Another brew day, another first: Imperial Stout. This high ABV brew took a bit of jiggling to get it to fit my equipment profile and in hindsight I’m not sure that my take on the original Brewfather recipe was totally viable to begin with. Once I’d dialled in EBC values for locally available fermentables and applied my hardware profile I was right up to the limit of the B40s capacity, and that’s with no sparge water.

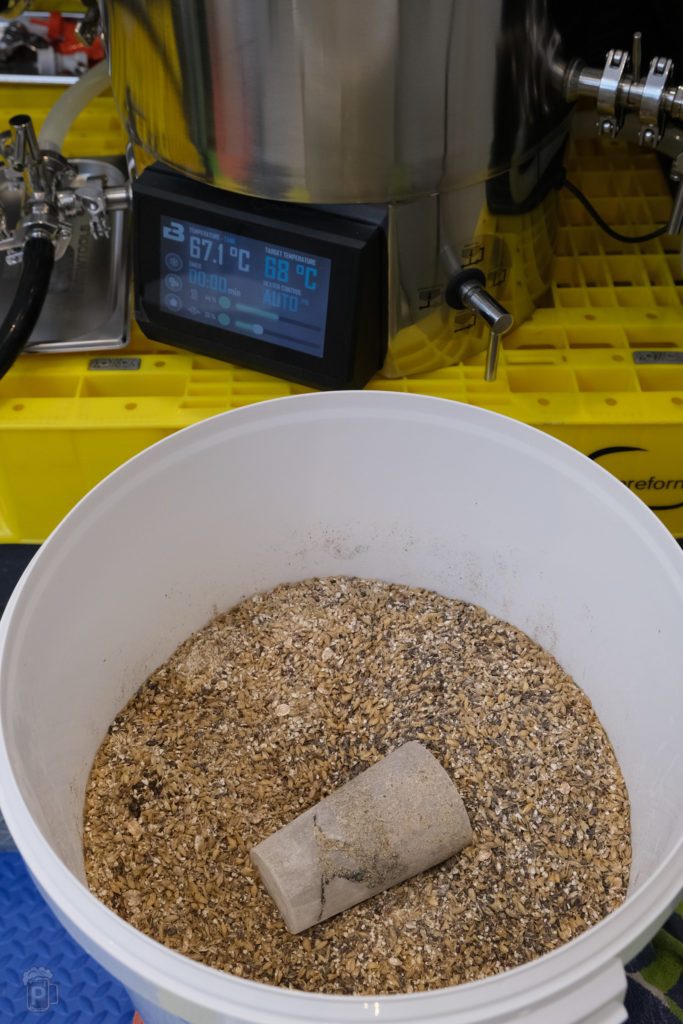

Still, it’s got to be worth a punt, and if anything the lack of sparging should be one less thing to worry about, right? Hmm. I don’t know why, but this brew day felt like hard work. For a start, the grain bill was 7.2kg and I had trouble getting it all into the malt pipe for the initial 20 minute mash rest. Consequently dough-in took a little bit longer, and once I was ready to start mashing there was no question of trying to achieve the usual fan of water from the sparge hat – the grain bed was just too high and there was no room to play with. Instead I set the pump for about 50% power and fed as much wort through the centre column as I could, backing it off when the level approached the holes where the handle connects to the malt pipe. I stirred every 10 – 15 minutes and that allowed a bit more worth through the grain bed, but as things slowed up again very quickly it was a case of constantly managing the balance between inside and outside the malt pipe.

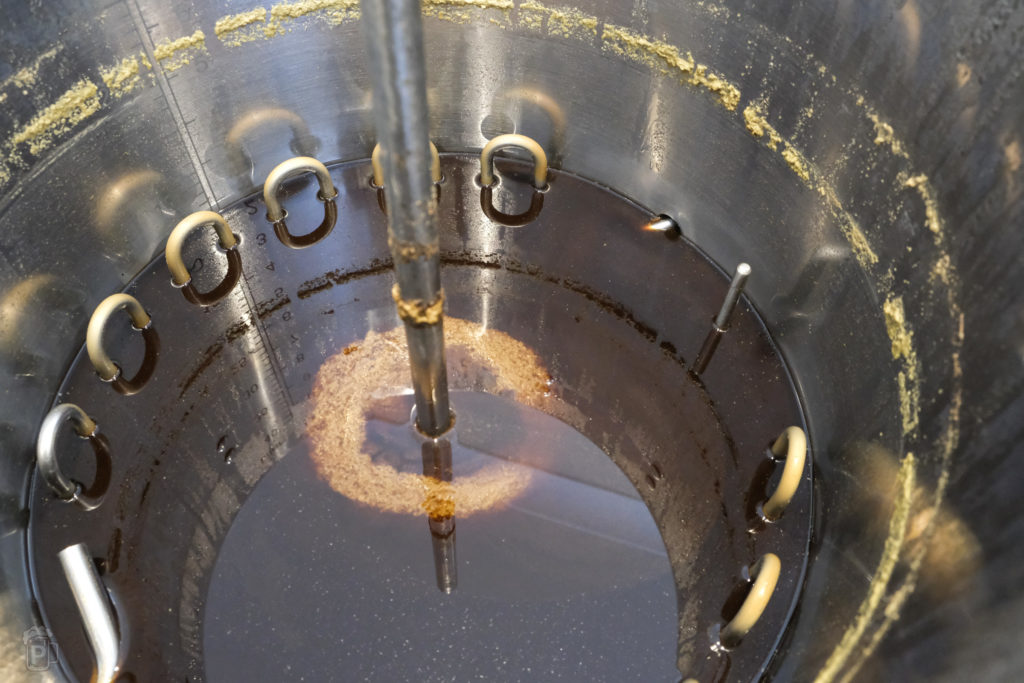

The wort flowing out of the sparge hat was wonderfully dark and emitted a deep, rich aroma which permeated the brewery comprehensively, sticking around longer than that of previous brews. There was also quite a bit of detritus in the wort and I later regretted not fitting the Bouncer filter when transferring to FV – must get that sorted for the next run.

Once again I lost a lot of liquid during mashing and then yet more than planned during boil. Gravity was down too, so I need to sit down at some point and figure out if and where I went wrong with my hardware profile, or where I’m going wrong in my procedures. I’m writing this just over 24 hours from clean-up because I don’t want to leave it as long as last time, but still haven’t sat down and compared all of my measured values to those that Brewfather predicted, save for the all-important ABV, where I’ll be lucky to pull 8% against the predicted 9.6%. Not gonna be very imperial, this Stout!

Brew Day Notes

- Took yeast off stir-plate 06:00, temperature has crept up to 23℃. Doesn’t look like it’s reached Krausen yet, but some signs of separation as the upper layers under the foam begin to darken. Very small bubbles continue to rise to the surface.

- Filling B40 with recommended 29.5 litres water as per plastic measuring jug shows maybe 28.5 litres on the internal scale with the malt pipe fitted. Topping up to 29.5 while heating takes 1.5 litres – really must get those measuring jugs calibrated sometime or find another way of checking the B40’s scale.

- Heaters on full 06:06, tank temperature 11.5℃.

- Strike temperature reached 06:52, starting dough-in

- Dough-in finished 07:15 and damn, this mash is thick! Didn’t think it would all fit in. We’re up to 36.5 litres on the internal scale now (wasn’t the B40’s limit 35 litres? Maybe I should have measured volume hot and not topped up 1.5 litres after all) and it’ll be tricky trying to keep liquor moving through the mash without overflowing. Can see now why there’s no sparge step – unimaginable! Letting the mash rest for 20 minutes now.

- 07:45 and I’m 15 minutes into the mash. Pump set to 50%, I’m balancing the flow outside / through the malt pipe using the right-hand valve alone. There’s no question of fanning the water out, all I can do is vary the trickle until the malt-pipe level approaches my upper limit: the holes in the sides where the handle connects. First stir reveals no dough balls but raises a little foam. The mash itself isn’t that thick and the paddle cuts through like normal, but it’s deep. Temperature 4 inches down varies between 64 and 66, I have the dials set to 67℃. The wort is very dark and smells amazing.

- Mashing done at 08:35 but I’m keeping things running while I take a sample. With no sparge step I may as well do a bit of vorlauf with the malt pipe raised so that I can trap some of the debris that was released during a recent stir approximately 3 minutes from the end.

- Sample reads 1.049 @ 57℃ = 1.063. Brewfather predicted 1.078 – oops! Definitely doing that vorlauf, maybe increase the boil time to make up the difference in post-boil, even if it means lower volume.

- Finishing approximately 10 minutes of vorlauf by turning the heaters off, lowing the dip tube, and pushing as much through the malt pipe as possible in order to clear the wort of any remaining grains.

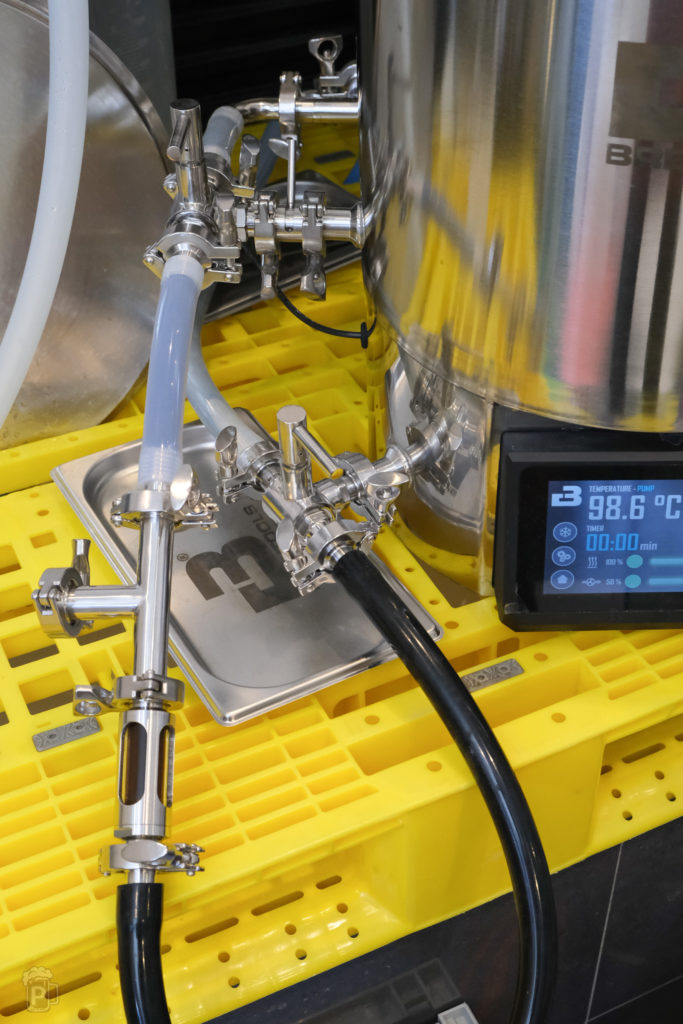

- After a minute or three it’s back on with the heaters, stop flow to malt pipe, start heading for boil while the wort drains. Setting a timer for 30 minutes but leaving heaters on auto mash mode (50% limit, 90℃ target) while the malt pipe is in the way and I can’t be sure there’s no floating grains to scorch the elements.

- Using this time to rack 9.5 litres of Thirst Scratch to the small SS bucket for my HFR experiment.

- 20 minutes left on that timer and there’s practically nothing coming out of the malt pipe now, seems well drained. I think about giving it a gentle squeeze from the top but don’t want to force bits of crud through the filter and into my wort. Raising the pipe now.

- Pre-boil volume 22.5 litres (BF=24.69) gravity 1.044 @ 64℃ = 1.062 (BF=1.078). Looks like I didn’t gain anything at all by draining the malt pipe or vorlauf, interesting. Volume is down two litres as well, so I can’t make up too much gravity by boiling longer, and Brewfather predicts 7.7% ABV. Balls.

- 09:42 – boil started, 60 minute additions in.

- 10:00 – needn’t have worried about the yeast, which appears to be in high krausen after a couple of hours off the stir-plate

- 10:13 – 30 minute additions are in, looking good.

- Keeping the heater at 70% occasionally caused the brew to go off the boil, raising it again for too long causes high-tide marks of hops which stay up and probably don’t get utilised as well as they should. Ho-hum. I’m not removing the steam hat to fix that – last time I did so the plasterboard ceiling gave indications that it wasn’t happy with the idea.

- 10:32 – 15 minute additions in, chiller cut into circuit.

- 10:40 – 5 minute additions in, fitting aeration kit for sterilisation.

- 10:48 – bit of a tense moment when the pump jammed as I started circulating through the aeration kit, but pulsing it at 75% power eventually freed it. Phew!

- 11:00 – about to start transferring to FV, looks like about 18.5 litres in the kettle.

- 12:00 – released the yeast monster, deployed Tilt. OG 1.073 @ 19.6℃ (BF = 1.087)