That’s it, my second NEIPA is all finished, more or less to the day that the third version is ready to be tapped. The hop flavours in this one did fade predictably towards the end but it remained drinkable until the last, and was just starting to clear up, with quite a lot of settlement in the bottom of the keg at clean-up time. Definitely can’t move this type of brew if and when I come to put some in bottles.

Geronimo

| Ref | 2022-10 Geronimo | Brewer | Pain & Patience |

|---|---|---|---|

| Style | New England IPA | Type | Beer, all-grain |

| Started | Tue 25th Oct 22 | Status | Archived, |

| Packaged | Sun 6th Nov 22 | Fermenter | Fermzilla |

| Handle | 2022-10 Geronimo |

|---|---|

| Brewer | Pain & Patience |

| Style | New England IPA |

| Type | Beer, all-grain |

| Fermenter | Fermzilla |

| Status | Archived, ABV |

| Started | Tue 25th Oct 22 |

| Packaged | Sun 6th Nov 22 |

Put away a full keg plus two sample glasses from an indicated 21 or 22 litres. The new filter on the floating dip tube worked well and there was no clogging, with minimal sediment in the last two glasses pulled.

I’m undecided whether or not to fit a second filter to the collection jar. Standard practice ahead of cold-crashing now is to almost close the butterfly valve on the mostly spent yeast that’s collected below, so that the finishing hops don’t all fall into the same pit, and that the exposure to spent yeast is limited. This seems to work well, with any subsequently settling hops staying out of the jar and falling onto the Fermzilla’s sloping lower sides.

The upshot of this is that there appears to be some clear liquid above the yeast in the jar, and I’m wondering if I can tease out another couple of litres instead of losing between 1.5 and 2.5 litres to trub on each transfer. The answer is probably not, for what transpired to be reduced dip-tube final mobility thanks to adding the filter actually turned out to be the filter coming to rest on a bed of hops atop the butterfly valve, in which case we won’t be pulling much liquid down via the secondary filter anyway. Still, might give it a go next time around.

It’s unusually warm at nearly 30℃ so may take a while to get down, and I’m wondering if there’s any danger to the equipment on account of such a large drop. Glycol chillers do have a maximum chill threshold, hopefully this won’t knacker my fermentation fridge. Inkbird set for 1℃ at 13:00.

The fermentation curve has levelled out and there are just a few bubbles in the dip-tube every couple of seconds, so now feels like a good time to get my finishing hops in while there’s still a smidge of activity to guard against oxygenation.

With that I added a great big bag of assorted hops as per recipe, also fitting the newly arrived filter to the floating dip-tube. Hopefully when it comes to transfer we’ll get a little more across than last time before the disconnects clog up with green goop.

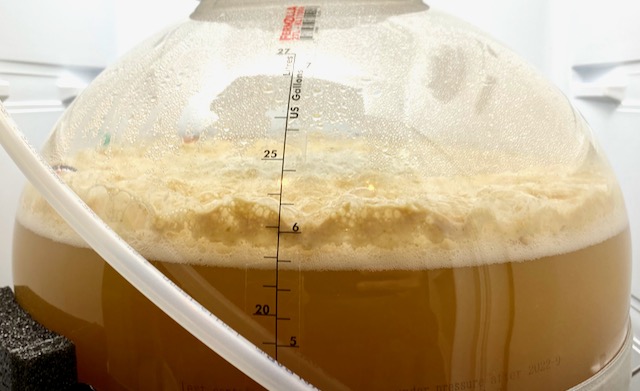

I believe I was right to attribute yesterday’s initial bubbling of the blow-tube to temperature expansion since there was no sign of foam, but this morning’s a different story, with a nice cake of healthy krausen sitting on the FV’s surface just 18 hours after pitching.

The blow-off tube is popping constantly and the spunding valve has settled on exactly 5 PSI and is hissing quietly. I’m wondering if 5 PSI is enough to suppress some of the yeast’s desired character so maybe we’ll try one without pressure at some point, but for now I like the head start on carbonisation and prevention of O2 ingress during cold-crashing.

We’ll see where it goes. Looking good for now.

Great brew day today! Following a discussion with Brewfather’s creator I decided to increase the Grain Absorption Ratio in my equipment profile from the preset 0.8 to 1.2 in order to tame my mash losses, and now my volumes are bang-on where they should be. The extra water is added to the sparge amount, and when my initial increase to 1.0 only added around one litre I decided to up it to 1.2. Here’s how that compares to my previous go at this brew:

| Geronimo 1 | Geronimo 2 | |

|---|---|---|

| Grain Absorption Ratio | 0.8 | 1.2 |

| Mash Water | 22 | 22 |

| Sparge / HLT | 9.71 / 11.41 | 11.71 / 13.41 |

| Total Water | 33.41 | 35.41 |

| Mash Volume | 25.35 | 25.35 |

The upshot of this change was that for the first time my pre-boil volume was on track at 28.9 litres versus expected 28.86, my post-boil volume was over by an identical 40 ml, and mash efficiency was up an astonishing 11 points at 93%.

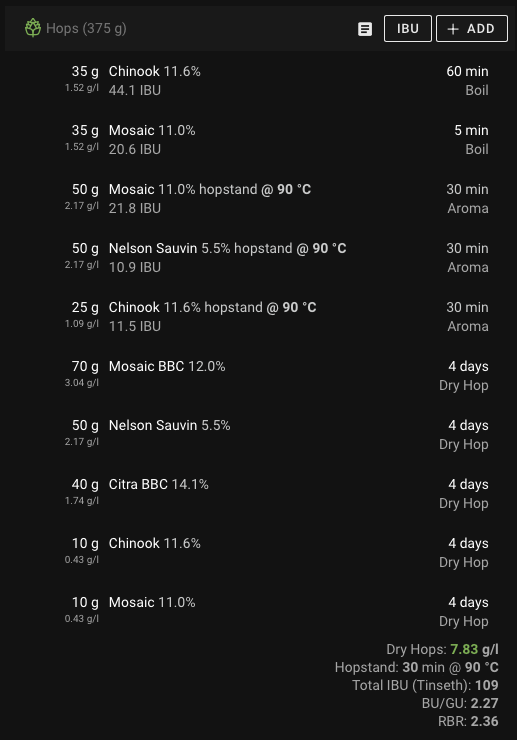

The only fly in the ointment today (there had to be one) was that I made an inventory error when buying ingredients and found myself slightly short of hops, so I had to do a little bit of jiggling.

I don’t think this will ruin the brew but I was hoping to do a like-for-like one the hops and grains so that I can test the effects of substituting my last used Kveik for a sachet of Omega Hornindal and fermenting at 30℃ in order to tease out some of the supposedly fantastic flavours. As it stands any difference between the two brews will now be down to hops as well as yeast, which means I’ll have to do another one a few weeks down the line. Oh the hardship!

Finally, a positive discovery: dropping the Trubinator in upside-down, i.e. with the rubber on top, provides a better seal against the base of the kettle, since the metal edge is 100% flat whereas I can never seem to get the rubber to fully seal, leading to trub leaking out under the sieve instead of getting caught. Maybe this is how you’re supposed to use the device (must admit I never checked the instructions) but it would feel a bit wrong to drop it in during boil and have steel clattering on steel. I say ‘would’ because this only occurred to me during cleaning, so maybe I’ll do some research into the correct method.