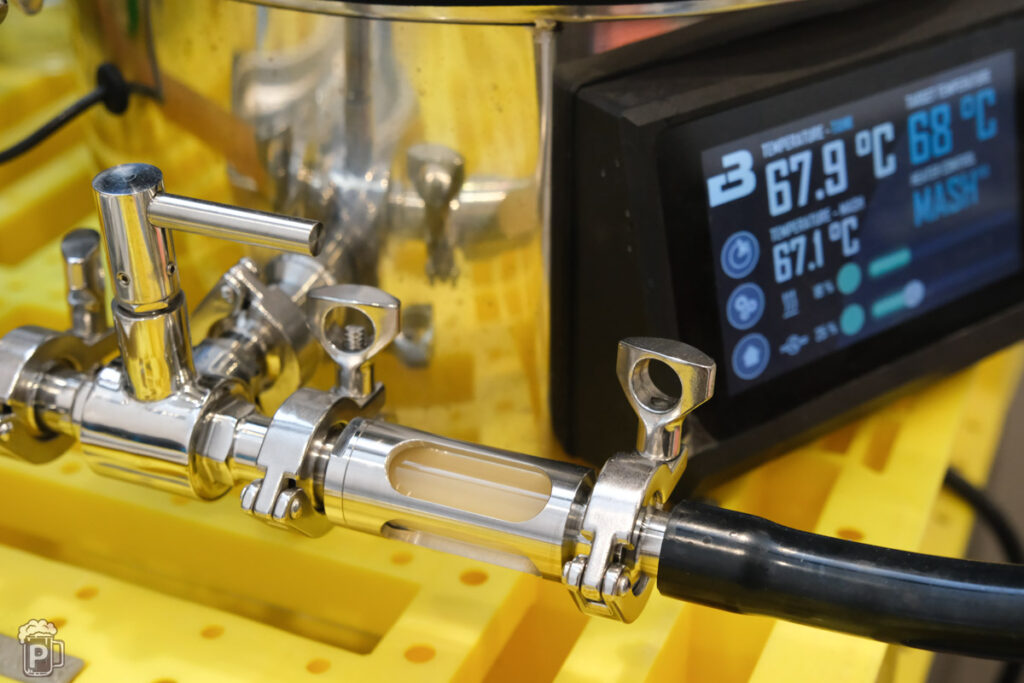

Second brew with the new recirculation manifold, and once again it was an educational experience. Just like Yeti X I wanted to get away with one stir of the mash at the start, but with a kilo of oats in here it was just too gloopy, and I had to add some rice hulls on the fly, then give it a gentle stir now and then. Just as well this style isn’t supposed to be clear.

Mash efficiency was predictably crap then, with me struggling to get a good temperature inside and a reasonable flow through the mash. On a positive note I managed to boil off quite a bit more than expected, and a two litre fermenter top-up put me right back on track with exactly the expected OG and just one litre down on volume.

I’m going to ferment at lower pressure than last time and have pitched just 30g of Hornindal slurry, hoping for some strong apricot flavours.

Brew Day Notes

0605 Start dough-in

0610 Dough-in finished, start mash rest

0635 Second and final stir, fit recirculation manifold, start mashing.

0645 Very gloopy in there, maybe should have added some rice hulls. Mash temperature struggling at just 58℃, tank cruising towards 75℃.

0700 Added two handfuls of rice hulls and gave it a stir. Flowing slightly better, mash temperature just 3℃ off tank.

0715 Threatening to get stuck again, gave it a gentle stir by inserting the mash paddle in between the manifold radials and giving it a twist. No way of knowing if the rice hulls have mixed in properly, but it’s got to be better than nothing.

0810 Time to mash out, but I’m going to give it another 20 minutes to try and make up for lost efficiency.

0845 Cut off centre column to let the levels equalise for measurement. 1.043 @ 69.5℃ = 1.064, looks like 24.75 litres with malt pipe in place. Raising for sparge.

0855 Start sparging. Obviously quite a bit of splashing now, wonder what that will do with regard to HSA? Mash temperature during sparge is 70.4℃.

0900 Sparge finished, letting it drip for a few minutes. Heaters to manual maximum for boil, tank temp 71℃. Looks like 27 litres in there, 1.019 @ 59.6℃ = 1.034. Expected 1.044 – shocking mash efficiency. Will be lucky to get 4% on this one.

0945 Boil tracker started, 60 minute additions in.

1035 Chiller and Trubinator cut in for last 15 minutes, timer paused while temperature climbs back to boil 25 litres before, 24 litres after.

1055 End of boil, chilling for 90℃ hop-stand.

1115 Halfway through hop-stand, let’s take some readings: 23.5 litres (25 including chiller etc) 1.030 @ 77.6℃ = 1.056 against expected 1.048, so we’re back on track for 6% albeit with reduced volume. May do a fermenter top-up, let’s see what we get in the FV at the end of transfer.

1130 End of hop-stand, starting chill.

1155 Chill over, starting transfer. Tank temperature 24.0℃, return 19.0℃.

1215 Transfer finished, 19 litres in FV. Topping up to 22 litres, OG 1.048 against predicted 1.048. That’ll do, pig. Pitched 30g Hornindal, deployed blue Tilt Pro, into the fermentation chamber and dialled to 34℃.

1325 Clean-up finished.