After my recent Stout and then the Vienna Lager I’m ready for something lighter, so I put together this recipe from scratch in Brewfather, loosely aiming for an American Pale.

Brew Day Notes

06:45 – Begin mash-in. Heaters have been on since 06:00 from 17℃, water filled to just below 24 litre mark last night, everything wet except chiller coil. Maybe next time I’ll work up the courage to use the timer function so that I reach strike temperature (68℃ today) while I sleep, but for now I’m happy to get mash-in complete and start the 20 minute mash-rest by 06:55.

Mashing

07:17 – Start mashing. Observed level just below 30 litre mark.

07:44 – First stir done. Mash looks a little looser than usual, ramping up the pumps to 60%, mix lever roughly at 4 o’clock, seeing if I can maintain a fan above grain bed without the dip-tube sucking air.

07:55 – Circulating exclusively outside the malt-pipe for a few moments to get a measure of the levels – looks like 28 litres. That’s slightly pessimistic as the level inside the malt-pipe is maybe half an inch higher, but I don’t want to waste valuable mashing time waiting for those levels to equalise. Second stir, back on with the wort fan. 25 minutes to run.

08:17 – Third and final stir done, fan still good but slightest hint of whirlpool above the dip tube. Wort seemed almost clear before stir, and although a bit of haze was disturbed from the bottom of the malt-pipe it settled out very quickly and became clear again. Looks like this will be another lightning sparge.

08:20 – Target temperature increased to 75℃ in preparation for mash-out. I’ve built 15 minutes into the recipe in order to achieve this, let’s see how close I am.

18:36 – Bang-on 75℃ after 15 minutes, what a guess!! Mashing out for 10 minutes then gravity reading, vorlauf, sparge. Wort looks lovely and clear.

08:56 – Post-mash levels 24 litres indicated. Post-mash gravity = 1.063 (1.052 @ 49.8)

Sparging

08:58 – Start sparge, HLT temp 75℃. Very difficult to maintain any kind of evenness despite tin foil hat and constant juggling of HLT valve / pump.

??:?? – Bollocks, forgot to time the sparge again!! Didn’t feel like very long anyway, and I’m still not sure about the distribution of water on top of or inside the grain bed. Kind of feels like no matter where I try to channel it using the punctured tin foil and gentle encouragement of pooling, it just runs through the mash which then dribbles for a while but ceases again quite quickly. Pre-boil gravity 1.049 (1.031 @ 64.9) against predicted 1.046 – 3 points up!

Boiling

09:15 – Malt-pipe out, heaters to 100%, manual control.

09:31 – Malt pipe cleaned, temperature in kettle at 94.1℃. With gravity samples returned (hey, it’s pre-boil and every drop counts) and expansion I’m looking at approximately 30.5 litres, which is near enough my planned pre-boil volume of 30.94.

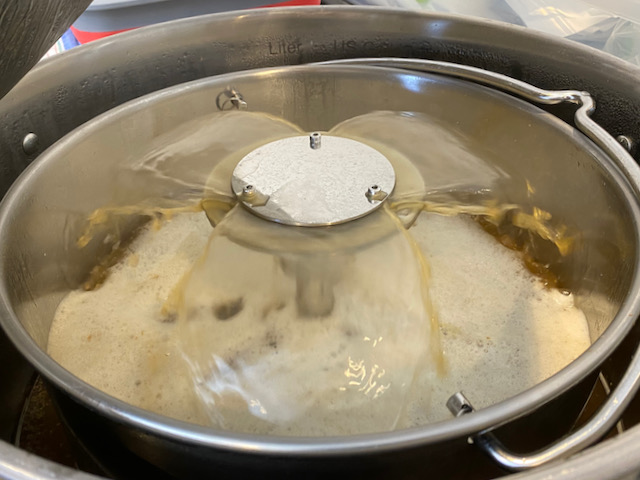

09:35 – Foam on top. I think in the US they call this the hot break, whereas over here the hot break is the protein that floats around in the wort like egg soup. Maybe they’re one and the same, but at different stages, who knows. I try to give it a stir but that only seems to increase the foam … and lower the apparent wort level by half a litre. Weird. Steam hat and condenser fitted

09:41 – Boil tracker started, we’re rollin’! Turn on condenser feed, 60 minute additions in.

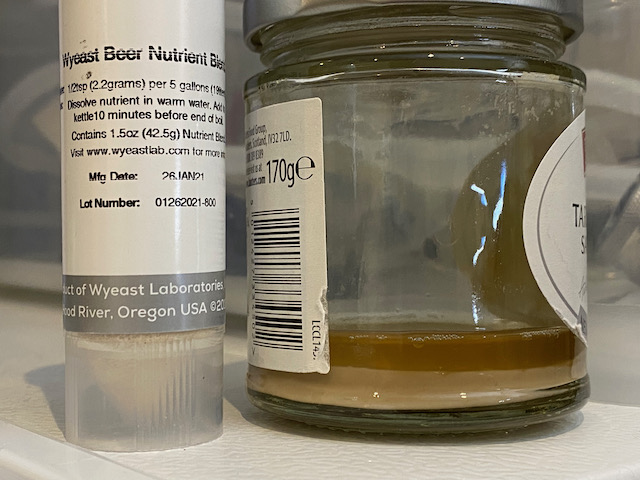

10:21 – 20 minute additions in, all looking good. Fermzilla floating dip tube fitted to lid, start sanitising the aeration kit. Yeast and nutrient already collected from fridge, acclimatising to room temperature nicely.

10:28 – 15 minute additions in (Protafloc and yeast nutrient) starting circulation through chiller to sanitise, heaters to max.

10:31 – 10 minute additions in, starting to boil again after a slight thermal hit from the chiller. Need to keep an eye on this and not let boil get too intense otherwise the recently added hops will crust at high tide and not contribute. Forgot to measure levels before cutting chiller in, but now it’s in I’m looking at around 27 litres, which doesn’t sound as much of a loss as with previous brews. From memory I think the chiller is around 2 litres, so I’m putting this down as 29 litres post-boil.

10:40 – Heaters off, measure level before turning on chiller feed: 26 litres hot.

10:50 – Tank temperature down to 61℃, return from chiller 29℃. Getting ready to plumb in the Fermzilla.

Transfer

11:13 – Transfer to FV is complete, but despite watching my chiller return temperature I’ve ended up with 46℃ in the Fermzilla. Maybe it’s because I was using the pump at steady 5% so as not to disturb my pyramid of kettle trub, and regulating the flow to my FV using the upper left tap halfway between returning to kettle and pumping to Fermzilla. Instead of pumping to kettle it must have been pushing wort from the kettle and the chiller into my FV. Oh well. Wort is aerated and the lid with dip tube is resting on top, ready for pitching as soon as it gets cool enough. I can’t see this taking much more than an hour. Let’s see how the values stack up, maybe I’ll do a chiller top-up with some iced water to hurry things along.

11:16 – FV volume is very approximately 23.5 litres, OG 1.056 (1.051 @ 36.3) which means I’m 2 points ahead of Brewfather’s estimate of 1.054 but 1.5 litres behind my target fermenter volume. Great news all round, except for the cock-up with the temperature. Hopefully standing around for the next X hours won’t affect the brew too much – next time I’ll have a couple of litres of slush on standby.

12:40 – Cleanup finished, Fermzilla in the Fridge minus yeast, heading for 25℃ but presently at 35.6.

21:11 – Temperature down to 21.4℃, pitched a teaspoon of Opshaug Kveik originally top-cropped from Good Night Vienna and then revived on the stir plate before being stored in the fridge for a while. Spunding valve has been fitted and will be dialled to 5 PSI as soon as the needle moves.