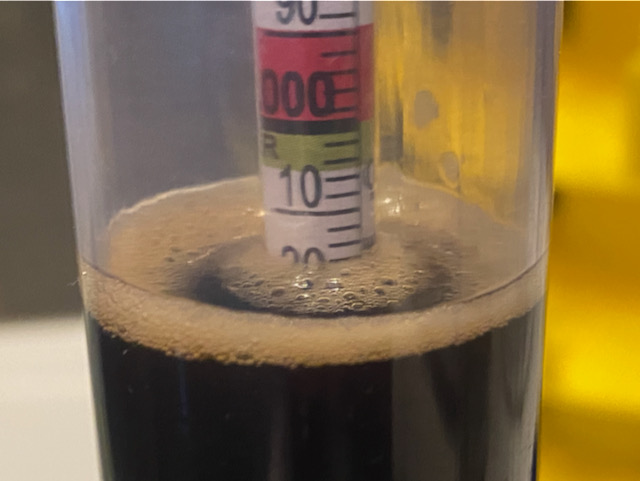

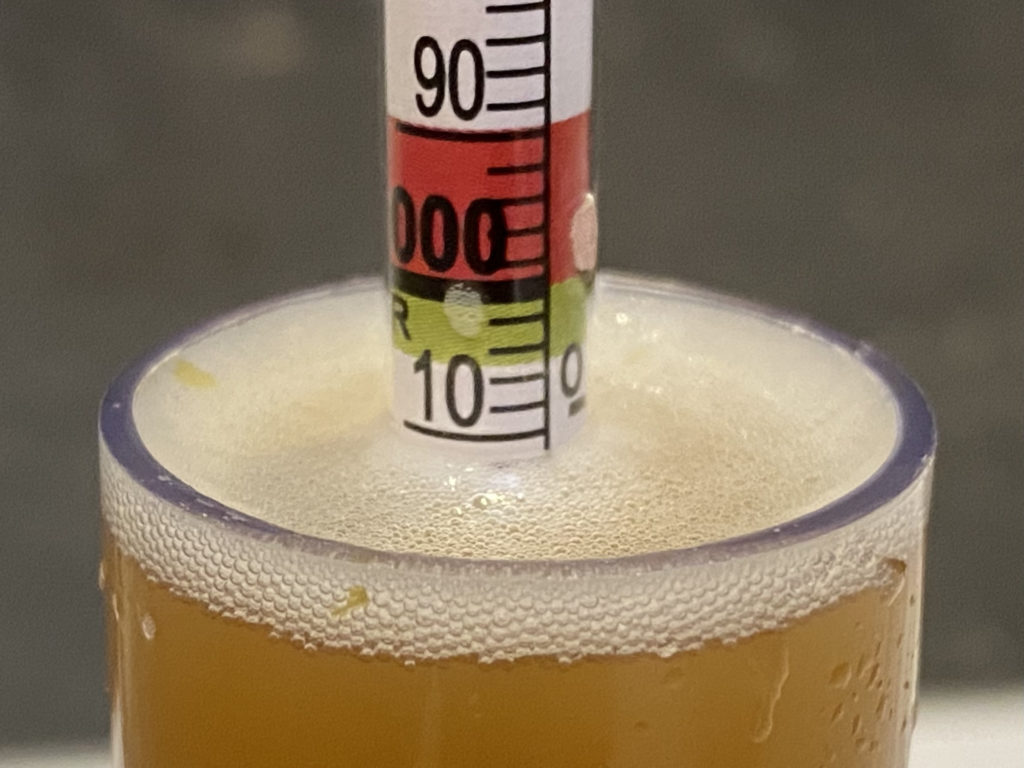

Everything went well, even if I nearly forgot about the rapidly filling keg while having a conversation on the radio. Oops! Measuring the FG was nearly impossible due to the nearly spot-on carbonation (glad I stayed at 10 PSI) but I think I’m seeing 1.011 @ 13℃ which makes for 1.010 and therefore 5.1%. There’s a fair amount of cloudiness in there despite cold-crashing so I’m going to call that chill-haze, and some lovely hop flavours from the trial jar.

What’s not great is the ABV, which even allowing for FG inaccuracy is 1.5% above where I wanted it. Could we have done with another two litres fermenter top-up? Not sure. Maybe I’ll try adding an extra 5 litres sparge water to my next recipe.

I’ve just put away 18 litres in a purged Corny keg (with half a Campden tablet, crushed) using the gravity method, and another 3 litres approximately into a 5 litre MJ mini, not purged and no SMB. There was probably another 1.5 litres still to come from the FV but the post became clogged with hop debris – might have to look at a more efficient pick-up method or install some kind of filter on the floating dip-tube. Anyway, it’s all put away now and will be allowed to condition unmolested as we’re away on holiday for a few days.

No major drama here, just plopped around 18 litres into a Cornelius keg and plugged it into 25 PSI of pure CO2 at 4℃ for speed-carbonation.

Adding this entry in retrospect because I was in a rush at the time and forgot to do it. Nothing spectacular to add really, gravity transfer from FV after cold-crashing, then into the kegerator for conditioning. I had to switch the CO2 out for 70/30 Brew-gas thanks to a supply shortage and cranked the pressure up from my usual 13 PSI to 25 PSI, but I doubt this will be enough to carbonate Yeti successfully. Oh well, at least it’s in the chiller while I think about my options.

Having gone in quite heavy on the hops for this recipe I want to make sure the flavour lasts as long as possible, and that means minimising cold-side oxidation. In addition to purging the keg before filling I’m going to have a go at adding Sodium Metabisulfite (SMB) to the keg since some people think it’s good at scrubbing oxygen. Surely worth a go? If I’m happy with the hop retention as I drain the keg over the coming weeks I may well carry out my own A/B test on a future brew. Today however I simply added 0.3g of SMB (crushed Campden tablet) to the purged keg before refitting the lid and purging it again, like the first time by slowly blowing 70/30 into the out-post with the PRV pulled for a couple of minutes.

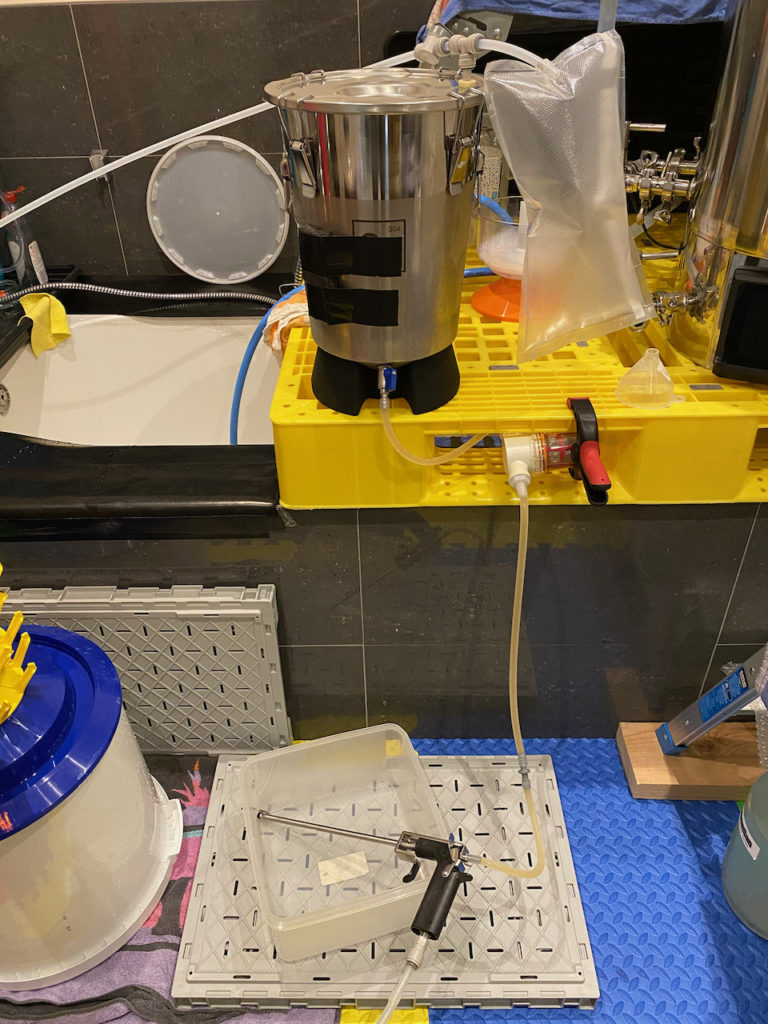

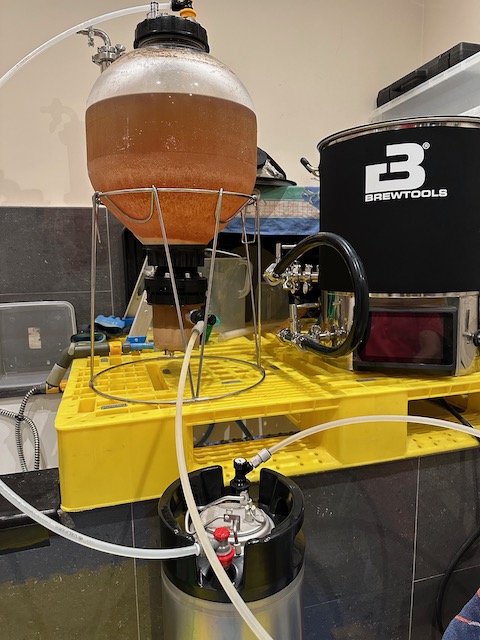

Anyway, the beer was transferred from my Fermzilla to a 19 litre Cornelius keg using the floating dip tube coupled with my finest inline filter, because it’s a double dry hopped brew and there may still be some crud transferred as we get near the end, despite the cold crashing. The filter’s barbed connections coped happily with 12 PSI of pressure on transfer, but I did have to screw the bowl on extra tight as there was some evidence of sanitiser leakage during purging / pressure testing ahead of deployment. I think this is due to the mesh cartridge being slightly too tall for the housing, or the gasket being slightly too thin – either way she wants a good hard twist to make sure everything’s sealed.

Once the 19 litre keg was filled I wanted to put what looked like almost 4 litres of surplus into a mini keg via the post on the collection jar, but although I was fairly careful the trub became disturbed using this method, and went from being settled below the take-off post to getting fairly well mixed with the rest of the brew, which by now had also picked up much of the settled hops from the sloped sides of the vessel. I was going to transfer the murky solution anyway, thinking that I can always crash it out in the keg, but for some reason the flow stopped and I got barely 2 litres. Guessing that this was due to the filter finally being clogged I just binned the rest when I really should have switched to a straight transfer tube, but during clean-up the filter actually looked pretty clear, making me wonder again if it’s worth bothering with if kegging crashed beer. Let’s make a note:

#wisdom: stop using inline filter by default if kegging cold-crashed brew, at least until a concrete reason for doing so arises.

#wisdom: if transferring FV dregs to a mini keg rather than dumping them, use a straight tube (without filter) and don’t worry about trub, which can be cold-crashed out later.

While filling the first 19 litre keg I let it run a tad too long using condensation on the side as my fill guide, and ended up with some liquid coming back out of the gas post near the end. In order to recreate some head space and also give me a sample to measure, I fitted a small tap to the liquid post and filled my trial jar, setting it aside while cleaning up in order for the foam to settle. Even so it was difficult to get a decent reading, because dropping in the hydrometer caused more bubbles to rise in the carbonated brew. Maybe I should have chilled and wetted the hydrometer first? Anyway, I measured a FG of 1.008 (very approximately) at 16.9 ℃ which makes for 1.007, and 5.6% ABV. Happy with that, and extremely happy with the hoppy taste from the trial jar. Let’s hope the SMB does it’s job and we get to enjoy this one for weeks to come!

I’ve just put away around 22 litres using basic gravity transfer method under pressure. We filled one 19 litre Cornelius keg and half a 5 litre MJ Mini. Applying 12 PSI of CO2 in the serving fridge for a couple of weeks to condition her properly, then I’ll rack to another vessel and it’s off to the party.

I put away a full 19 litre keg just now, with some left over in the fermenter but not enough to significantly fill a spare 5 litre keg. Got about 1 litre in there nevertheless, which I’ll drink later after checking gravity.

Taste is quite hoppy with no funk (I’m sampling the dregs at 13℃) and it comes in at 5.5% ABV. Can’t wait to see what this tastes like after another week in the chiller, if it’ll last that long. Pressurised to 12 PSI at 4℃ and awaiting conditioning.

Standard procedure: gravity-fed line from SS Brewtech stainless bucket to liquid in post on Cornelius keg, pop the PRV, wait 15 minutes. Stick it in the chiller, pressurise to about 12 PSI. Wait.

We just filled a 19 litre Cornelius keg until foam started coming from the airlock, but it was mostly sanitiser. Reckon there’s about 18 litres in the 19 litre keg, give or take. The rest went into a 5 litre MJ Mini, stopping again at the foam-in-PRV stage. Maybe 1 litre left in the Fermzilla that went to the fishees.

Forgot to take FG reading so we’ll try to remember when it’s done conditioning in a couple of weeks’ time.

There’s no more visible activity on this one so I’m putting it into a 10 litre mini keg along with 200g Xylitol, gassing to 15 PSI. Forgot to measure gravity so let’s run with Tilt values; 0.996 / 4.84%, 21.1 ℃.

It’s been cold-crashing for a couple of days, time to put this redundant Blonde into a keg and get ‘er drunk. Transfer method was the usual quick & lazy connection of both liquid out posts with a spunding valve on the keg and around 8 PSI going to the vessel from my cylinder. I filled approximately 18 litres into a corny keg and 2 litres into a 5 litre MJ mini. Off to the serving fridge at 10 PSI – will measure gravity later as I’m in a rush.

Having cold-crashed for a couple of days it’s time to put this one away and free up the fermentation fridge for my next effort. Not much to report really, I just let gravity do the work and trickled the brew from the SS Brewtech Bucket to a 19 litre Cornelius keg, airlock removed in the former and PRV prepped open in the latter.

On a positive note it seems I had about 17.5 litres in the fermenter and there was only about 1 litre of gunk settled in the bottom, which is where it stayed. On a negative note I measured the FG at 1.016, and that’s being optimistic, so looking at about 7.4% ABV this time around.

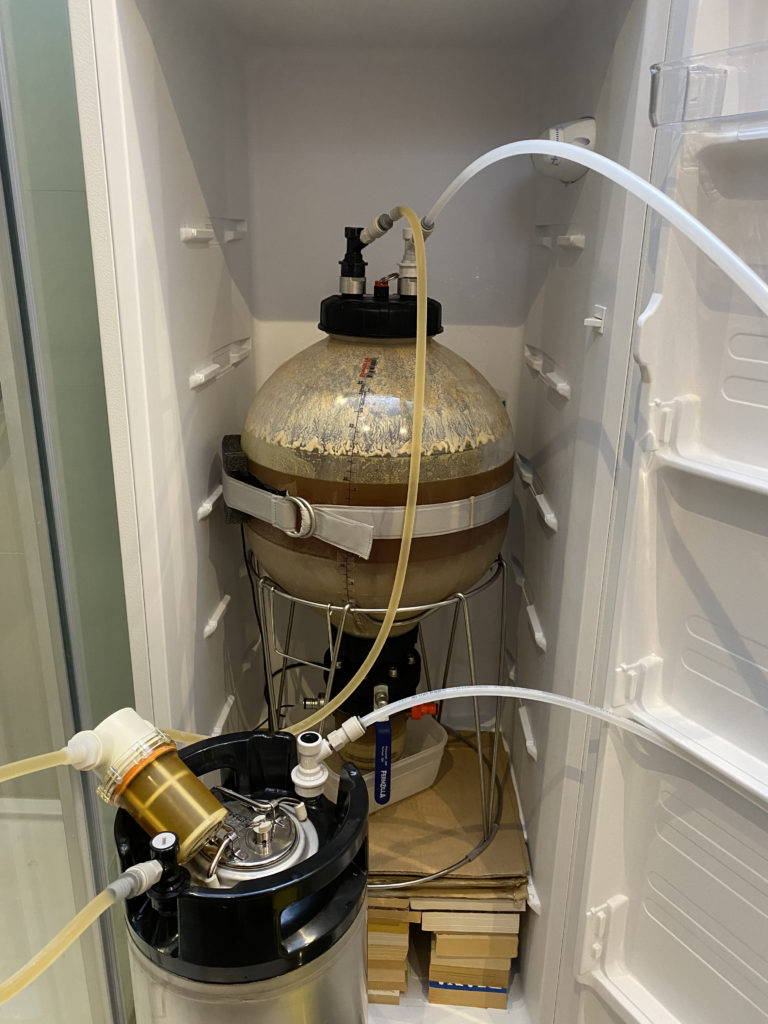

I’ve been itching to get this put away for a spot of conditioning for quite a while now, but with no kegs (or kegerator) space available she’s just had to carry on cold-crashing in the Fermzilla for a bit longer – 2 weeks in total now.

Out with the Old…

Well, today I eventually drank the last foamy pint of Good Night Vienna, crammed 2 pints into a PET bottle, and chucked out the remaining one or two pints just so that I could free up a 19 litre Cornelius and put away Sarka before going across for a week. Yep, you read that right – I dumped actual beer just to free up a keg, that’s what it’s come to now. To be honest though I’d had enough of the over-carbonated not-quite-lager not-quite-malt style. Going forward I’ll only do this one again in smaller volumes, maybe a 10 litre keg plus a couple of bottles. And I’ll better calibrate my beer lines; the tap that GNV was on is the last one to receive a coiled length of 3/8″ and with just a short length of 5/8″ between the keg and the tap there was way too much pressure for such a short run.

In with the New …

Not much to add here really. It’s late in the day and I couldn’t be bothered to rig up a gas balancer line or transfer filter (should be all clear after a fortnight at 1℃ anyway) so I used a straight liquid-to-liquid line and spunding valve on the recipient keg, transferring at 10 PSI with 9 at the keg and in order to keep the foam down. Filled one 19 litre Cornelius and one 5 litre MJ mini, the Corny went straight back into the kegerator at 10 PSI and the mini’s in the spare fridge. As always, fingers crossed.

Both my 19 litre kegs are in use, so I’m putting this away as best I can; 1 x 5 litre MJ Mini, 1 x 10 litre MJ Mini, 6 x 500 ml yellow crown cap bottles. The 10 litre keg is going straight into the kegerator at 15 PSI serving pressure and should be carbonated in about a week. I don’t have a spare line for the 5 litre keg, so I’m cranking it to 35 PSI and sticking it in our main fridge, complete with pressure gauge to let me know when it needs more gas.

The excess beer from this operation went into 6 x 500 ml standard crown caps along with 5 ml of dextrose, and now they’re in the server room for about a week. FG looks like 1.009, which means that this, my third incarnation of Bure Gold, comes in at 5.0% ABV – quite a bit above the standard 4.2% with included yeast as per my previous two brews. Can’t wait to see if there’s any difference in taste.

Keg Business as Normal

Standard story here with no drama; began as a closed loop pressure transfer at around 5 PSI (had dropped from 15 to 5 during cold-crashing) and filling a 19 litre Cornelius keg via floating dip tube to liquid-out post. After a while I grew bored with the trickle of beer from one vessel to the other so I junked the gas line and rigged the Fermzilla straight to my CO2 cylinder while popping the PRV on the keg now and then.

Bottling Carbonated Beer

There seemed to be between 23 and 24 litres in the Fermzilla, so having filled a 19 litre Corny keg I decided to try something I’ve been thinking about over the past couple of weeks: getting the remains into some bottles without making an almighty mess. Turns out that it’s not too hard at all, provided you have some threaded PET plastic bottles and a spare carbonation cap. Simply pop the liquid disconnect off the Corny keg once its full, and whack it onto a carbonation cap fitted to a plastic bottle. Originally I wanted to use the plastic T-piece on my bottles because that would allow me to have dedicated liquid and gas posts – just like a keg – but I was down to my last carbonation cap and therefore had to use it for liquid, venting out gas to keep the flow going by unscrewing the cap a few turns.

It worked pretty well, and although I pre-ressurised my first bottle so as to match the keg and minimise foaming via the dip tube on the bottom of the cap, by my second bottle I’d forgotten to do this and it didn’t seem to make any tangible difference. In the end I filled two and a half 1 litre bottles with practically no mess, unlike those tap-mounted counter pressure fillers you see now and then. The only downside is that when removing the carbonation cap after filling a bottle it effectively vents the headspace to atmosphere before the plastic cap is fitted, which may affect carbonation, and the exposure to oxygen may lead to oxidation too. Don’t care – with no way to carbonate these plastic bottles any further I’ll just have to drink them fresh while the keg matures, which is something I can live with.

Closing Thoughts / Wisdom

- The distribution of finishing hops this time around has been much better than during Twisty Listy. I don’t know if this is due to me being a bit more violent when releasing the butterfly valve during dry-hopping and having everything slosh around, or if it’s a consequence of using Kveik yeast which led to a resurgence of ‘boiling’ fermentation once the finishing hops were added 9 days ago. I do know that the presence of hops is very prevalent on the palate and in the nose, something I’m very pleased about, especially with just 50g added. No worries here at all.

- Since I had carbonation caps fitted to the collection jar from purging the finishing hops, I thought I could cheat the floating dip-tube and collect some more beer by moving my Bouncer filter to the lower post. This turned out not to be the case, because despite the trub being lower that the post initially, as I drew liquid down I also caused some of the hops that had settled on the Fermzilla’s sides to slide down, which led to the carbonation caps becoming blocked. I ended up putting my line back on the floating dip-tube to finish off.

- The Tilt Pro continues to perform admirably, surviving pressure changes as well as cold-crashing. In fact the only sign of moisture inside is when I stupidly took it out of the chilled trub and washed it in warm water, causing some condensation to form in the top. Still, nothing on the batteries and circuit board, so I’m leaving it sealed.

Pressure transfer to Cornelius Keg

The Fermzilla version of this one’s been cold-crashing for 3 days now, time to get it into a Corny keg. Standard setup this afternoon; brought the ready purged keg up to 9 PSI matching the Fermzilla, connected the Bouncer filter between the liquid out posts, popped the PRV on the keg to get things going before connecting the gas posts with a straight line. I left the Fermzilla in the fridge the whole time, and there was enough height difference to the keg for gravity to do it’s thing, filling it in around 20 minutes.

I’m not 100% convinced I need the Bouncer filter when doing a pressure transfer via the floating dip tube as that doesn’t really pick anything up, especially on a cold-crashed beer where everything’s well and truly dropped out. If anything, the Bouncer is a bit of a pain as it doesn’t handle pressure too well and is just one more thing to clean at the end of the day.

15 Lager Bottles

The 5 litres or so that I moved to the SS Brewtech Mini Bucket ahead of applying pressure to the Fermzilla has been bubbling very, very slowly while it’s sister vessel was cold-crashing, so I’m going to call time on this one and also put it away. This time I used Bag-Thing on top (but forgot to refill it) and added 1.5g of Dextrose to each of the 15 clear lager-style 330 ml bottles before filling those via the bottling wand and tube attached to the bucket’s lower spigot. I started out by also priming the first bottles with CO2 from the cylinder, but noted that on drawing out the wand I will have sucked air back in as the level went down, so I gave up on the CO2 figuring that there’s no finishing hops to be oxidised anyway, and that the reaction of beer on dextrose did produce some gas which had the caps lifting a little while they were waiting to be fixed.

Some Gravity

Even though I kegged the Fermzilla first I set it aside before measuring OG, and instead bottled the SS bucket then measured OG there from the inch or so that was below the dip tube. The brew bucket came in at about 1.017 and when I got around to grabbing a sample from the Fermzilla’s collection jar I thought there was a discrepancy, because that weighed in at 1.019 to 1.020 – difficult to say due to carbonation. It soon dawned on me that I was seeing a difference because the Fermzilla was still at chiller temperature, so anywhere between 4 and 6℃. Plugging those values into Brewfather’s hydrometer temperature correction tool soon had my numbers lining up.

Pretty straight forward kegging / bottling session today; filled the 10 litre MJ mini keg and 14 x 330 ml Steinie bottles with black caps. I left Bag Thing attached from cold-crashing as I moved the 25 litre SS Brewtech bucket out of the fridge and plumbed in a T-piece so that I could feed in CO2 from the keg as it filled and wouldn’t need to keep topping up the bag from my cylinder in order to prevent oxidation. The plastic bag acts as a great buffer in this respect and prevents any vacuum locks – not that I think O2 elimination is particularly important for this brew, but good practice all the same.

Once the keg was filled I plumbed in the Beer Gun and started to fill some Steinies, 4 at a time primed with 2.5 ml of Dextrose using a baking spoon and putting on a sanitised black crown cap as soon as the final blast of O2 was deployed. I’m sure I had about 18 litres in the fermenter and as 10 of those were kegged there should have been 24 Steinies to fill, but I only got 15 from what was left. To add insult to injury I had to chuck one of those away between capping and warm-conditioning as I noticed cracks in the upper neck of the bottle due to a manufacturing defect. Best not to risk an explosion or internal injuries from glass shards. Tough call though.

On a positive note I did recoup some yeast using a sterilised (boiling water) spoon and a sample tube which was from a batch originally purchased for Geocaching purposes. There was easily enough for another 1 lb honey jar in the bottom of the FV but I only grabbed enough for a small vial, reasoning that I’d probably use all of that to make a starter so there should be enough.

Finishing hops were added two days ago, time to get this into a couple of kegs and some bottles! I used my original bottling cane throughout, filling one 5 litre mini keg followed by as many bottles as I could, then repeating the process for the other variant. Managed to package 15 bottles in total;

- 7 black crown caps of dry-hopped ale, and

- 8 silver crown caps using Hot French Randall.

The dry-hopped ale went first and looked as well as smelled like you’d expect, but the HFR variant had practically no aroma at all, and when I tasted some it reminded me of a traditional bitter rather than a pale ale. To be fair it was warm, young and not carbonated, but I was hoping for some more hoppiness right from the outset. I had a quick taste of the dry-hopped variant too, but that was from the slops bucket where I’d primed the racking cane, so there may have been a trace of sanitiser mixing things up. Still, I’m almost tempted to say it tasted better than HFR, but that would be unfair.

The bottles are now up in the server room digesting the 5 ml of dextrose that was added during bottling, along with a pre- and post-fill blast of CO2 from the line, because why not. Let’s give them a week in the warm before turfing them out to the garage for conditioning.

Both kegs meanwhile are in the beer fridge, temperature somewhere between 5 and 7 degrees, pressure cranked to 13 PSI since I’ve also got Twisty Listy in there and want to enjoy that without a foam party on each pour.

Put away between 22 and 23 litres today, mostly filling a 5 litre mini keg and a 19 litre Cornelius. No real drama as such; this time I remembered to flush the filter line with CO2 after sanitising it and again I did the same with both kegs, so I’m looking forward to a really hoppy number with no oxygen contamination. Again I used the fully-closed system, feeding CO2 from the keg back up to the fermenter once I’d popped the PRV to get things going, but this time I didn’t drop the pressure in the Fermzilla (which had gone from 7 to 12 PSI since dry-hopping) instead matching it by increasing the keg to 12 PSI also.

On the subject of filters, I’m using the Bouncer again but this time with the finest mesh, which I had to order specially. It kept behind a fair bit of hop matter but we’ll have to see how good it really is when I draw off the first pints from those kegs. Admittedly it’s not going to be a true representation of the filter’s ability since I didn’t cold-crash the Fermzilla this time, so I expect there to be a fair bit of crap in the bottom of each keg just from crashing. One final note where the filter’s concerned, and I’m not 100% happy with the fit of the replacement element, it’s just very very tight and ended up being skewed slightly when I screwed the filter closed. Will have to see how that works in the long run – might be OK, might be its first and last outing.

One thing that was slightly disappointing (or rather it will be) is the hop utilisation, which I’m guessing is going to be nowhere near what I want. When I removed the collection jar at the end of transfer there was an almost solid green lump of lovely hops in there, full of gorgeous pungent aroma. They even stayed put when I turned the collection jar upside down, so how on earth have they imparted their goodness unto my brew? Maybe dry-hopping is better for flat-bottom fermenters, maybe there’s a reason after all why so many stateside brewers rack to secondary. I don’t know. I do know that I’m going to try the Hot French Randall (HFR) method a go next time around, and have ordered a 1 litre double walled cafetière specifically for this purpose.

Another thing I’m going to have to order is a new collection jar for the Fermzilla. After I tipped out the semi-used hops I reassembled it loosely in order to soak it in PBW, and I forgot the manufacturer’s advice about not using the two ports for leverage. I’m not normally too ham-fisted and like to think I’ve got a good level of mechanical sympathy, so I was rather surprised when one of my stainless carbonation caps came off in my hand, taking a chunk of plastic with it. Oh well, live and learn.

Took just over 24 hours to get from room temperature down to 4.0 ℃ in the brew fridge. I had that dialled to ‘med’ for the first half and then just below ‘max’ for the second as I didn’t want to freeze the 19 litre keg of Golden Wave that was already in there, nearing the end of it’s conditioning phase. Three days later I’m ready to put this, my third extract brew, into final packaging.

I don’t want to tie up both 5 litre mini kegs and also put some bottles away to share, so it makes sense to try and guess the number of bottles I could fill while also using as much of one keg as possible. In the end I went for 8 x 500 ml silver crown-caps and hoped for a nearly-full keg to allow room for carbonation, but realistically kegged somewhere between 3.5 and 4 litres.

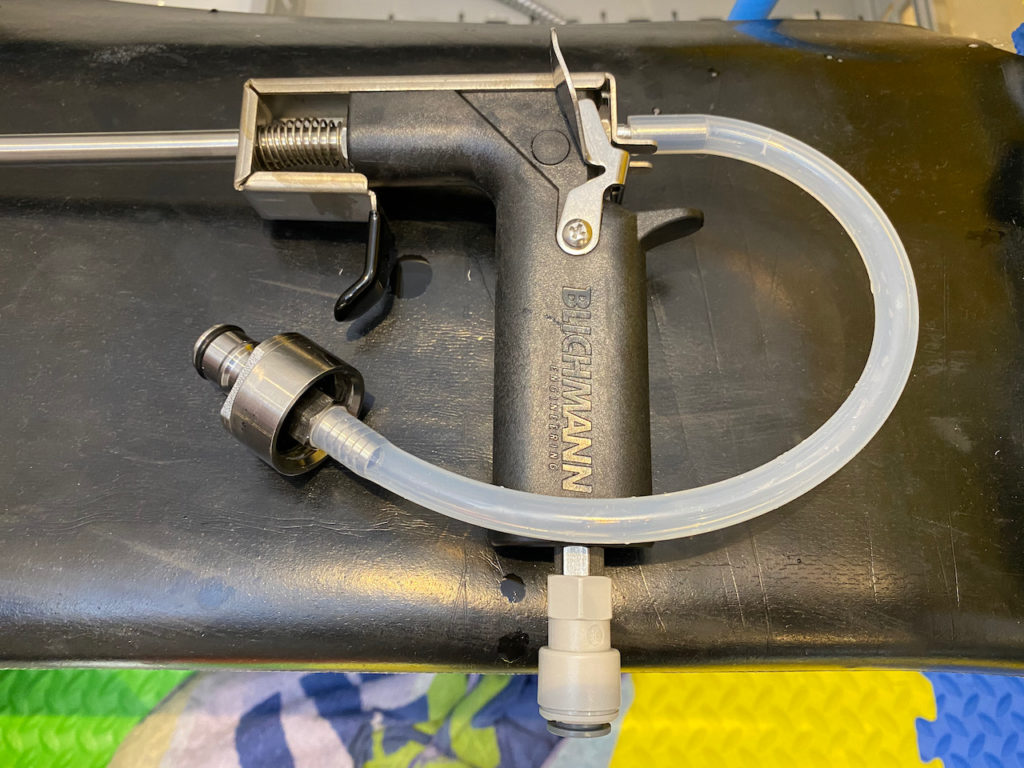

For the bottles I used the Blichmann Beer Gun again, and thinking about it this may have been it’s first outing with actual beer. I set the SS Brewtech Mini Bucket onto the lab platform (plastic palette over the bath) and relied on gravity to pull liquid through my Bouncer filter from the bucket’s spigot and into the beer gun. Even with this modest drop in elevation the flow was enough. Gas was routed to the beer gun via one ⅜ line with another feeding Bag Thing on top of the bucket behind a John Guest tap and T-piece. Absolutely no flaws in setup here; both gas and liquid being delivered efficiently even if I did forget to purge the filter with CO2 before starting. Oops. Each bottle was primed with 5 ml of dextrose – conveniently using a baking measuring utensil I found in the kitchen. Hopefully it’s near the 3.3g that I need for 2.4 vols, according to the calculator. She’ll be right.

Once bottling was done I was about to start rigging up the necessary equipment to fill a 5 litre mini keg with sanitiser and then flush it with CO2 when I realised that, actually, this is just a really big bottle which will get drunk as soon as it’s carbonated in a week’s time. I still had the beer gun set up for bottling so I just used that, giving the keg a decent blast of gas and then filling it until I started seeing bubbles coming from the bucket. I couldn’t remember how low the dip tube was set and was keen to try my new filter, so I gave the spigot a clockwise turn until it started drawing liquid again. One or two lumps could then be seen making their way towards the Bouncer but not beyond, so I kept fiddling with the spigot until no amount of turning would result in more beer. That’s eight bottles and almost a 5 litre keg. Nice one!

After spending a day in the cold I’ve decided that not much more is going to drop out of this beer, so it’s time to hit the keg and free up the fermenter for my next concoction. There being just under 22 litres in the Fermzilla I opted for a fully closed transfer to a 19 litre Cornelius keg and the rest into bottles, and it almost went without a hitch.

Starting a fully closed transfer was as simple as connecting the liquid out posts of the two pressure-balanced vessels with my newly rigged transfer line (2 bits of silicone hose and a large Bouncer filter) and then briefly popping the PRV on the lowered keg in order to start the syphoning process. As soon as beer is in motion the two gas posts were connected with a straight pipe between two disconnects – simple. Naturally the keg was purged of air beforehand by filling it with sanitiser and then pushing that out with bottled CO2, doing the same with the filtered beer line and also flushing the gas line in the process.

I initially gave both the Fermzilla and the keg just 5 PSI because I didn’t want to risk blowing the silicone hose off my filter’s barbs, but increased it to 12 PSI when I noticed that the piece of hose downstream from the filter was ¼ full of tiny bubbles which I first took to be an air leak despite the enthusiastically tightened plastic union. Seems that it wasn’t an air leak but carbonation escaping my beer as it rushed through the filter, and increasing pressure back to serving PSI fixed that.

Using the Blichmann Beer Gun was less successful, largely because even the slightest bit of pressure caused beer to squirt out of the muzzle due to the design of the silicone bead at the end. To get any level of control I had to purge the Fermzilla of pressure entirely and rely on gravity to dispense the already carbonated beer, which wasn’t nearly as clean as it sounds and resulted in just two bottles filled, barely justifying the amount of cleaning that was necessary afterwards.

Ending on a positive note, I rigged a clumsy arrangement of silicone and carbonation cap so that I could use the beer gun with the same transfer line as I’d used for the kegs, which was relocated from the floating pick-up tube to one of the posts on the Fermzilla’s collection jar. By a happy coincidence the level of settled trub was just below this post, and I was able to draw quite a bit more beer than the floating dip tube would have given me.

I’d like to say I’ll use this method again, but chances are that if I’ve used the Fermzilla then my beer will be at least partially carbonated by the time it’s ready to bottle, and unfortunately this really isn’t the beer gun’s strong side. Nice try though.

After eight days in the chiller it’s time to put this one away, and I decided to fill one of my 5 litre kegs with the rest going into bottles, hopefully letting me form a comparison not only between this brew and my first extract blonde, but also between keg and bottle versions of the same batch.

Eliminating Oxygen

Keg or bottle regardless, I was keen to prevent as much oxygen from getting at the beer as I possibly could. Bag-Thing was already rigged up to the mini bucket while it cold-crashed in the fridge (used between ¼ and ⅓ of a filled bag over the week, for the record) so it was just a matter of topping up the carbon dioxide bag as I drained the beer. This was easily achieved by fitting a John Guest splitter between the bag and the bucket and splicing it to the CO2 regulator so that it could be manually topped up as needed.

Before I started drawing off beer into the keg I wanted to make sure that my dip tube wasn’t about to suck up dead hops and other trub, which took some leap of faith since I had no way of telling how much was in there and nor any means to filter the output. In the end I decided that cold-crashing should have settled everything as much as it was ever going to be settled, so I rotated the dip tube to its highest setting by turning the spigot clockwise – a neat feature to have.

But I still didn’t know if the tube would be clear of the sediment, so the only way to find out was to fill a cheeky tumbler. Immediately I started getting bits of hops but the stream soon cleared up, must have just picked up some random particles while adjusting the tube. The beer wasn’t anywhere near as clear as Bure Gold – the first one I ever cold-crashed – but then again that was too was cloudier during kegging than nearer the end. This did however taste wonderful, not as bitter as the first extract attempt and with slightly more hop punch. Time for one last check of the bag setup and let’s get it done.

Kegging from the SS Brewtech Mini Bucket

Once I was confident that no oxygen would enter via the top, putting this into a sanitised & purged keg was as simple as connecting a piece of silicone hose from the elevated bucket’s spigot to a barbed beer disconnect and popping the pressure relief valve now and then. That last step grew old very quickly so I fitted a gas disconnect as well and just kept topping up the CO2 at the bag end while the keg vented it to atmosphere. I realise now that with the bag being such an effective buffer I could easily have used the extraneous gas from the keg to top up the bag and made for a truly closed loop – definitely something to try next time.

I used the “cold finger” method again and left the keg with about 2 inches of head space before pressurising it to 30 PSI and putting it in the chiller. I’ll reduce this gradually after 3 or 4 days to 10 PSI serving pressure, hopefully that should then be ready to sample.

… and now Bottling

I really wanted to use my Blichmann Beer Gun to continue the oxygen-free theme but there was one small problem: I needed the JG 2-way splitter in order to provide the gun with gas, but that piece was in use by Bag-Thing. (sorted for next time: an adapter is on the way)

To overcome the equipment shortage I temporarily borrowed the CO2 supply and crudely purged some clear flip-top bottles by flushing them with carbon dioxide after I’d dropped in two carbonation drops in each, targeting 750 ml. Yes, overdoing it a bit there, but those drops were all I had left and I couldn’t be arsed to mess about weighing out loose dextrose for the sake of a couple of bottles. Once they were gassed and carbed it was easy to rest the flip-top stopper on the mouth of the bottle until each could be filled via the same silicone tube I used while kegging, just without the disconnect attached.

All this went fairly well until I started drawing bubbles halfway into the first bottle – guess that dip tube must be quite long after all. Seeing bubbles during filling is never good, but I kept telling myself that it should be OK since the bottles were filled with CO2, and it’s better to splash some gas about than set the tube too low and draw in unwanted rubbish. This method of constant adjustment saw me filling four 500 ml clear flip-tops while lowering the dip tube gradually before I hit the hops on the fifth bottle.

While cleaning the vessel after bottling I noted that the trub-line was roughly equal to the conical part. Obviously this will vary wildly depending on what’s added to the brew during fermentation, but it’s good to have this guide and reassuring to know that there’s quite a bit of adjustment on the dip tube – the guys at SS Brewtech have clearly done their homework.

In closing, one thing’s just occurred to me: by cold-crashing before bottling I may have removed the yeast that I need to turn my carbonation drops into carbonation. If these turn out to be flat then I need to learn from this, and draw off that part of the batch which is to be bottled before cold-crashing. As always, fingers crossed …

#wisdom: cold-crashing the mini bucket for a week uses between ¼ and ⅓ of a filled Bag-Thing, no need to worry about having to refill it partway.

#wisdom: if filling a purged keg from the brew bucket, use the gas that’s being driven out of the keg to refill the bag on top of the bucket.

A late session today saw me putting away the S&B cider 7 days after starting primary. The flavouring was added 24 hours ago so it’s too late to worry whether or not I should have left it for another couple of days, time to get it packed.

I started by taking another gravity reading out of habit, although I suspected it might be invalid with all that flavouring in there. Wasn’t disappointed – she registered 1.013 which I’m taking as additional non-fermenting sugar (i.e. the sachet of pear and strawberry flavour concentrate) combined with no further fermentation of what was already in there. I’m therefore recording the reading of 1.013 on this log but using 1.011 from yesterday as the final gravity, producing 5.25% ABV against an expected 4.7%. Had we made it all the way to 1.007 we’d be looking at 5.78%. Yikes!

All Change

With the sample taken it was time to set up the racking cane / auto syphon as usual, and while doing so I decided to do two things differently this time: fill one of my small kegs and carbonate with CO2 in order to see if it impacts the taste compared to primed bottles, and try out my new Blichmann Beer Gun on its first bottling run.

I cleaned and sanitised a 5 litre mini keg but didn’t bother purging it with Star San and then CO2 as I would while doing a closed transfer from the Fermzilla, as there seemed little point in trying to keep oxygen out when racking from an open bucket. Instead I filled it to within a couple of inches from the top using the bottling cane and then cranked it to 30 PSI before popping the PRV a couple of times (may as well get some oxygen out) and putting it in the fridge next to my other 5 litre keg containing the last of my Bure Gold. Time to try out that Beer Gun.

A Small Error

A cursory glance at the new gadget showed it came with a black disconnect, so I started by racking the remaining cider into a clean 19 litre Cornelius keg using the still connected bottling cane. It looked to be around 17 litres and since I was almost out of carbonation drops I decided to weigh two of them, the recommended dose per 500ml bottle, and multiply the resulting 5g by 17 to tell me how much dextrose I need to add. That was around three hours ago, and it’s only now that I’ve pulled up the Beer Priming Calculator in order to see if my quantity of priming sugar tallies with Brewer’s Friend that I’ve spotted the mistake: there’s two bottles per litre not one. I’ve therefore added half as much as I should have, which explains why Brewer’s Friend recommends 160g of Dextrose for a fruit lambic – about the closest to cider in my opinion. Oh well, looks like it’ll be a slightly sparkling cider this time around.

That was three hours ago and I carried on in blissful ignorance, adding the sugar to the Corny keg as the bucket emptied. Once I had all the cider I was going to get from the bucket I capped the keg and hooked up the gas, again popping the PRV a couple of times in order to dump some oxygen from the top of the vessel. The beer gun was quickly taken apart for inspection and sanitation, and I saw the first problem: the gas line was designed to screw onto a male regulator post, which I didn’t have. I did have a John Guest T-piece and some more beer / gas line, so I used that instead of the gas line that came with the beer gun. Not ideal since it’s quite stiff and made the process unnecessarily cumbersome, but I was determined to try it out.

Ready … Aim …

Once back together the beer gun worked very well, letting me purge oxygen from each bottle before filling it to the top and purging some more while drawing out the nozzle, then capping straight away. I think it’s a very slick tool and once I’d cranked up the pressure to around 15 PSI I was able to fill bottles at a good rate, though doing this with partially carbonated beer straight from the Fermzilla might require a bit more experimentation as there’s bound to be some foam, whereas the cider was totally placid. Might end up using a fair bit of gas though, so perhaps reserve it for ultra-hoppy beers?

Then again, this is the first bottling run following my first kegging session, and I’m inclined to agree with everyone who sings the benefits of kegging thanks not only to the superior taste of draught, but also due to the simplicity and speed of the kegging process compared to cleaning bottles, filling them while watching out for oxygen, capping them, and washing up afterwards.

And if you cock up the carbonation it’s as easy as cranking up the regulator.

I just kegged my first ever brew!! Everything went very smoothly and exactly as planned, so I’m now going to leave it alone for a week or two in order to settle down. There are around 17 litres in a 19 litre Cornelius keg, stashed in my new brew fridge which has become available since I’m no longer cold-crashing.

I’m not really sure what to do in terms of carbonation pressure. The dregs I sampled at the end of today’s fun and games was pretty much spot-on and that’s after a week or so at 10 PSI, so I don’t think I need to give it much more. I’ll pump it up to 12 PSI once the keg has acclimatised just in case there’s a slow leak somewhere. There’s no gas inside the fridge since chilling a cylinder seems wrong and I’ve not explored the drain hole method (ooh-err) though I’m leaving the spunding valve & gauge connected so that I can check on the pressure just by opening the door. If there is any drop in pressure I’ll remove the spunding valve and will rig the gauge straight to the disconnect, if it drops after that I’ll take everything off and will just leave the keg to it, checking in a day later.