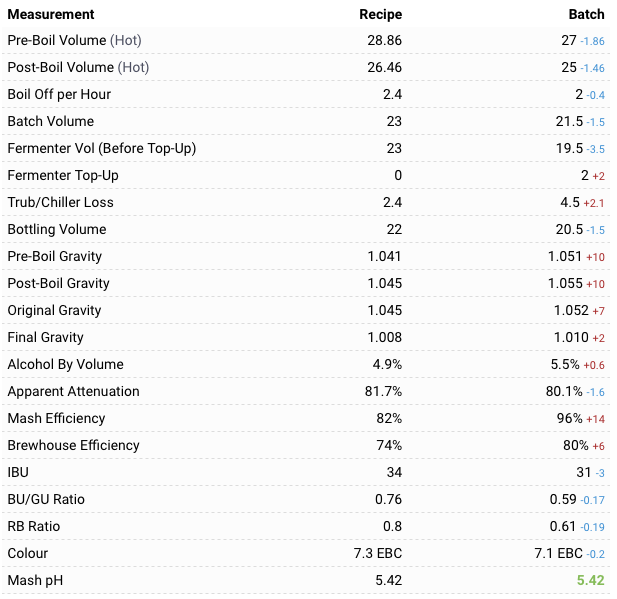

Fairly good brew day today with no mishaps to report. I’m still not hitting ideal numbers (specifically pre-boil volume, with almost two litres unaccounted for during mashing) but on the flip-side I’m extracting more than predicted from my grain so those volume losses are partially recovered through fermenter top-up.

Speaking of which, I don’t see the point of adding water to the fermenter in order to bring the volumes back up, unless it’s mineral water from a sealed bottle, which I didn’t have. Instead I added filtered, boiled water from the Zip Tap to the last 10 minutes of boil, figuring that it’ll become sterilised as it boils and that any losses thereafter would be minimal anyway.

This approach worked well for me today, but I hadn’t figured on there being so much trub left behind, both inside and outside the Trubinator, a device I’ve yet to be truly convinced by. Consequently I left behind more wort than usual, adding another 2 litres to my expected trub / chiller loss. Could I have extracted another 3 litres by fitting an inline filter? The last time I tried that my pump gummed up because it was allowed to rest while the filter was fitted, and I ended up pulling in way more trub than I would have liked, so I wasn’t about to go there again. Oh well. Both mash and brewhouse efficiency numbers are way up there so I’m not complaining.

On a parting thought I can’t help but wonder if some of that trub is due to the Polyclar which went in as part of the 10 minute additions. I didn’t use it in my last bash at this recipe and couldn’t tell the difference, so I’m really just throwing it in today because it’s in Gash Slugg’s original recipe. There was quite a bit of hot break when those final additions went into the boil, and it took the full 10 minutes to dissipate.

Brew Day Notes

0825 Started dough-in

0839 Dough-in finished, started mash rest

0901 First stir, start mashing.

1021 Mashing complete. SG 1.063 (1.047 @ 60.2℃) volume about 25.1 against predicted mash volume of 25 litres. Guess that’ll be due to expansion towards the end of the mash, certainly hints at minimal losses so far.

1032 Malt pipe raised, starting vorlauf.

1035 Starting sparge.

1042 Sparge finished, letting her drip while the heaters ramp up to 90℃. SG 1.051 (1.035 @ 59.8℃) against predicted 1.041 – wow! Boil volume should be 28.86 but we only have 27. I’ll need to add just under two litres to hit my numbers, which I’ll do towards the end of the boil.

1122 Boil tracker on, 60 minute additions in. Hot break started to build in the high 90s and went as soon as rolling boil stared and the hops went in.

1207 15 minute additions in.

1213 Stopped heaters in order to take some readings ahead of adding 10 minute additions, which may include some top-up water. SG 1.055 (1.028 @ 78.8℃) volume 25 litres. Post boil kettle volume should be 26.46 so I’m going to add 2 litres now along with the 10 minute additions and bring her back to boil. Not worried about change in gravity as I’m still 10 points ahead.

1229 Chiller and Trubinator cut in for sanitisation, heaters to 100% and waiting for boil. Tank temp 90℃.

1237 10 minute additions in.

1252 Boil finished, adding final additions and starting hop-stand.

1337 Charting chill from 85℃, aiming for 20℃.

1403 We’re at 20℃, starting transfer to Fermzilla.

1425 Transfer finished. I’m leaving behind a couple of litres because there’s a fair bit of trub, as such we’re looking at 19.5 litres on the Fermzilla’s scale to which I’ll be adding 1.7 litres starter. OG 1.052 (1.052 @ 17.9℃).

And Finally

Oh yes, that starter. I checked it first thing this morning and it was spinning away merrily with a bit of foam on top, reading 13℃ on my IR thermometer while the room was at 10℃. I moved it into the brewery just after dough-in because I wanted it to be nearer pitching temperature to reduce thermal shock, and throughout the day it rose to 20℃ (room at 15 – 18 ℃) slowing down the rate of bubbling as it did so. I’m guessing S-189 really is happier at cooler temps and I’m pushing my luck at 20℃, though I can’t get my wort much below that using the counterflow chiller, even in winter, and prefer to pitch sooner rather than continuing to chill the wort in the fermentation fridge. As always, fingers crossed.