After many, many weeks of assembling kit, reading books and forums, ordering more kit, etc, I finally made it through my first ever all-grain brew day, starting yesterday after lunch and finishing up after nine o’clock. I kept a running log so that I could later dissect what worked and what didn’t, but first a bit about the beer.

Kona Big Wave Clone

I chose this one because I’ve always had a soft spot for a golden ale, and recent experience with Bure Gold reminded me just how incredible this style can be when it’s fresh on tap. The recipe I adapted is actually a clone of Kona’s ale which somebody else had designed, I just changed it very slightly to round off some numbers (e.g. 5g of Citra instead of 4.6g) once I scaled it up to 25 litres for the Fermzilla. Click here for the PDF recipe.

The Brew Day

By the time I started yesterday I’d already rehearsed the whole day several times so there weren’t many surprises, which was great. I noted down observations and took photos throughout the nine hour (!) ordeal and instead of writing those up into an epic account I’ll just paste them below for reference, drawing out some salient points that I need to work on.

The Good

Following a lot of research I was prepared for trouble in one or tow areas, but it actually went smoother than expected. One of those was the sparging, specifically the control of a continuous flow of sparge water to maintain an inch or so above the grain bed.

Sparging

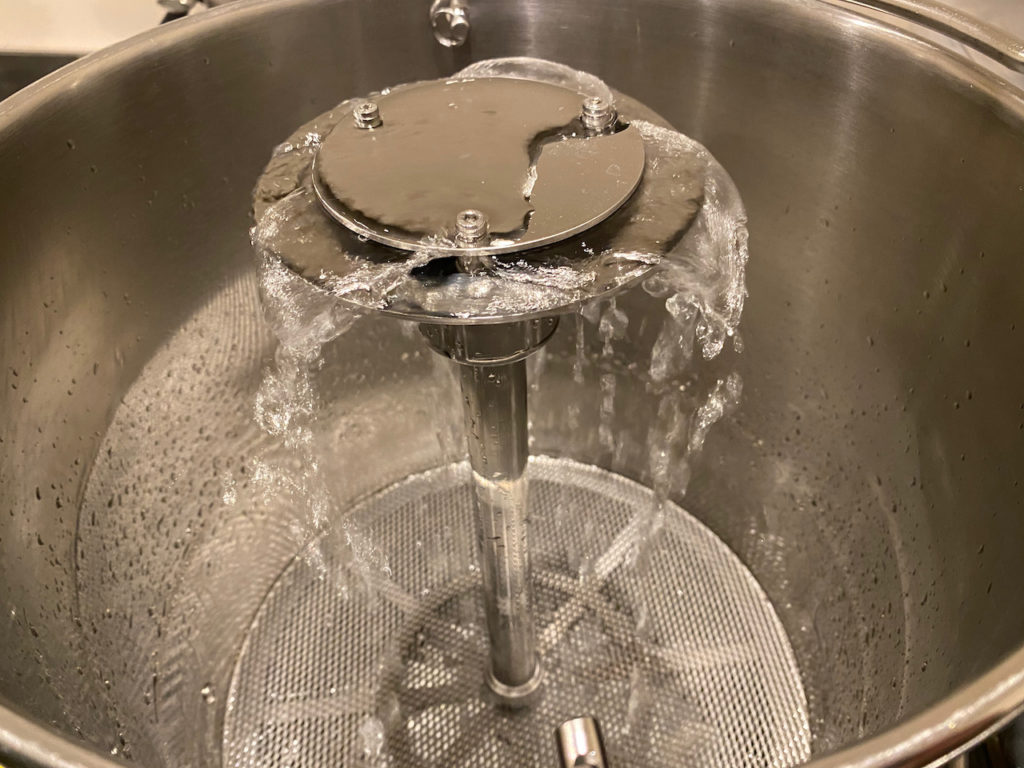

The B40Pro’s sparge hat dribbles water down the centre column at low flow and doesn’t really fan out until the flow is increased, by which point you’re putting too much water onto the grain bed and risk compressing it, thereby reducing the permeability and making things worse. The situation is further complicated by the way in which the sparge hat goes from dribble to fan – let’s refer to the transition as ‘fan threshold’ or FT for simplicity.

Increasing pump speed from 0 to 100% with the pump switched on will show you the FT quite suddenly, and by the time the flow of wort leaves the centre column and spreads out it does so with enthusiasm, splashing hot liquid onto the edge of the malt pipe and necessitating immediate throttling back to contain the flow. It’s a messy procedure not well suited to indoor brewing.

On the other hand, you can set the pump speed to a midway value with the pump still switched off, then switch it on abruptly instead of increasing it gradually. Using this method you’ll find the FT at a lower pump speed than if you were to increase it slowly, but you do run the risk of switching the pump on at too high a speed and now you’re soaked in hot wort. This FT sweet spot seems to be affected by the height of the malt pipe (hydrostatic head) and probably by wort composition and temperature as well, so you really do have to get a feel for it and play around.

In the end I wasn’t able to find a continuous flow rate that maintained one inch of sparge water above the grain bed while also distributing that water sufficiently, and resorted to switching the pump on as soon as the first grains became exposed, and off again when the inch was reached. I did this at a rate just past FT (third image above) so that when the water was running it was well distributed. The approach worked really well and I can’t see any issues since the grain bed was neither allowed to dry out or excessively compacted, so until somebody points out an oversight I’m going to chalk this one up as a success.

Boiling

After the sparge it was time to boil, and I was nervous because I’d seen plenty of references to boil-over, where the kettle suddenly and without warning goes mental and you end up with a sticky mess. My nervousness wasn’t helped by the fact that I had to do this in manual mode, because automatic mode tops out at 90 ℃ and has no way of telling when the wort boils anyway.

In the end I needn’t have worried. It took quite a while to get up to a rolling boil despite the heater on 100%, then I was able to maintain the boil by reducing power to 85% and keeping an eye on it, which is easier said than done when you’re using a steam hat + condenser and can’t see the wort without removing the rubber bung, which in turn affects the boil temperature. I’ve heard of people starting on their cleaning duties while the boil is in process, but I just didn’t have the confidence to leave it alone. Maybe I’ll get there with the kind of experience that follows several uneventful brews, but for now I’ll stick to the old adage that a watched pot never boils.

Brewfather

Last but not least I have to say that the Brewfather app and website are probably the biggest contributors to yesterday’s positive outcome. Finding and adapting a recipe was a cinch using the web UI on the laptop, I did my picking from inventory using the iPad app, and used the app on my iPhone to keep track of various stages via the recipe-driven timers. Everything synchronised flawlessly across devices and kept me on track despite having no experience and a good amount of nervousness. The only thing that was missing was a reminder to switch on the counterflow chiller 15 minutes before end of boil so that it has a chance to sanitise, but that’s my failing and not Brewfather’s.

The Bad

Invariably there were some mistakes, but they weren’t as severe or numerous as I’d feared. I’m already working out how to address these and next time around should have eliminated all of them, but let’s call them out – warts ‘n all.

Power Supply

I don’t have electricity in the brewery, so it’s a case of running the fridge, kettle (B40Pro), and sparge water heater (20 litre Cygnet) off extension leads. It’s a hideous cowboy setup made all the worse by my electrical qualifications, but it’s a calculated risk and a means to an end. I’m using one 13A reel (unwound, naturally) for the water heater, and that has a thermal cut-out which it doesn’t trip, but when I use that lead with the B40Pro it does trip. So the trippy reel is saved exclusively for the Cygnet.

The B40Pro is on the same 13A extension which serves the fridge, and of course I should have unplugged that fridge before entering the boil stage. The heating elements are capped at 50% power during mashing so as not to scorch any grains that make it through the malt pipe’s false bottom, but when they’re running at full chat to reach boiling temperature the B40Pro does draw damn close to 13A, resulting in some heat build-up in cables and sockets. (I discovered it would trip the other reel’s thermal cut-out during a test run)

Everything was going swimmingly until the fridge decided to run its compressor while the B40Pro was boiling, and that blew the fuse in the extension cord serving those two devices. Stupid, predictable, and now I was paying for it by looking for another 13A lead of sufficient length with my boil timer ticking and the kettle not boiling.

#wisdom: if you have to use extension leads, unplug absolutely everything else. The fridge can take care of itself for a couple of hours, the brew kettle can’t. (you knew this already, you complete and utter pilchard)

Mashing

All I knew was that for 20 minutes after dough-in you should rest the grains, and neither stir them nor circulate water through them. Brewtools are very specific about this in their instructions, and during a few of the video reviews of this kit I’ve seen on YouTube the brewers who haven’t rested their mash have expressed difficulty later on with matter getting through the mesh bottom or with sparging.

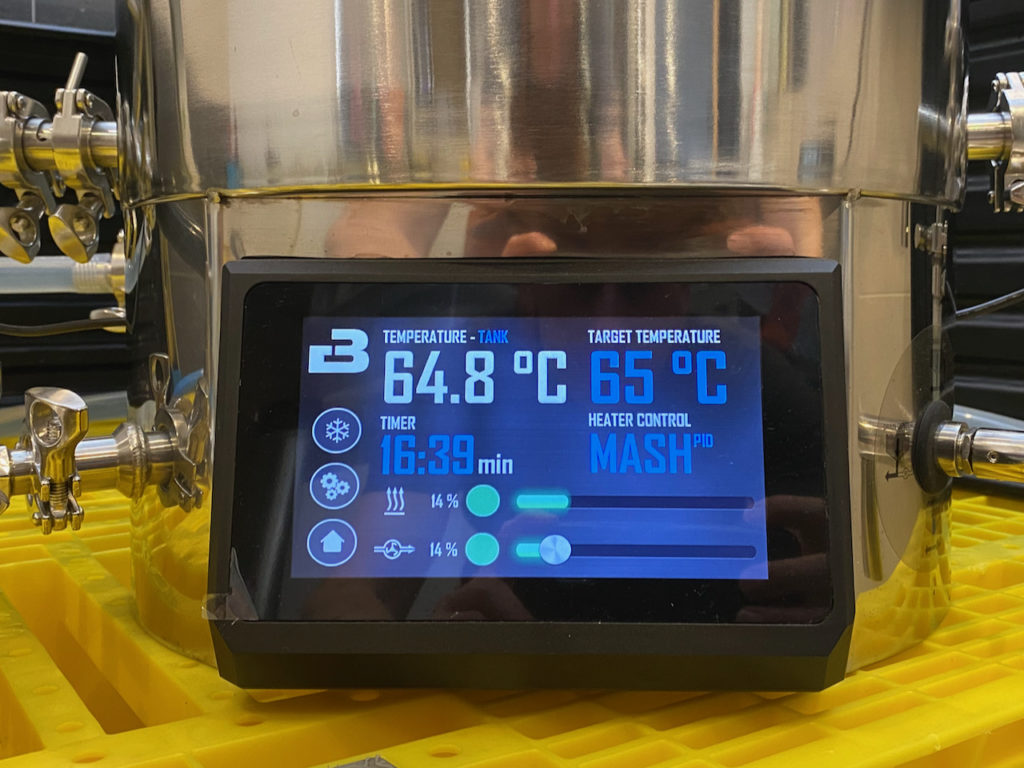

What Brewtools aren’t specific about is whether that 20 minutes is in addition to your mash time, or part thereof. Being paranoid of possible side-effects of an extended mash (tannins, those dreaded tannins!) I guessed those 20 minutes should form part of the mash, and just sat there staring at the grain bed while 65 ℃ water circulated outside the malt pipe. There were two problems here, and I think a combination of both of them led to lower-than-expected pre-boil gravity.

- Some of the grain had come to rest above the water level and remained dry during the whole 20 minutes, ⅓ of my total mash time. I think I could have given the very top layer the gentlest of stirs at dough-in just to get everything covered without causing whatever I was supposed to avoid by not stirring.

- My mash temperature was between 62 and 63 ℃ as measured using a digital thermometer, whereas the strike temperature was set to 65 ℃ on the B40Pro. Each time you turn this thing on it starts with default values, and for auto mode the default target temperature is always 68 ℃. That should have been a hint for me to leave well alone, since no matter how well you circulate you will always have a few degrees less inside the mash than on the outside, which is where your thermometer is. Especially if you’re not even circulating any water through the mash for the first 20 minutes.

#wisdom: next time, heat strike water to 68 ℃ and see if the mash reaches your actual target of 65 ℃. Dumb-ass.

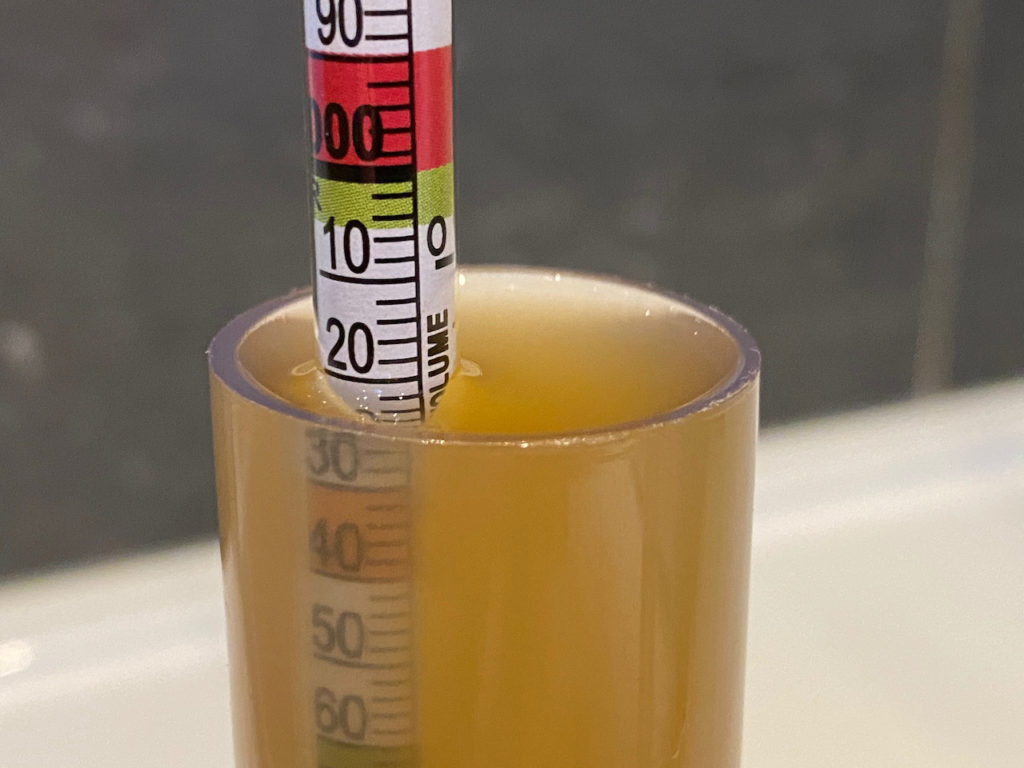

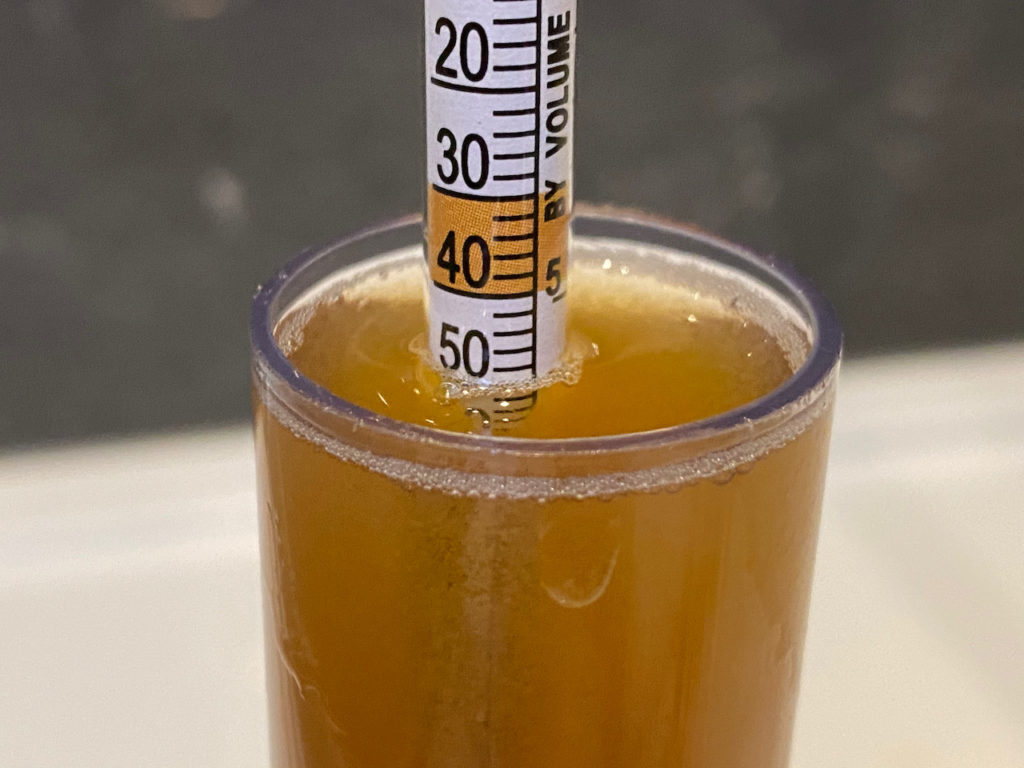

Pre-boil Gravity

In hindsight I’m now convinced this is connected to my mashing, but I got a value of 1.020 for pre-boil gravity when I was expecting 1.044. That was a pretty low moment and I wondered if I should abandon it there and then rather than throw more time and ingredients at something that was going to turn out substantially weaker than expected. I knew that my hydrometer was calibrated at 20 ℃ and I was measuring at 65 ℃ so there was bound to be a difference, but I assumed it would be a minor difference. A quick plea for help on the forum revealed that there is a calculator for working out temperature offset in SG readings, and that the difference can be quite substantial: my 1.020 was actually 1.036 (Brewer’s Friend) or 1.038 (Brewfather … yeah, the one in your app, idiot)

All was not lost, and I reckon I could still get a light session beer out of this brew, even if it wouldn’t be the same as the legendary Big Wave. In the end I finished with a post-boil gravity of 1.050 versus an expected 1.047, so as long as the extra few points aren’t due to some yet to be discovered cock-up I may well have gotten away with it.

#wisdom: always, always adjust gravity readings for temperature, ideally by leaving the sample to cool naturally or by using a calculator. There’s not much point when you’re one or two degrees outside the hydrometer’s calibration temperature, but it soon becomes worth doing.

Measuring Liquids

Need to get a measuring jug and work out equipment offsets. I ‘measured’ my strike and sparge water using a 5 litre bottle and a 1 litre bottle when I should really have used a proper jug. I also need to account for plumbing voids like the counterflow chiller since that swallows strike / sparge water as well as fermentables, unlike boil-off losses which leave fermentables behind and affect gravity. (oddly enough, there’s another calculator for that too)

#wisdom: be specific in your measurements, try to account for all voids and losses. Leaving this one as #unsolved since I need more info.

General Timing

There’s still so much that I don’t know, that when I hear things like ‘you shouldn’t sparge too quickly because it compresses the grain bed’ I start to worry about other things which may not even be problems at all. Like going from sparge to boil.

Yesterday I gave the malt pipe a few minutes to drain before lifting it clear, but that was just because I didn’t want to dribble sticky wort between the B40Pro and the awaiting bucket. When I was clearing up at the end of the day I noticed there was about a litre of wort in the bottom of that bucket, some of which should by now have been in my fermenter.

As it stands my post-boil volume was 2.17 litres short, some of which might have been due to the counterflow chiller, and some might have been in that bucket. Should I have waited longer for the malt pipe to drain? Should I have squeezed it slightly? Both options occurred to me at the time, both were discounted because fear of the unknown (tannins? astringency?) was greater than fear of the known: being a couple of pints short.

If I start picking apart the ifs and buts in order to derive specific #wisdom points covering ‘general timing’ I’ll never finish this post, so let’s write this off as something that will get better by itself with experience.

The Detail

Here’s the raw log I kept on the day, with photos too in chronological (rather than useful) order added in. The iPad is a frustrating device when it comes to writing notes, but at least it has a splash-proof keyboard.

Preparation

12:50 – Fill sparge water heater with 15 litres cold tap water (3x Ashbeck bottles), set dial to 3, plugged into Masterplug cable reel but expect thermal cut-out to trip at some point. Water temperature 11.5.

13:15 – Sanitised Fermzilla and finally got around to applying the graduated level scale

13:25 – Scaled the batch recipe for 25 litres (Fermzilla headspace looks to be enough) and adjusted the fermentables and hops a little to round the scaled values and bring IBU / EBC sliders to mid-points.

13:30 – Water heater clicked off gracefully, temperature 66.0. Need 65 for mash so I’m going to give the kettle and coils a quick rinse before bringing in the strike water and topping up.

13:55 – Moved 15 litres from water heater to kettle, replenished kettle with 7.5 litres, resumed heating.

14:15 – Grabbed the malt from stores and noticed that mash water in kettle was 24.75 litres. Maybe Ashbeck bottles aren’t the best measuring vessels! Reduced to 22.57 using scale inside the kettle, malt pipe in place. Refilled the water heater with 11.75 litres for sparging, again with Ashbeck bottles, but not brimmed. Need to get myself a decent measuring jug! Started heating sparge water.

14:17 – Started heating strike water in ‘mash’ heating mode, target 65.0, starting at 55.0. There’s no grain in there yet so I could set it to full auto (instead of ‘mash’ where the elements are capped at 50%) but I’m not in a hurry as I want to go get the hops and Protafloc tablet.

Dough-in

14:52 – Ingredients measured and bagged, commencing dough-in. First 20 minutes are there to settle, no stirring, timer starts when they’re all in.

Mashing

15:06 – Dough-in complete, starting 60 minute mash timer. I’m putting the lid on until I’m allowed to stir / circulate over the mash in 20 minutes time.

15:20 – 5 minutes left until I can stir and switch on the centre pipe to circulate over the mash. Checked the manual again just to be sure, and yes, only circulating outside for first 20 minutes to prevent sugars scorching on the elements. Weird, because there’s a bit of the mash that’s not even wet yet. 3 minutes.

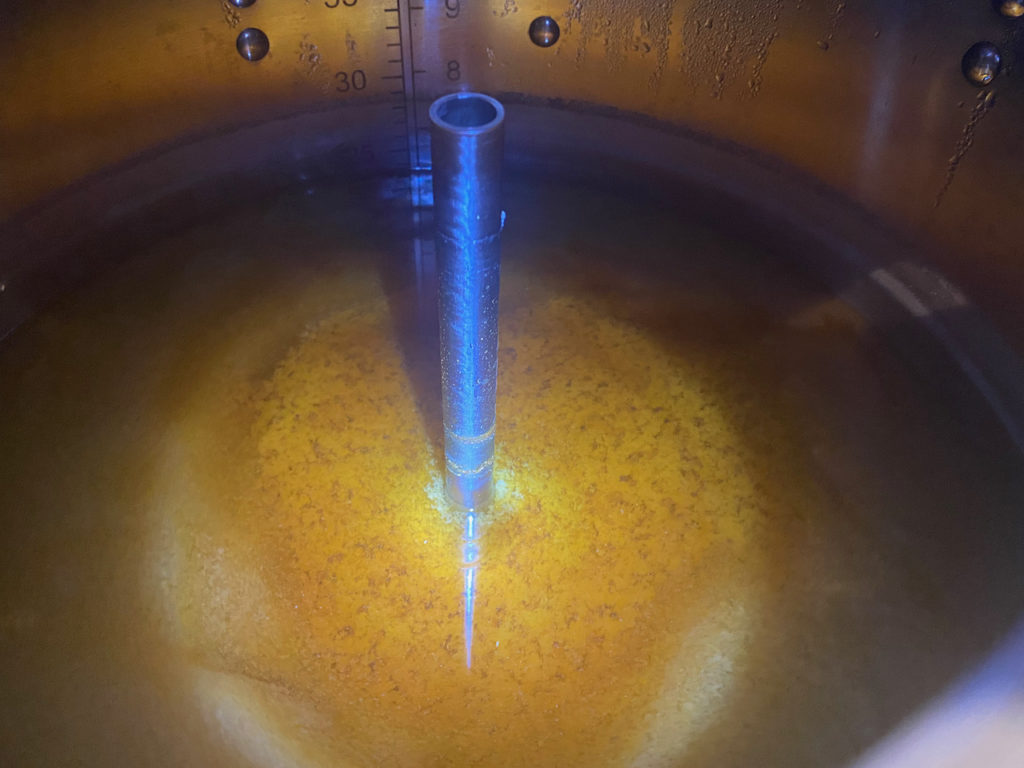

15:24 – Starting to circulate over grain bed and stirring. The mash isn’t as dense as I feared, those dry grains on top at the start soon went under with a gentle stir. Dividing the flow between circulating outside the malt pipe and over the grain bed is a fine balance, didn’t take long before I started sucking air via the thankfully correctly adjusted dip tube. Weight of water on the grain then compacts it further at the bottom, so it needs stirring lower down – something I was hoping to minimise in order not to push too much solid matter out through the screen. Oh well, at least there are no dough balls. Dare say I’ll find the perfect balance with practice.

16:00 – 5 minutes left to go, and I have the pump at 77%, valve halfway between recirculating outside malt pipe and up centre. Nice parasol of wort going on, malt pipe level about 4 inches higher than outside. I know stirring will lower that, but I don’t want to agitate too much and drive solids through the mesh. Also don’t want a stuck sparge. Decisions, decisions …

16:07 – Mash complete, heater and pump off while I raise the malt pipe. Inside / outside levels adjust quickly enough.

Sparging

16:13 – Try brief vorlauf but the pump seems to stick, cycling it on and off clears it, then it sticks again. Switching to sparge, water temp 76.5.

16:16 – Maintaining an inch of water on grain bed is not easy. Pulsing pump at 45% seems to do it.

16:19 – Sparge complete. Leaving grain pipe for a minute to drain – was heavy lifting it up after mashing.

Prepare for Boil

16:27 – Boil volume is only 28 litres (should be 31.5 according to Brewfather) and gravity a measly 1.020 when it should be 1.044. Bollocks. Should I have mashed for longer? Sparged with less? Oh well, let’s boil and see what happens. Might be more of a low ABV session ale after all.

16:30 – Fitting condenser and steam hat, starting approach to whatever boil temperature is, presently at 60.

Boiling

17:08 – That took a while to get there! Extension lead / socket are getting very warm now – I’m on the regular 13A white one since the reel would have thrown its thermal trip by now. 60 minute timer started (still wondering if I should increase that to bring FG up) and 60 minute hop additions done.

Had some advice from the guys on the forum who confirmed that yes, temperature makes a huge difference to SG readings. I plugged my values into a calculator I was offered and it seems I’m actually at 1.036, not 1.020. Happy days!! Still low, but not a disaster.

17:32 – Rolling boil is thankfully uneventful. Keeping a constant eye open for boil-over or a melting socket. Steam hat and condenser doing their ting. I’m on my 4th bucket of warm water now, saving it for cleaning later. Managing heater manually between 85 and 100%, trying to keep the boil going on lowest value possible.

17:51 – I’m two minutes away from next boil additions and the extension lead just crapped out. Switching over to the reel, wondering how long I have before the thermal switch trips. To be fair it was the first lead (also powering the fridge) which seems to have gone, since the fridge is dead. Maybe 90% heating and fridge was too much? Sounds very plausible – I should have thought of that and switched the fridge off for the boil.

17:55 – Added one third of a Protafloc tablet. Adjusted value was 0.272 from recommended one quarter.

18:05 – 5 minute boil additions are in, smells fantastic. Hang on in there little power reel!!

Chilling

18:09 – Heaters off, start counter flow chilling. Temp 100C.

18:10 – Shit, forgot about sanitising the counter flow chiller for the last 15 minutes!! Let’s give it 5 and hope for the best, was Star-san’ed after all. Heaters back on, hope the power stays on too… Temp 94.5 through chiller.

18:15 – Enough, heaters off again, time to chill or we lose the hops.

18:17 – Counterflow chiller amazing, return temperature already down to 42, tank at 75.

18:21 – Return temp down to 30, tank at 47. Hard to know how to best set the return dip tube and pump speed; faster pump will probably be better for whirlpool but slower pump gets return wort cooler faster. I’m trying to eyeball the kettle contents and get a feel for the balance, but it’s iffy.

Transfer to Fermenter

18:26 – Return is now at 20, tank at 31. I’m stopping the pumps and plumbing in the Fermzilla. Will transfer slow-ish with a bit of splashing since I don’t yet have my oxygen setup. Kettle level is 24 litres, but then I didn’t factor in the chiller.

18:37 – Transfer to FV going well, but guess who forgot to adjust the dip-tube? Using mash paddle to push it down while holding / splashing transfer hose above Fermzilla, let’s hope there are no sanitation issues

Pitching Yeast

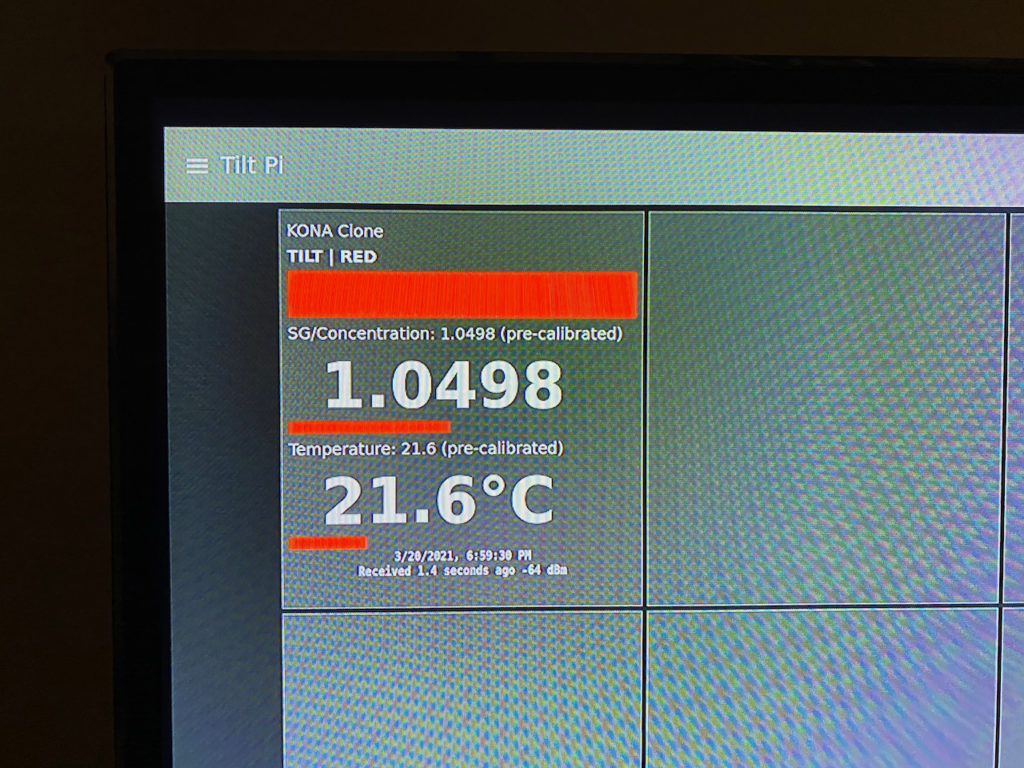

18:51 – Yeast pitched at 21.5 degrees, FV volume 21.5 litres. OG 1.050 is OK by me against expected 1.047. Sanitised Tilt deployed, time to clean up.

19:45 – Stopped cleaning in order to have dinner

20:10 – Cleanup resumed

21:20 – Everything’s clean. Jesus. What a day.