Can’t believe this is my tenth go at an imperial stout! Each version has been slightly better than the last, and I’m getting closer and closer to hitting those magic efficiency numbers. This time around I’m also using two new pieces of equipment; an auxiliary temperature probe for the mash, and a brand new recirculation manifold from Brewtools.

How did it go? Pretty well. The probe gave me a better insight into the core mash temperature and showed me that by relying on PID tank / pump temperature I’m actually a few degrees off when it comes to the mash, which will have impacted my efficiency as well as the ratio of beta-amylase to alpha-amylase enzyme extraction, and with it the character of the finished product.

The recirculation manifold was an even bigger revelation, because while wondering how that thing is going to fit into the filled malt pipe on a big beer I was forced to look at my mashing technique thus far, specifically with regard to hot side aeration (HSA) and filtering. Turns out that splashing hot wort about introduces oxygen, and while I knew that I hadn’t realised that it can lead to undesirable flavours later on. Maybe I don’t keep my beer long enough? Who knows. Anyway, another aspect / lesson learnt is that the speed of the flow through the mash isn’t as important as the enzyme extraction (hello, temperature) and that’s where the recirculation manifold comes in.

Basically, this sits just below the top of the mash, and circulates wort into the upper layer via small holes in the arms. The upturned ends are designed to poke out of the mash, so that if some grist or grain interferes with the smaller holes it can be effortlessly expelled. At first I thought I wouldn’t have enough room to mount this on top of the centre column, but it fitted just fine with this recipe, aimed at 15 litres fermenter volume.

Another concern I had is that I wouldn’t be able to stir the mash with all those arms in the way, but after watching a video of somebody else using it I was convinced to try a new (for me) technique: stir liberally during dough-in, once more after initial mash rest, fit the manifold, don’t stir again. Initial fears that the mash would become stuck without stirring soon faded away as the manifold allowed me to get a fairly decent flow through the grain without going over. As a bonus the resulting wort was also perfectly filtered since I had no reason to disturb the grain. Very nice!

So was this the silver bullet I’d been waiting for? Not quite. My mash efficiency was still just 60% and my Brewhouse efficiency just 59%, but at least I’ve had a go at something different and feel progress was made, if only in terms of laying new foundations.

Brew Day Notes

0645 Start dough-in, stirring all the way.

0700 Dough-in finished, everything nicely mixed. The new mash temperature probe has been deployed, and it’s only 61℃ in there. Hmm. Increasing thermostat from 66 to 70℃ to see if we can get that core up to speed.

0715 A quick stir, and we’re anywhere between 63 and 68 depending on where you rest the probe.

0745 That’s enough mash rest. Quick stir and fit the new manifold, which was actually less of a faff than expected. I’m orientating it with the clamp at the top and there’s enough room for it to be just submerged, in fact I’m having to lower it very slightly on the centre pipe. The idea – a new one on me – is to avoid splashing wherever possible (HSA) so I’m gently recirculating just inside the top of the mash.

0755 The new temperature probe is reporting 60.5℃ in the mash despite the controls (mash mode) being set to 70℃. I’m going to manually control this while watching (how?) for charring on the elements because mash mode at 50% isn’t cutting it.

0800 I just realised that the heaters are still off from when I gave it a stir at the end of mash rest, so increasing the power slider obviously isn’t achieving much. Tit. Mash core temp now 59℃ but rising again.

0815 We’re back up to 66℃ at mash core, will extend the mash time by 20 minutes at the end.

0905 Looking back over the last brew, I was at 1.061 after 90 minutes of mashing. Now that I’ve been running about an hour (albeit not at target temperature) I’m seeing 1.048 @ 60℃ = 1.064, which is great! The sample looks clearer than I’m used to thanks to no stirring so far, and flow has been no problem despite no stirring so far, all of which is due to the new recirculation manifold. Increased yield isn’t statistically significant in itself because the recipe is different from last time, but being able to maintain the mash core temperature more accurately is likely to have contributed.

0915 Fore reference, I’m circulating with pumps at 35% and split roughly 5 degrees from a 50/50 split between recirculate and centre pipe, biased towards recirculate. Target temperature is 68℃ and the pump is at 67.8℃ with heaters (auto – mash mode) holding the uncovered mash tun at 22%. Mash core is at 66.1℃.

0920 Setting target temp to 78℃ in order to get the mash core to 75℃ for mash-out.

0925 Auto-mash mode isn’t cutting it, not limited at 50% anyway, with the tank now at 71.1℃ and the core at 66.9℃. Going manual, heaters to 70% for now. Volume looks like 26.75 litres.

0930 This is taking too long; 75 / 69℃. Heater to 80%.

0940 Core now at 73℃, tank at 81℃. That’s close enough, given the amount of variation just by moving the probe about. Target back to 78℃, heater to mash-auto, and start 10 minute mash-out timer.

0950 Mash-out done, heaters set to off and prepare to raise the malt pipe. I’m not looking forward to this; without a winch I can only raise the mash as slowly as my back allows, which will lead to considerable dripping as it clears, partly undoing the manifold’s work of avoiding HSA. A winch would allow me to raise it more gradually and have the bottom of the pipe rest just below the surface of the kettle until it’s mostly drained. One for the drawing board I think.

1000 SG 1.050 @ 63℃ = 1.068. 30.75 litres with malt pipe in. Lifting now.

1005 Lifted clear over maybe 3.5 minutes, very minimal dripping going on. This is better than expected. Volume looks like just 18.5 litres now (expected 19.48) so we’ll leave it a few more minutes. Heaters to auto / 90℃ hold while I clean the malt pipe.

1035 Malt pipe and manifold cleaned, heaters to maximum.

1045 Boil tracker on, 60 minute additions in. Pre-boil gravity carried over as 1.068 (expected 1.076) volume 18.5 (expected 19.45). Mash efficiency shown as 59.74% which isn’t great, could we have increased that by longer dripping, and greater chance of HSA? Probably. GAR may also need tweaking again at some point.

1125 Adding 15 minute additions, dropping in chiller coil and nutrients. No trubinator this time – I think the practice of not stirring my mash will have saved a lot of grist from making it into the kettle, and I’m not exactly adding a ton of hops to this brew. Volume before 16.5, after 15.0 litres. Pausing timer for a moment while tank temperature returns to boil.

1135 Resuming boil tracker

1145 5 minute additions in

1150 End of boil, start chill. Pump at 25% and return temperature dropping nicely.

1155 Increased the pump, and it seized. Arse.

1200 May have been semi-false alarm, saw it sucking air via the dip tube but not loud enough to make noise. Managed to clear it by stop-starting, now whirlpooling at 35%. SG 1.072 @ 47.4℃ = 1.082 against predicted 1.087. Won’t be topping up the fermenter then, lucky to get 9.2% ABV.

1210 Starting transfer. 25% pump is a good setting, return temperature 20.5℃, tank at 28.5℃.

1225 Transfer finished, deployed starter and red Tilt Pro. Conservative guess at fermenter volume maybe 14.5 litres? Expected 14.0, so that at least isn’t too bad. Call it 15 with starter. Quite a bit of trub and dead grist in the kettle though.

1330 Clean-up finished

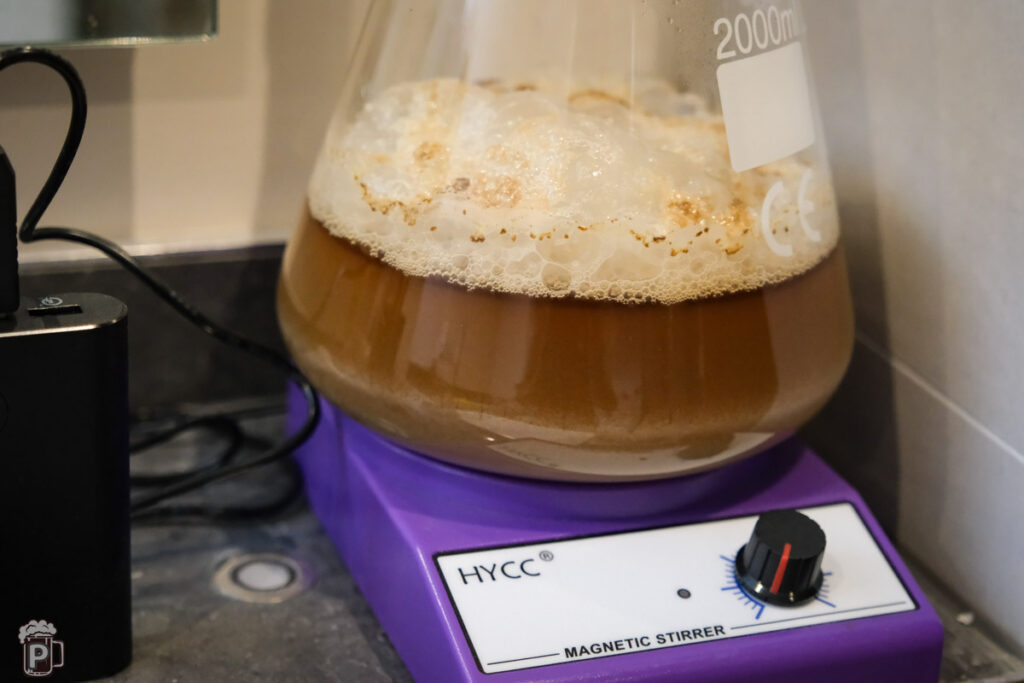

1800 First signs of regular bubbling from the blow-off tube

#wisdom: Heaters off = dip tube down. Don’t be sucking unplanned air, risking pump seizure on big brews.