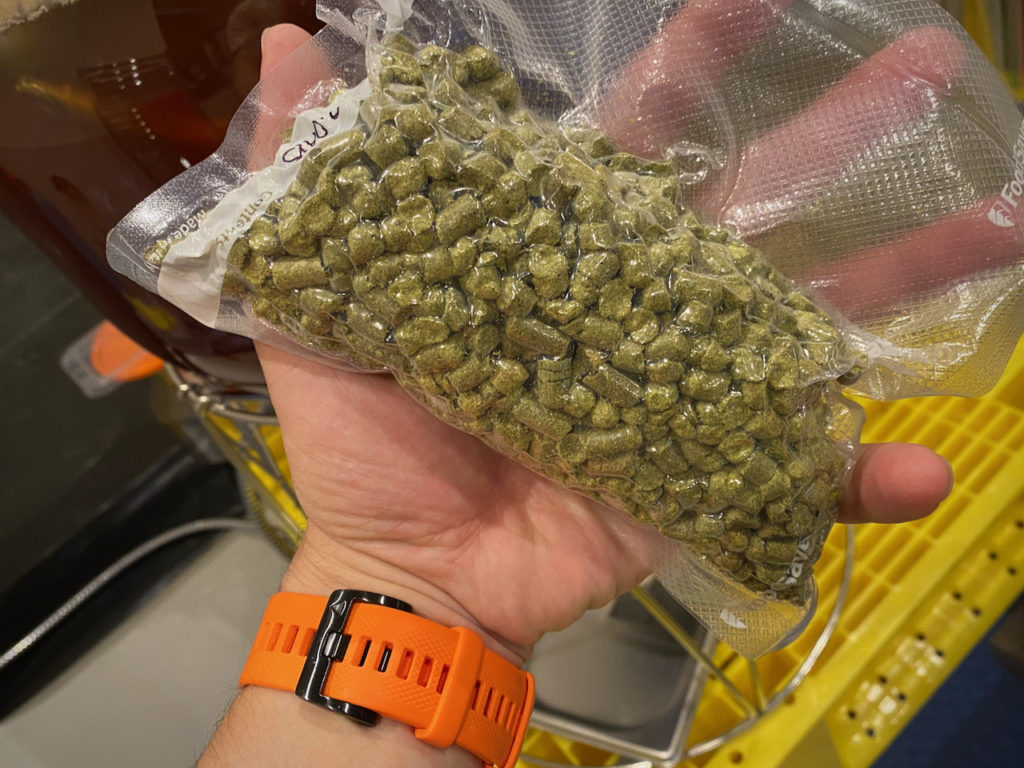

There’s some very slight signs of fermentation going on and still a bit of Krausen remaining, but I’m going to stick to schedule and remove the trub, then chuck in some hops. Added today were:

- 93g Falconer’s Flight 11%

- 55g Amarillo 9.2%

- 55g Mosaic 12.25%

The procedure was broadly the same as when I dry-hopped Golden Wave just over two weeks ago; reduce FV pressure to 5 PSI, shut butterfly valve, de-pressurise collection jar completely via the fitted carbonation cap and drain as much liquid as possible before unscrewing.

I did a couple of things differently this time around, starting with the gradual reduction of FV pressure from 10 to 5 PSI over the space of 24 hours. I wanted to see if this would help to clear up some of the remaining Krausen (it did, but that may have just as likely been the additional 24 hours too) and because it felt like a respectful thing to do to my expensive WLP001 yeast. Speaking of which, another thing I did differently this time was to save some of that yeast in a sanitised plastic beaker for a reuse experiment over the coming days.

Introducing … [thing]

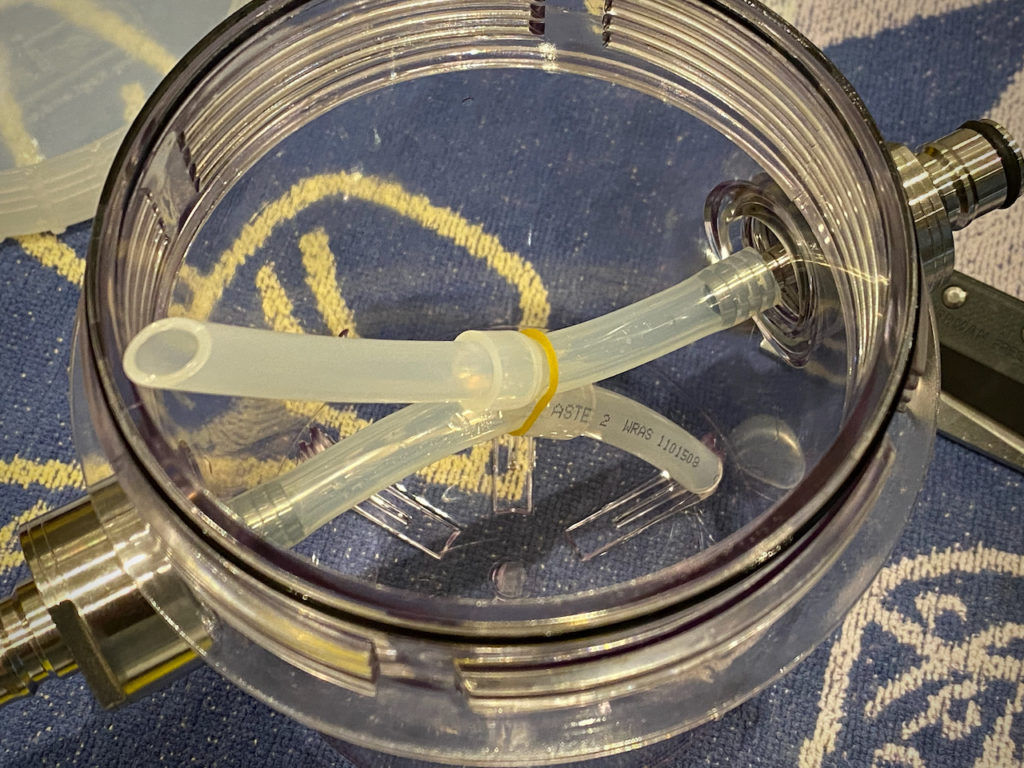

One last change today was the implementation of a device I’d been thinking about for some time, but I’m not sure what to call it yet, or if even it needs / deserves a name. Basically, flushing the hop-filled collection jar with CO2 before releasing the pellets into the fermenter is a process I’m not 100% happy with, specifically the efficiency balance between retaining as much hop aroma as possible while driving out the oxygen.

Pumping heavier-than-air CO2 into one side of the jar is all very well, but purging it by releasing a valve on the opposite side will probably just let out the same CO2 plus some hop aroma, since the lighter-than-air oxygen is out of range at the top, hiding near the butterfly valve. Today I’m trying to get around that limitation by fitting two tubes to the carbonation caps inside the collection jar, the inlet tube going to the base of my pile of hops, and the outlet tube going as high as it can without interfering with the jar’s seal or the butterfly valve.

My thinking behind this is that I’ll slowly push some CO2 into the base of the jar via that pipe on the left, while the pipe on the right lets out oxygen from the top. I’ve no way of telling if this works since I lack both a control candidate and a dissolved oxygen (DO) meter, but it’s got to be worth a shot. As before, any oxygen that made it into the FV when the butterfly valve was opened is purged via a couple of pops of the pressure relief valve, just in case. Is it worth going to all this trouble seeing as I still have the PRV method? Not sure, and no way to measure. Provided everything is sanitised there shouldn’t be any risks, so why not?

Finally, releasing the hops into the FV by opening the butterfly valve was easy as always, but also the gentlest dry-hopping to date, with hardly any commotion inside. For a few minutes I was concerned that this might not be a good thing, since I want the hop pellets to be utilised as much as possible, but they broke up soon enough and a significant portion made their way to the surface.

On a related note, I read today about a method of adding hop tea created using a cafetière (French Press, as the Septics say) instead of dry-hopping, and that’s something worth experimenting with in future I reckon. Utilisation can’t be worse than dry-hopping (even if you steep below 77 ℃ to prevent isomerisation / bittering) and it should minimise DO absorption too. To be continued …