Well, that was nice! A really enjoyable brew which I’ll do again without alterations, no problems. Cheers!

Sarka

| Ref | 2021-06 Sarka | Brewer | Pain & Patience |

|---|---|---|---|

| Style | Czech Lager | Type | Beer, all-grain |

| Started | Wed 30th Jun 21 | Status | Archived, |

| Packaged | Mon 26th Jul 21 | Fermenter | Fermzilla |

| Handle | 2021-06 Sarka |

|---|---|

| Brewer | Pain & Patience |

| Style | Czech Lager |

| Type | Beer, all-grain |

| Fermenter | Fermzilla |

| Status | Archived, ABV |

| Started | Wed 30th Jun 21 |

| Packaged | Mon 26th Jul 21 |

We cracked open the 19 litre Cornelius this evening to accompany a Balti, and I must say that Sarka is just great! Not 100% clear yet but very tasty, with only a slight hint of the hoppy bite you’d expect from a Bohemian, and a perfect head of very fine foam. There’s no hint of alcohol at all which is surprising for a 5.1% brew, so I guess we’d best watch out for this one. All-in a very nice beer, just a shame it’s not a bit clearer. So far, so good.

I’ve been itching to get this put away for a spot of conditioning for quite a while now, but with no kegs (or kegerator) space available she’s just had to carry on cold-crashing in the Fermzilla for a bit longer – 2 weeks in total now.

Out with the Old…

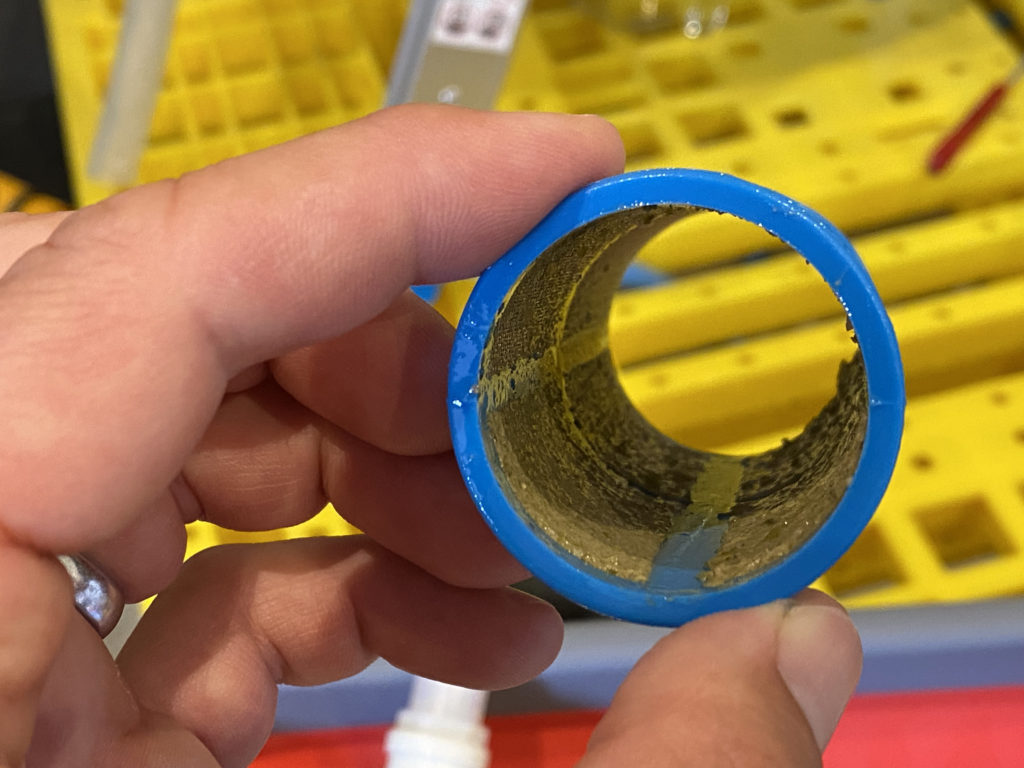

Well, today I eventually drank the last foamy pint of Good Night Vienna, crammed 2 pints into a PET bottle, and chucked out the remaining one or two pints just so that I could free up a 19 litre Cornelius and put away Sarka before going across for a week. Yep, you read that right – I dumped actual beer just to free up a keg, that’s what it’s come to now. To be honest though I’d had enough of the over-carbonated not-quite-lager not-quite-malt style. Going forward I’ll only do this one again in smaller volumes, maybe a 10 litre keg plus a couple of bottles. And I’ll better calibrate my beer lines; the tap that GNV was on is the last one to receive a coiled length of 3/8″ and with just a short length of 5/8″ between the keg and the tap there was way too much pressure for such a short run.

In with the New …

Not much to add here really. It’s late in the day and I couldn’t be bothered to rig up a gas balancer line or transfer filter (should be all clear after a fortnight at 1℃ anyway) so I used a straight liquid-to-liquid line and spunding valve on the recipient keg, transferring at 10 PSI with 9 at the keg and in order to keep the foam down. Filled one 19 litre Cornelius and one 5 litre MJ mini, the Corny went straight back into the kegerator at 10 PSI and the mini’s in the spare fridge. As always, fingers crossed.

It’s time to start cold-crashing Sarka today, so I took the opportunity to add some Polyclar 730 in order to try and prevent chill-haze later on by dropping out all those protein lumps.

The procedure was pretty straight forward even though I’m fermenting at 12 PSI. Simply add 10g of Polyclar to a sanitised 1 litre PET bottle (10 – 15g advised for a 25 litre batch, I’ve just 23 litres in the Fermzilla) and then pressurise to 12 PSI, matching the FV. Connect a line between both vessels’ liquid-out posts, click a tap onto the PET bottle’s gas post, and give it a blip. The reduction in pressure in my “donkey bottle” soon had beer flowing in via the Fermzilla’s floating dip tube, and when I was 80% full I disconnected the tap, stopping the flow between both vessels.

At this point it was time to give the PET bottle a good shake in order to mix the fine Polyclar powder, but no matter how much I agitated the contents I still saw lumps floating about. Leaving it to sit for a few minutes helped, and subsequent shakes momentarily filled the PET bottle with a slightly more cloudy haze which then separated out to settle on the bottom.

Transferring the mixture back to the Fermzilla was as easy as giving the bottle a vigorous shake while applying pressure to the gas-in post, resulting in a flow of liquid back to my FV. It was all very easy, but I’m wondering how effective that Polyclar will be, given that it almost immediately started to settle in the collection jar despite some very obvious mixing as soon as it left the floating dip tube. Oh well, let’s see how she looks after a few days of cold-crashing.

Stepped Fermentation Schedule

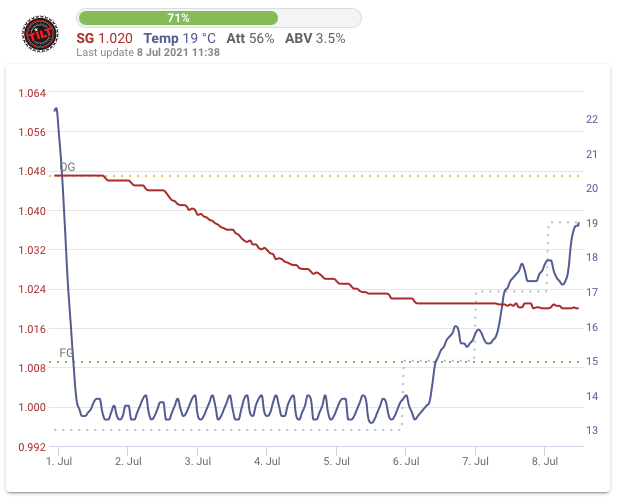

This is the first time I’m following a fermentation schedule which increases in temperature towards the end, presumably to aid the yeast in providing a clean finish. Adjusting the temperature has been very easy; just set a reminder on the relevant days and then make a simple adjustment using the Inkbird app, but it’s the impact on fermentation that’s got me puzzled, because things seem to have slowed down just as I started ramping the temperature up.

My fear is that the change in temperature has somehow flummoxed the yeast and caused it to suspend operations, although most of the Krausen and foam have disappeared instead of stopping dead. There’s still a few tiny bubbles rising up from the Fermzilla’s collection jar, which seems to be half-full of good looking yeast.

Then again …

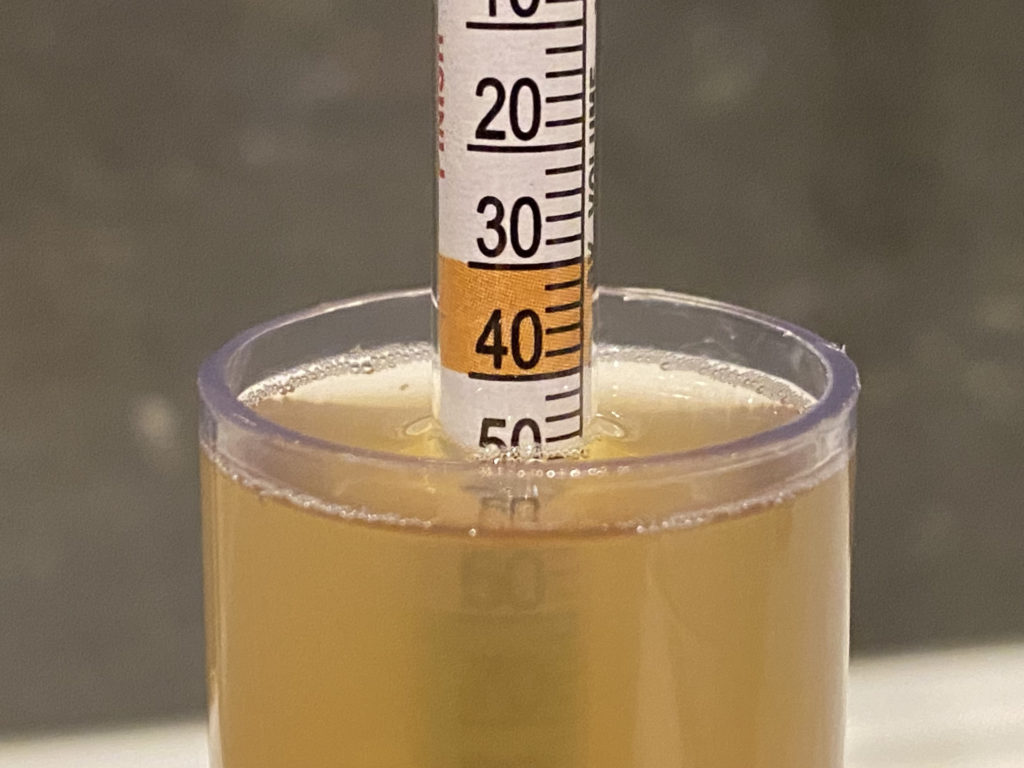

It might just be the readings from my Tilt. At the start of this brew I noticed that the device was reading 11 points lower than my old-fashioned hydrometer, so I did something that I hadn’t done before and specified an 11 point offset within Brewfather, knowing that this may well give me false readings later on because I’d previously noticed that the margin of error seemed greater at the OG end than FG.

For example, Yeti’s actual OG was 1.073 and Tilt reported 1.058 – 15 points low – but the actual FG of 1.016 is just 4 points above Tilt’s 1.012.

If we apply the same 11 point adjustment to Tilt’s current reading for Sarka, 1.020, we’re actually looking at 1.009, which is exactly where Brewfather said we should be right now and explains the levelling out of the fermentation curve perfectly.

Post-Fermentation Finings

Following this recipe has me doing yet another new thing: adding some Polyclar 730 in order to take care of chill haze, which I believe is caused by the interaction of proteins from the wort with enzymes in the hops. Polyclar’s instructions recommend that a dose between 5-25g per litre be added to secondary fermentation, but because I’m not doing a secondary fermentation I’ll be adding it at the end of primary, just before cold-crashing.

The addition process should be interesting too. I don’t need to dump any trub and I’m not dry-hopping, so there’s really no need to de-pressurise down from my 10 PSI fermentation pressure in order to remove the collection jar. Instead I’m going to draw some wort into a purged PET bottle via the floating dip tube, which will already contain the correct amount of finings in an oxygen-free atmosphere. I’ll give this a shake to mix things up before sending it back into the Fermzilla via the dip tube.

Truth be told I’m not 100% happy with using the dip tube for this purpose, but it’s the only way of doing it without risking oxidation because I didn’t fit carbonation caps to the collection jar. There’s still a couple of days to go until I need to start cold-crashing, so I’ll mull it over, but will probably go with the plan as described just now.

The one thing I do know is that, according to the things I’ve read, Polyclar is made up up plastic micro-beads so I’ll have to find a way of making sure the trub at the end of this brew goes to the incinerator and not into the environment. I only discovered this when researching how to use the product, and probably wouldn’t have bought it had I know about its composition earlier.

For almost two days there have been no signs of fermentation other than some minuscule bubbles rising from the yeast and protein which had settled in the Fermzilla’s jar. These came to rest on the surface, making a tiny ring about six inches in diameter and later tracing the outline of the Tilt Pro, evidence of just how little fermentation turbulence there was. Today things have kicked up a gear, and I’m seeing not only the start of a slope in the fermentation graph, but also a building island of foam in the centre of the FV. The spunding valve has also just started to get enough input for me to make a sensible adjustment.

A slow start was to be expected I suppose. Fermentation is always going to be slow at 13℃, which is close to the bottom end of S189’s recommended range of 9-22℃. If anything I’m more concerned about my yeast starter (and pitching temperature) of 23℃ – let’s hope there’s no nasty off-flavours as a result there. I’m fermenting at 10 PSI throughout which will hopefully curtail the esters from here on in, and although I’m not dry-hopping at all I’ll need to reduce pressure down to nothing near the end of my fermentation schedule so that I can chuck in some Polyclar which will hopefully prevent chill haze.

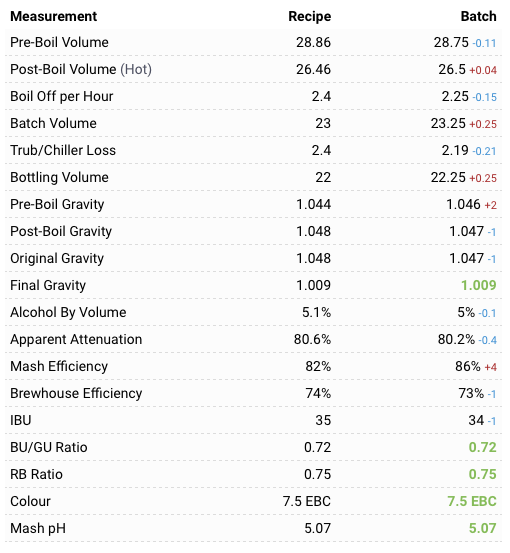

Closing this entry on a final note, I’m really chuffed with how close I’ve gotten to reaching my predicted numbers on this brew, even if I don’t know why.

Could it be that it’s a fairly light beer compared to other recent efforts? I’m not sure what that’s got to do with my lower-than-previous mash / boil / chiller loss, which, if anything, would be slightly higher than reference on account of the 30 minute hop-stand. Then again, a lighter beer is going to be closer to the test run I did using just water, but again I don’t see why losses should increase with gravity. Maybe I just need to get many more brews under my belt and look at numbers again, recalibrating my equipment profile by taking a broader average.

I’ve wanted to try brewing a lager for a long time now, but was always hesitant to try because of the lengthy lagering process involved. Recently I saw a recipe on Brewfather from Gavin Ellicott (YouTube’s Gash Slugg) for Czech Lager using a familiar fermentation method, and it looked pretty easy. Time to have a go.

Brew day went pretty well, and for the first time ever I was close to getting the numbers I had hoped for, though if I’m honest I did cheat a little bit by rounding up my mash and sparge water quantities (21.79 and 9.75 respectively) to the nearest litre, and then tilting the HLT at the end of the sparge because that stage once again passed by very quickly.

Mistakes were Made

The only fly in the ointment was an error I made when transferring the wort to my Fermzilla. My usual process is to switch on the counterflow chiller at the end of boil / hop-stand, monitoring the return temperature instead of the tank temperature. Returning wort from the chiller is much cooler than the tank and typically reaches transfer temperatures of around 20 – 25℃ when the tank is still at 50 or 60℃, depending on the temperature of the mains water used for chilling and the speed of the pump. Once I saw that the return temperature was 23℃, the same as my yeast starter, I turned the upper left-hand valve to send the chilled wort to the Fermzilla via my newly fitted Bouncer filter instead of sending it back into the kettle. Or so I thought. I actually got the setting wrong by 180° which resulted in the return flow from the chiller being shut off entirely, and instead started draining the kettle into my FV.

I should have noticed that the flow was quite high despite the moderate pump setting, that the return temperature was slowly climbing, and that the Fermzilla was warming up, but I was too focussed on the clarity of my wort and making sure that the Bouncer filter didn’t leak because I hadn’t tested it since hastily fitting tribute-clamps. Once I realised my mistake it was too late, and I’d filled the FV with wort at 45℃, a good 20℃ more than I’d wanted. I thought about pumping it back into the kettle somehow and repeating the chilling process, but then I remembered that the recipe I was following also didn’t use a chiller, though that was due to water shortages in Australia at the time. In the end I decided to put the FV into my fridge and chill it to pitching temperature gradually instead of worrying about it too much.

On a Positive Note

The Bouncer filter worked quite well and didn’t leak, which means my PTFE tape did its job. I’ll be using it again next time round, but may switch to the finest filter. Using the medium grade filter didn’t catch as much trub as I was hoping, but that could well have been to the 30 minute hop-stand / whirlpool causing everything to settle in a rough cone rather than leaving it in suspension.

Brew Day Notes

Mashing

07:35 Start mash-in. Using 22 litres mash water and 10 litres sparge water.

07:45 Mash-in complete. Looks pretty thin compared to my previous brews.

08:05 Mash started, first stir. Looks thin in terms of grain density, but its surprisingly cloying and there’s no chance of getting the flow to ‘fan out’ just yet. Mash volume looks like 25 litres, exactly as Brewfather predicted.

08:45 Second stir. Wort seems almost clear before, during stirring it’s full of suspended particles but not as milky as it was at the start. Seems to flow better too, though I’m still not able to fan out without sucking air.

09:04 Third stir. No drama, bit milky afterwards.

09:13 Sucking air, reducing flow inside centre pipe. Not stirring again – I want a nice slow sparge.

09:21 Mashing complete. Turn off centre pipe but leave pump and heaters on, let it settle for a few minutes in order to measure mash volume and gravity: 25.75 litres, 1.063 (1.045 @ 63.5℃)

09:36 I’m raising the malt pipe for a bit of vorlauf to get rid of the last few floaters while my sparge water heats up. No reminder from Brewfather this time, must check the settings.

Sparging

09:43 Ran vorlauf until elements are exposed, wort runs clear and no floaters. Starting sparge now that level’s an inch above grain bed. No tin foil hat this time.

09:49 Sparge complete, letting it drain for a minute or two while I take another gravity reading. I tilted the HLT a little towards the end as I always seem to be short of water and my sparges don’t last as long as I’d like. Volume now looks like 28.75 litres, which isn’t too bad against Brewfather’s predicted 28.86. Pre-boil gravity 1.046 (1.030 @ 61.5℃) against Brewfather’s predicted 1.044. Happy with that.

Boiling

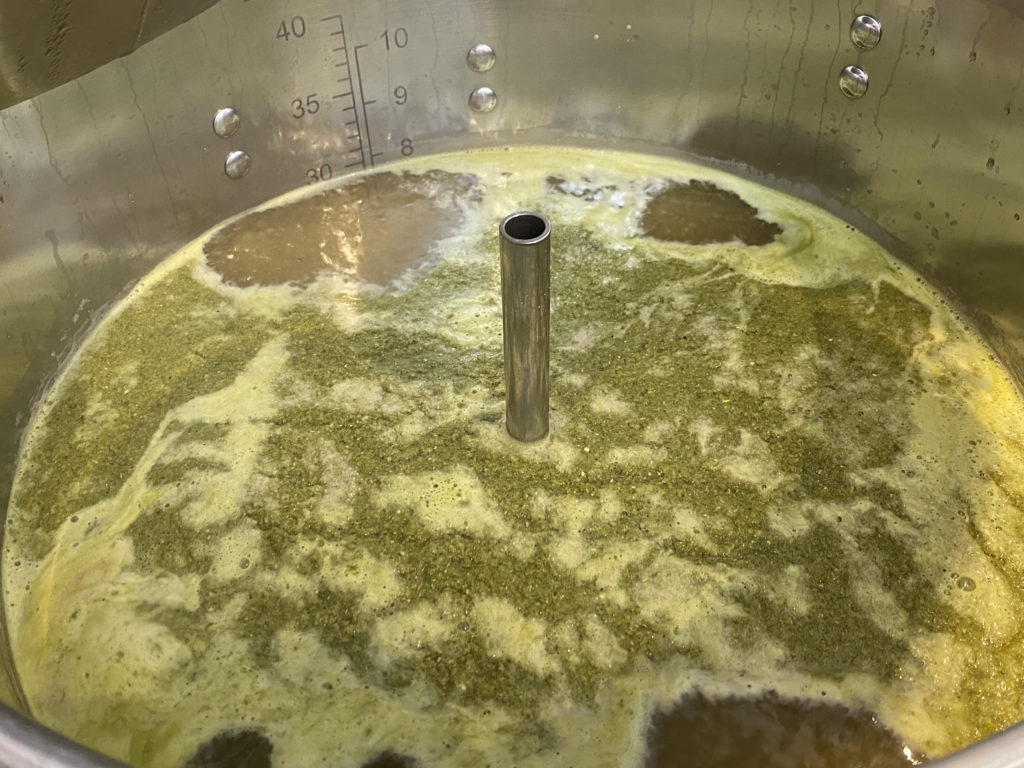

10:25 Boil started at 99℃, 60 minute additions in, steam hat fitted.

11:30 Boil finished, all additions are in. Reducing to 80℃ for hop-stand.

11:35 Starting hop-stand tracker, 30 minute additions in. Going to use this time to try and rig up some tri-clamp fittings for the Bouncer filter.

12:02 There’s 5 minutes left on the hop-stand and levels are 26.5 litres at 79.6℃. (Brewfather predicted 26.45 – nice) Bouncer filter successfully adapted, plumbing into transfer line.

12:09 Hop-stand over, start chill. My yeast starter is at 23.9℃ (supposed to be no higher than 22 – oops!) so that’s where I’d like the chiller return temperature to be before I start transfer.

12:17 Check post-boil gravity while I wait: 1.047 (1.028 @ 65.1℃) which is just one point below Brewfather’s 1.048. Happy with that.

Fermenting

12:23 Return temperature now reads 22.7℃ so let’s start transfer. This time I’m going 100% to out-pipe, not making that mistake again!

12:39 Oh shit, I’ve cocked up again. Incorrect setting of the upper left-hand valve meant that instead of feeding my chilled wort to the fermenter, I was draining the hot kettle directly and running the pump against a blocked chiller. What an enormous tit! The increasing return temperature should have given it away, but I was too engrossed in my lovely clear wort. Oh well, the original recipe also said ‘no chill’ so I’m hopeful she’ll be right, Marv. Into the ferment fridge and dials set for 22℃, presently 43.8.

13:55 Cleanup finished, fridge at 40.8℃.

22:00 Chilled in ferment fridge to 22.1℃ from 40.8℃ in 8 hours. Nearly had another heart attack on opening the fridge – volumetric contraction had put a large dent into the Fermzilla because I neglected to pressurise it beforehand and had the lid on airtight. Idiot. Popping PRV fixed it, let’s hope there’s no damage to the vessel’s ability to function under pressure. The wort was aerated for a minute using bottled oxygen, deployed blue Tilt Pro, then pitched my yeast starter and fitted spunding valve. I’m leaving it fairly low until fermentation gets started, will then dial up to 10 PSI. Fermentation schedule calls for 5 days at 13℃ so I’ve dialled that into the Inkbird and set her off. Fingers crossed!

Oops!

Off to the Fridge

OG 1.047 = Post Boil

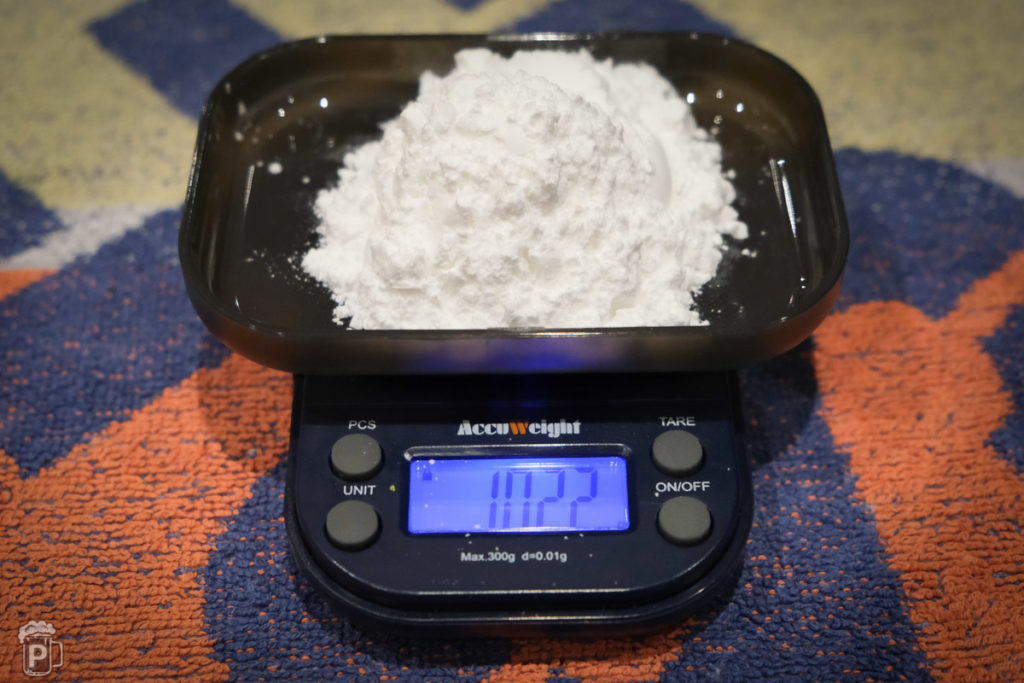

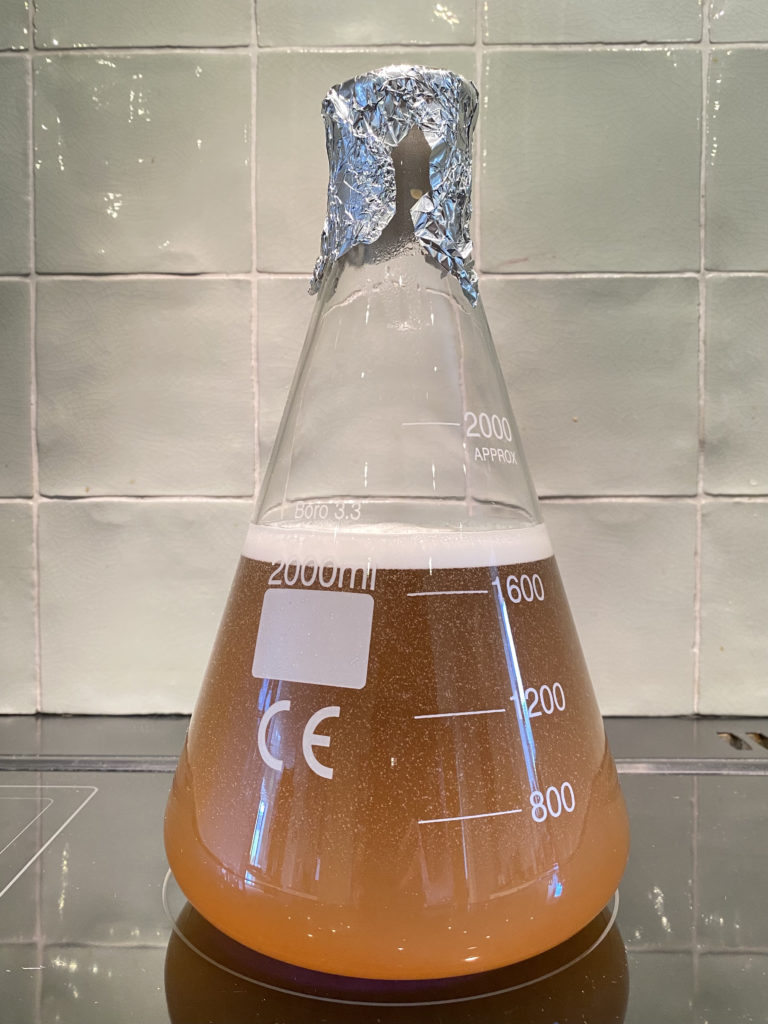

As per Brewfather calculations I’m using 187g of DME for one packet of Saflager S189, but I daren’t fill the specified 1.9 litres of water into my 2 litre Erlenmeyer as that will have me scrubbing the hob again this afternoon. Instead I made do with around 1.7 litres, and even that needed to be removed from the heat and rushed to the sink as soon as it started boiling. Having cleaned the outside of the flask I repeated this step once more and called it quits – the DME looks to have fully dissolved and is probably sterile now, which is all the boiling does anyway.

Chilling the flask in cool water for an hour did little to bring the temperature down, but that’s to be expected as we’re in the middle of a heatwave (22℃ outside – woo!) so I left it in the fridge for a couple of hours before pitching the yeast at 18.3℃ and moving it to the stir plate. That’ll do, pig.

The Next Day

Once again I’m guilty of not letting my starter get to full power before brewing, but it’s got to be better than just sprinkling the dried yeast onto my wort. The starter is now around 18 hours old as I fire up the B40Pro, and has spent the first third of its life on the stir plate and the remaining time on my windowsill around 19℃. The fact that I’m about 200ml of water below the recommended level may have something to do with the slow start, but at least there are bubbles in evidence, and as long as I try to match the pitching temperature to that of the flask it shouldn’t be too much of a problem.