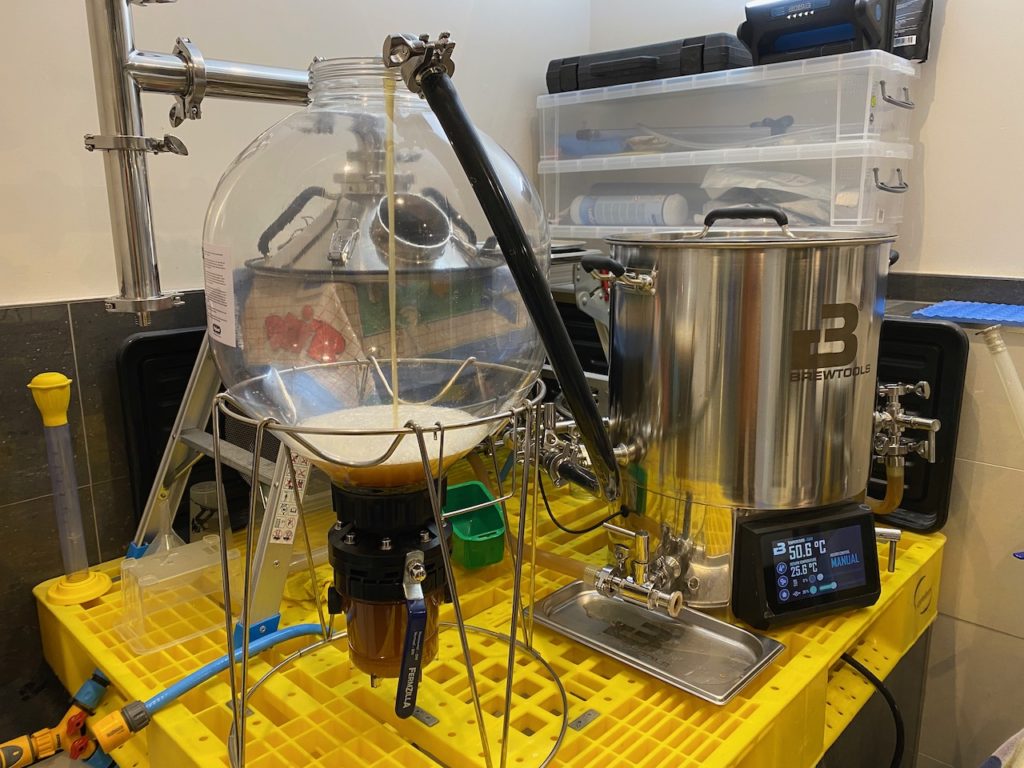

A fairly good brew day with no mishaps and me almost hitting all of my numbers, just a bit low on fermenter volume at just 20 litres which I’m putting down to inaccuracies between the kettle’s scale and that of the Fermzilla, and also some elevated trub losses since I started using the Trubinator for hoppy brews.

Trub Buster or Gimmick?

About that Trubinator. Essentially a cylindrical mesh barrier that’s dropped in towards the end of the boil, this device is supposed to keep all of the crud in the middle of the kettle and away from the dip tube, preventing it from being drawn into the FV once the wort is chilled. That’s all well and good, but there are two problems. Well, three if you count the minor pain that is cleaning the thing:

- If you have a second dip-tube on the return pipe then you can whirlpool while chilling, which also causes the trub to settle around the centre pipe, and

- The rubber skirt which holds the Trubinator central when it’s dropped into the kettle doesn’t seem to sit 100% flush to the base, leaving gaps here and there for the trub to get through as the kettle drains.

As a result I’m not convinced that the Trubinator in its present implementation is really worth bothering with, but no doubt Brewtools will in time improve on the design and come up with something brilliant, like their recent sparge attachment.

Mash Success

Apart from getting more and more efficiency out of my setup, something else that went right today was the thickness of the mash, which for the first time allowed wort to flow through from the centre pipe in a fan of liquid. Normally this is too much and results in the dip tube sucking air because the wort can’t flow through the malt pipe quick enough, but today I managed to keep the fan going pretty much most of the time, only shutting it off during stirring because otherwise mess.

Things were going so well in fact that I began to suspect a problem somewhere, but looking at my mash efficiency I scored 92 against a predicted 82, which is absolutely amazing. Predictably there’s a downside too, and in this case it’s that a mash that’s thin enough to allow a fast rate of throughput also drains pretty quickly during sparging. Good job then that I was using the aforementioned sparge attachment, which makes it easy to sprinkle all over the grain bed without resorting to bits of foil with holes punched in.

Transfer Process Refined

During a previous brew day I figured out that having the fermentation vessel on the floor (i.e. lower than the kettle) makes it difficult to regulate the rate of flow because gravity kicks in, and pulling wort too fast through the chiller results in the FV temperature being too high because the liquid doesn’t chill for long enough. I then started putting the FV on the same level as the kettle for transfer, but that quickly led to arm-ache, so now I’ve fixed it by adding a 90° elbow to the end of the transfer hose, letting me simply hook the hose onto the mouth of the FV.

#wisdom: once the kettle contents have been transferred to the FV, swapping the transfer pipe around so that the chiller can drain too yields approximately 1.5 litres over and above what’s in the kettle. Because these chiller contents can be recovered there’s no need to take chiller volume into account when filling strike water at the start of the day. (before – after)

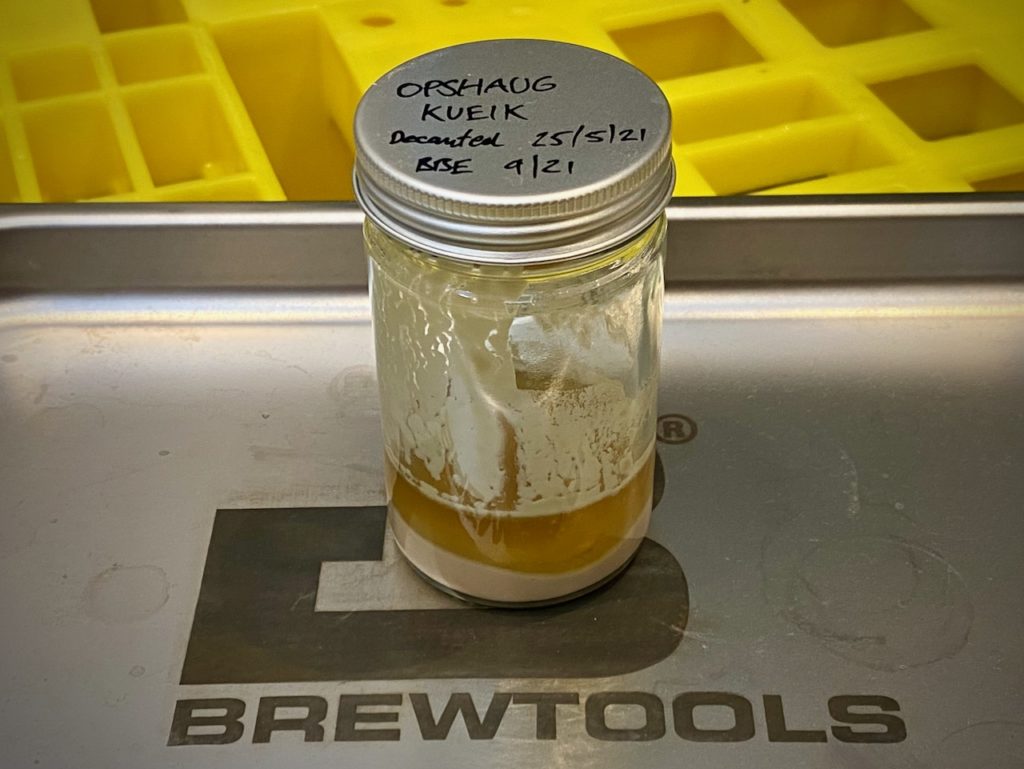

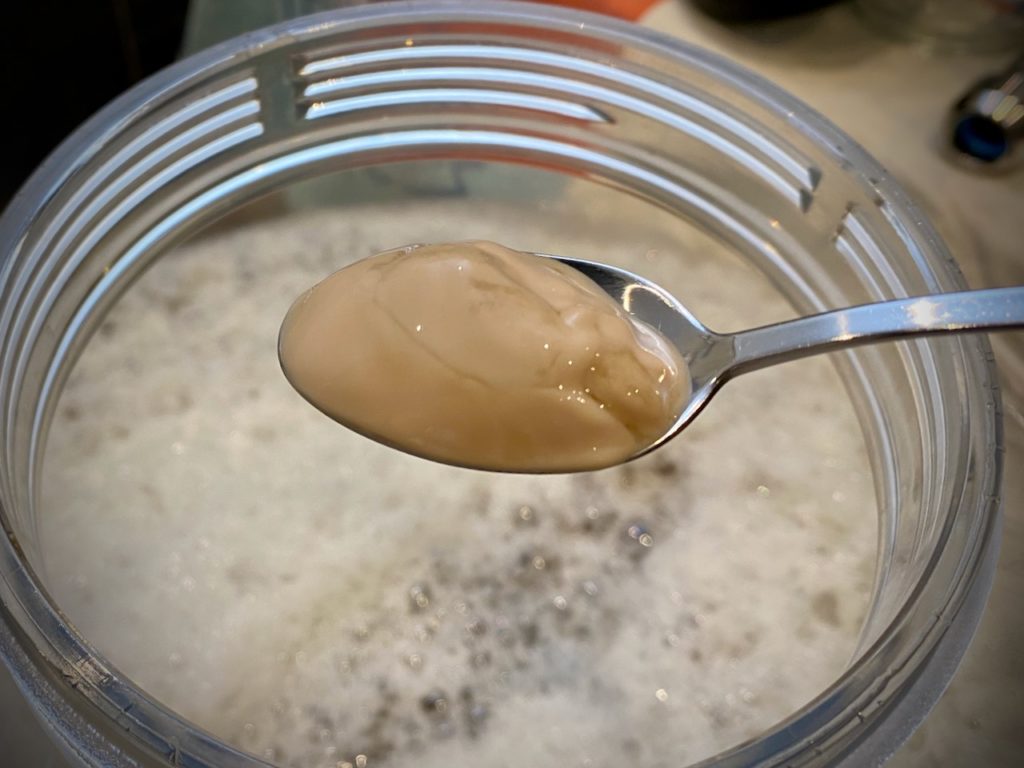

Last of the Summer Kveik

I’ve pitched the last of my Opshaug Kveik; approximately one heaped teaspoon which was left over from the sachet I purchased last May and has been sitting in my fridge ever since, now six months past the BBE date. The idea is that this might be just the right amount of under-pitching, thanks to the yeast’s age and amount, allowing the character to really shine through. Mind you, I’ve also gone in quite hard on the hops and am fermenting under pressure, so Opshaug isn’t getting 100% free reign. That’s the idea at least. Yeast was pitched at 12:00 this afternoon, and 5.5 hours on there’s still no sign. Not too worried about this (last time it took 12 hours for first signs) but it would have been nice to finally witness this yeast’s legendary prowess.

Brew Day Notes

0655 – Starting mash rest

0720 – Starting mash

0837 – Mash done. SG 1.062 (1.047 @ 58.5℃)

0847 – Starting sparge

0852 – Sparge done. 28.75 litres in the kettle (predicted 28.86) and SG 1.052 (1.035 @ 61.4℃ – predicted 1.046).

0930 – Boil tracker started, 60 minute additions in. Quite a thick hot break, now starting to dissipate. Read up (https://www.garshol.priv.no/blog/393.html) on Kveik while waiting for next addition, because I’ve only got a little bit left in the fridge and may want to harvest some. Looks like about 1/4 sachet in my little jar, and BBE was September last year, so 6 months ago. Think I’ll pitch all of this because I’m not 100% confident of the viability at this point, aiming for a general under-pitch in order to give it a good workout. Leaving jar at room temperature to acclimatise.

1001 – 30 minute additions in.

1018 – 15 minute additions in. Kettle volume is about 26.5 litres before cutting in chiller and Trubinator, expected 26.46. Nice. Pausing boil tracker while temperature builds up again.

1334 – 10 minute additions in.

1045 – End of boil, chilling to 80℃.

1050 – Start hop-stand, 20 minute additions in.

1115 – Hop-stand over, starting to chill from 80℃ to 30℃.

1119 – Return temperature already down to 31℃ so let’s start juggling the pipes and transferring to FV.

1140 – Transfer finished, looks like 20 litres on the Fermzilla’s scale. Forgot to measure post-boil gravity – oops! Sample hastily grabbed from FV reads 1.056 (1.055 @ 24.7℃) so I could have topped up a couple of litres and still hit my SG, but I’ve no bottled mineral water to hand and don’t fancy messing about with boiled water now that the yeast and Tilt have been unleashed.

1200 – Great, no signal from blue Tilt, swapping out for red.

1300 – Clean-up finished.